Kamar yadda muka sani, a cikin masana'antar kera injuna na zamani, kamfanoni suna da buƙatu da yawakayan aikin inji na musamman. Gabaɗaya, injunan hakowa na yau da kullun suna da babban ƙarfin aiki, ƙarancin aiki na musamman, ƙarancin aiki kuma babu garantin daidaito; yayin da na musamman Multi-ramiinjin hakowasun dace, mai ceton aiki, mai sauƙin ganewa, kuma ba sa fuskantar kurakurai da gazawa. Ba za su iya rage gajiyar ma'aikata kawai ba, da kuma tabbatar da amincin ma'aikata da injinan hakowa. Yana da aminci kuma yana iya haɓaka aikin injin hakowa. Tare da ci gaba da ci gaban kimiyya da fasaha,na'urorin hakowa na musammanana amfani da su sosai a masana'antu. A takaice dai, mafi ƙarfin ƙwarewa, mafi kyawun kamfani zai iya ba da tabbacin ingancin samfuransa. Don haka, yin amfani da na'urori na musamman na na'ura na taka muhimmiyar rawa a fagen gasa na kamfanoni.

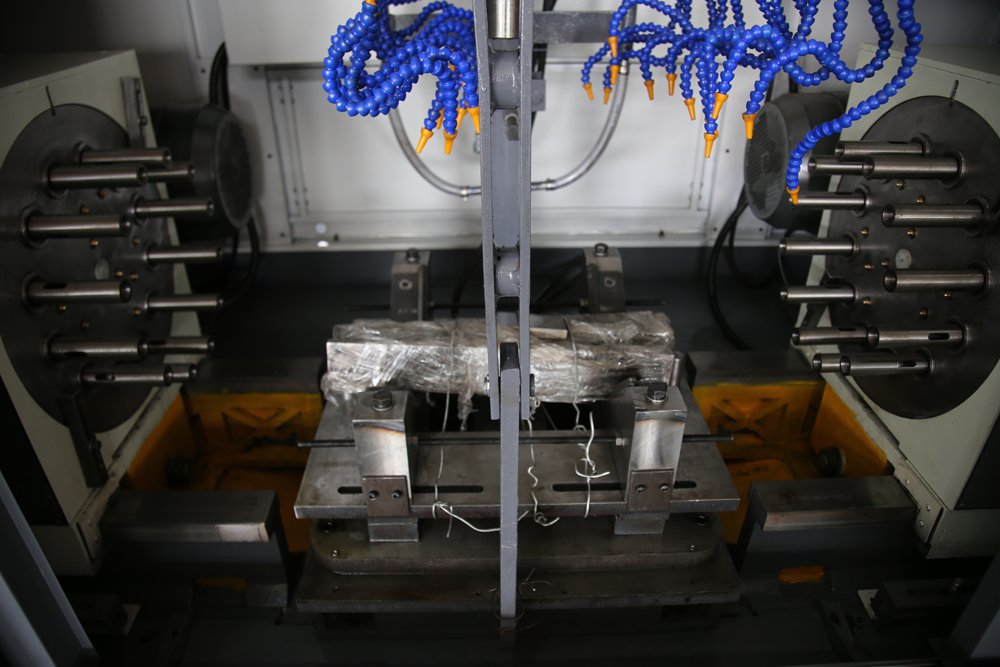

TheMulti-rami hakowa injisamar da mu factory ne musamman da nufin abawul masana'antu. Yana iya gane kowane irinbakin kofa, malam buɗe ido, sarrafa bawulolida sauran bawuloli. Ƙarfe mai gefe uku ko biyu da aka yi da ƙarfe ko simintin ƙarfe na iya zamaya huda aka bugaa lokaci guda. Bugu da kari ga ban mamaki karuwa a bawul yadda ya dace, sauran manyan aikace-aikace yankunan, kamar sarrafa famfo jikin, auto sassa, injiniya inji da sauran sassa, kuma za a iya amfani da lokaci guda hakowa na karshen ramukan, tsakiyar ramukan, tapered ramukan da kuma tapered ramukan. mai siffar zobe ramukan a kan workpiece. sarrafa rami. Multi-ramin ramiYana da nau'ikan samfuran guda biyu da kuma tsarin sarrafa tsarin sarrafawa, wanda zai iya fahimtar atomatik, babban daidaitacce, da samarwa iri-iri, da samarwa da yawa, da samarwa da yawa, da samarwa da yawa, da samarwa da yawa, da samarwa da yawa, da samarwa da yawa, da samarwa da yawa, da samarwa da yawa, da samarwa da yawa, da samarwa da yawa, da samarwa da yawa, da samarwa da yawa, da samarwa da yawa, da samarwa da yawa, da samarwa da yawa, da samarwa da yawa, da samarwa iri-iri.

Hakanan akwai wasu matakan kiyayewa yayin amfaniMulti-rami drills. Mun yi taƙaice mai zuwa don haka:

1) Dole ne a daidaita ma'aunin rawar jiki a daidaiku kuma a haɗa shi, kuma dole ne a daidaita shi sosai yayin sufuri don guje wa girgizawa da karo.

2) Don auna diamita na rawar rawar soja, yi amfani da kayan auna mara lamba kamar na'urar microscope don guje wa rauni ta hanyar haɗin injin.

3) Themulti-spindle hakowashugaban wutar lantarki dole ne ya yi amfani da zoben sakawa na hakowa yayin amfani, ta yadda za a gyara elongation na rawar rawar sojan da aka sanya a kan sandar ta zama daidai. Multi-spindleinjin hakowadole ne a mai da hankali sosai ga wannan batu, ta yadda zurfin hakowa na kowane igiya dole ne ya zama Haɗa kai.

4) Duba lalacewa na yankan gefen rawar soja.

5) TheMulti-rami hakowa injiya kamata a duba ta'aziyyar sandal da chuck akai-akai. Rashin daidaituwa mara kyau zai haifar da ƙananan diamita don karya kuma ƙara diamita ramin. Ƙarfin maƙarƙashiya mara kyau zai haifar da ainihin gudun ya saba da saurin da aka saita. Za a sami zamewa tsakanin raƙuman rawar soja.

6) Tsawon matsewar ɗigon ramuka mai yawa akan chuck shine sau 4 zuwa 5 diamita na shank ɗin rawar sojan da za a ɗaure da ƙarfi.

7) Koyaushe bincika sandal. Ba za a iya girgiza babban shinge ba don hana fashewar ramuka da ramukan ramuka yayin hakowa.

8) Tsarin sakawa a kan benci na ɗigon ramuka mai yawa yana da tsayin daka kuma an shimfiɗa shi, wanda ya tsawaita rayuwar aikin rawar jiki kuma yana rage farashin samarwa da kashe kuɗi. Sakamakon niƙa mai yawa ba shi da amfani.

Lokacin aikawa: Nuwamba-20-2021