Wannan labarin yafi gabatar da high-inganci aiki Hanyar manyan-sikelin karfe tube takardar ramin kungiyoyin amfani a cikin manyan sikelin dauki tasoshin da zafi musayar a cikin man fetur da kuma sinadaran masana'antu. Zaɓin na'urori masu ban sha'awa na gargajiya da na niƙa da radial drills ba su sami damar cimma buƙatun ingantaccen inganci ba, balle ma buƙatun daidaito. BOSM babban nauyi mai nauyiFarashin CNCkuma injinan niƙa an kera su musamman kuma ana kera su a wannan masana'antar. A halin yanzu, ya samu na farko sa na BOSM-DS8585 a kasar, wanda zai iya gane matsakaicin workpiece diamita na 8500mm, da kuma karami model ne 6000×6000, 5000×5000, 4000×4000, 3000×3000, 2000× 2000 da 1000×1000.

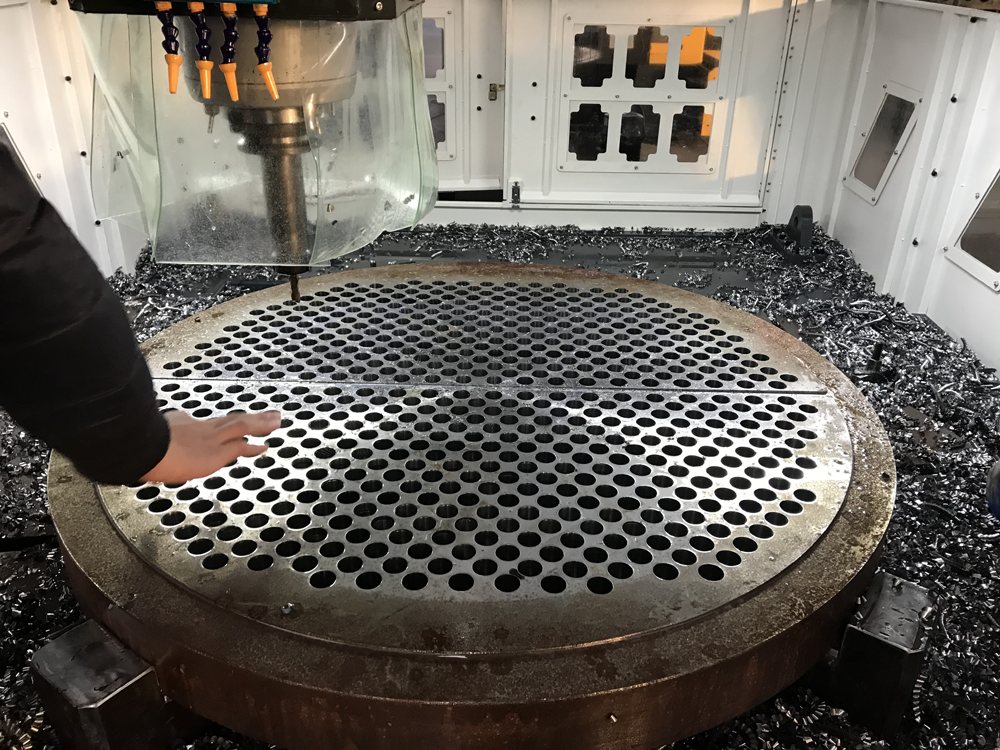

Matsa farantin bututu a kanCNC hakowa da injin niƙa, Shigar da ramin rami na matukin jirgi a kan na'urar hakowa da injin CNC, fara hawan CNC dainjin niƙa, da kuma amfani da CNC hakowa da milling inji don aiwatar da duk tube ramukan a kan bututu farantin da matukin jirgi zurfin 20 ~ 30 ㎜ , Domin tabbatar da matsayi daidaito naramukan tubeakan babban takardar bututun ƙarfe.

Hanyar sarrafa manyan sikelin karfe tube takardar rami kungiyoyin bisa ga bukatun, halin da cewa diamita na tube takardar ne 5000 mm ~ 8000 mm, da kauri ne 50 mm ~ 250 mm, da kuma abu ne GB150.2 "Material. na kashi na biyu na jirgin ruwa” ƙayyadaddun kayan ƙarfe; dubban dubun duban ramukan ramukan tube kozafi musayar bututu ramukanan shirya su a kan farantin bututu don samar da ramuka masu yawa da aka shirya bisa ga wata ƙa'ida.

A cikin tsarin sarrafawa, idan an yi amfani da rawar jiki na radial, aikin aikin zurfin zurfin ya zama mafi wahala, kuma ƙarfin amsawa ba zai iya gamsuwa da karuwa a cikin adadin abinci ba. Saboda rashin ƙarfi na tsayin rawar rawar jiki, idan an yi amfani da tsayin daka kai tsaye don rami na farko, ƙarfin amsawar gwajin farantin bututu zai iya haifar da tsayin daka don lanƙwasa, kuma ɗan tsayin zai iya lanƙwasa a ƙarƙashin ramin. jujjuyawar ƙarfi, kuma ɗan tsayin daka yana juyawa. Jitter na kewayawa ya fara bayyana a cikin yanayin, ko da yake an rage yawan jitter bayan hakowa zuwa wani zurfin zurfi, jagorancin tafiya na gaba na gaba ya bambanta daga yanayin da aka sa ran zuwa ƙasa, wanda ya haifar da rami na ƙarshe a cikin bututu. rami mafi girma kuma mafi kauri takardar bututu Faɗin gada ya wuce misali. Akasin haka, idan kun yi amfani da aFarashin CNCda injin niƙa, yi amfani da rawar U, wanda ke da tsauri mai kyau da ruwa daga tsakiya. A lokacin hakowa na farko, muddin ana sarrafa adadin abinci, hakowar ba za ta tanƙwara ko karye ba.

Farashin BOSMCNC hakowa da injin niƙayana maye gurbin rawar radial na gargajiya don sarrafa manyan manyan zanen bututu. Lokacin aiki na CNC hakowa dainjin niƙakashi 23.5% ne kawai na na aikin radial. CNC hakowa ba kawai ya 'yantar da ma'aikata, amma kuma ƙwarai inganta samar da inganci. Radial drills ba zai iya sarrafa zanen bututu mai kauri ba. Misali, idan kauri ya wuce 300mm, dole ne a sanye shi da injin hakowa na CNC da injin niƙa tare da U-drills. Saboda rawar radial ba zai iya shawo kan rashin lahani na yankan ƙarfe mai dawowa zuwa sama ba, ingancin takardar bututun kuma zai yi tasiri sosai.

Lokacin aikawa: Nuwamba-20-2021