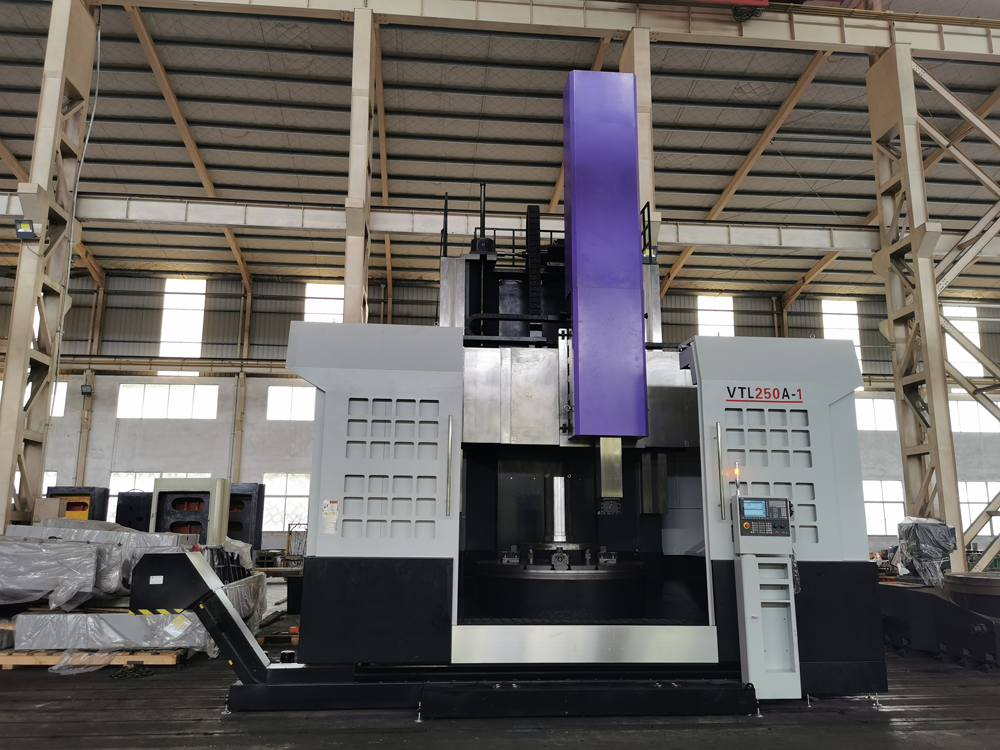

Babban-sikelinCNC lathes a tsayemanyan injuna ne, waɗanda ake amfani da su don aiwatar da manyan kayan aiki masu nauyi tare da manyan radial girma da ƙananan ƙananan axial girma, da hadaddun siffofi. Alal misali, cylindrical surface, karshen surface, conical surface, cylindrical rami, conical rami na daban-daban fayafai, ƙafafun da kuma sets na workpieces kuma za a iya sarrafa tare da taimakon ƙarin na'urorin ga threading, mai siffar zobe surface, profiling, milling da nika.

Lokacin taimako na babban-sikelinInjin CNC VTLgajere ne sosai. Yana iya kammala duk abubuwan da ake sarrafawa a cikin matsi ɗaya. Yi ƙoƙarin zaɓar madaidaicin buɗaɗɗen tare da tsayi mai tsayi, wanda ba zai iya tsoma baki tare da hanyar kayan aiki ba, kuma yana iya kammala aikin sarrafa kayan aiki a cikin kewayon bugun bugun sandar. A matsayin kayan aikin inji mai sarrafa kansa, ƙararrawa iri-iri za su bayyana bayan ɗan lokaci na amfani. Wasu gazawar tsarin ne, wasu saitunan sigina mara kyau, wasu kuma gazawar inji. Ƙararrawar fan na ɗaya daga cikinsu.

Lokacin da irin wannan yanayin ya faru, duba fan na ciki da farko. Idan bai juyo ba, a ware shi ku gani. Idan ya yi datti sosai, a goge shi da barasa ko man fetur kafin a saka shi. Idan akwai ƙararrawa, dole ne ka maye gurbin servo amplifier. HC ya bayyana. Ƙararrawa na yanzu, musamman don gano ƙarancin halin yanzu a gefen DC, fara duba sigogin servo, sannan cire layin wutar lantarki. A cikin lokacin, akwai ƙararrawa don maye gurbin servo amplifier. Babu ƙararrawa. Musayar motar da layin wutar lantarki tare da sauran axis don sanin ko motar ce ko layin wutar lantarki. Matsala: Idan J ya bayyana akan nuni, ya dogara da ko matsalar PC ce. Bincika ko motherboard, allon musayar bayanai da na'urar kula da PCRAM daidai ne, maye gurbin kuma cire kuskure har sai an gano dalilin, sannan a warware matsalar.

Lokacin da irin wannan yanayin ya faru, duba fan na ciki da farko. Idan bai juyo ba, a ware shi ku gani. Idan ya yi datti sosai, a goge shi da barasa ko man fetur kafin a saka shi. Idan akwai ƙararrawa, dole ne ka maye gurbin servo amplifier. HC ya bayyana. Ƙararrawa na yanzu, musamman don gano ƙarancin halin yanzu a gefen DC, fara duba sigogin servo, sannan cire layin wutar lantarki. A cikin lokacin, akwai ƙararrawa don maye gurbin servo amplifier. Babu ƙararrawa. Musayar motar da layin wutar lantarki tare da sauran axis don sanin ko motar ce ko layin wutar lantarki. Matsala: Idan J ya bayyana akan nuni, ya dogara da ko matsalar PC ce. Bincika ko motherboard, allon musayar bayanai da na'urar kula da PCRAM daidai ne, maye gurbin kuma cire kuskure har sai an gano dalilin, sannan a warware matsalar.

Menene abubuwan da ke buƙatar kulawa a cikin kiyaye manyan CNCFarashin VTL?

1. Bayan fara babban motar a kowane lokaci, ba za a iya kunna sandar ba nan da nan. Sai bayan famfon mai yana aiki akai-akai kuma taga mai ta zo da mai, za a iya fara mashin ɗin don barin na'urar ta yi aiki.

2. Za a iya amfani da dunƙule kawai lokacin juya zaren don tabbatar da daidaito da rayuwa.

3. Kula da ciki da waje nakayan aikin injindon zama mai tsabta, sassan injin sun cika, sandunan dunƙule da sanduna masu gogewa ba su da mai, kuma saman dogo na jagora suna da tsabta kuma ba su da kyau.

4. Yi aikin lubrication na kowane ma'aunin lubrication bisa ga ƙayyadaddun buƙatun (duba alamar lakabin tsarin lubrication na na'ura don cikakkun bayanai).

5. A kai a kai duba da daidaita tightness na V-bel naCNC lathe a tsaye.

6. Kula da duba yanayin aiki na famfo mai don tabbatar da cewa akwatin kai da akwatin abinci suna da isasshen man mai. Man mai da ke cikin kowane tanki kada ya kasance ƙasa da tsakiyar kowace ma'aunin mai, in ba haka ba kayan aikin injin zai lalace saboda rashin lubrition.

7. Tsaftace tace man jan ragamar tagulla na tace mai a cikin mashin ɗin mai na akwatin gado kowane mako don tabbatar da cewa mai mai ya kasance mai tsabta.

8. Lokacin da igiya ke jujjuya a cikin babban gudu, a cikin wani hali bai kamata ku ja hannun motsi ba.

Lokacin aikawa: Nuwamba-24-2021