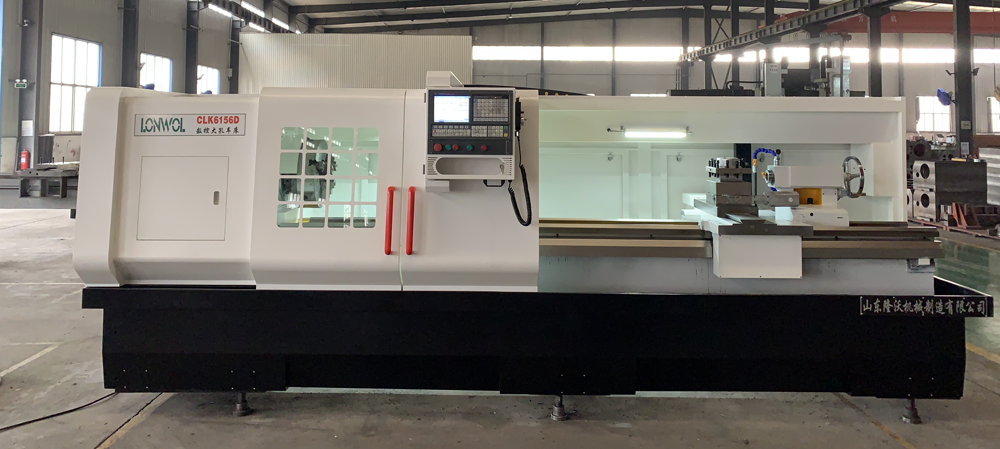

Wannan dai shi ne karo na farko da abokan ciniki a wasu yankuna na musamman ke tuntuɓar suFarashin CNC, kuma aikin lathes na CNC har yanzu bai iya ƙware dabarun aikin injin ba kawai daga jagorar littafin aiki. Haɗa ƙwarewar aiki da aka tara ta gogayyaKasar China CNCmasu aiki a cikin ayyukansu na yau da kullun, zan yi bayanin basirar saitin kayan aiki da matakan sarrafa wasu sassa.

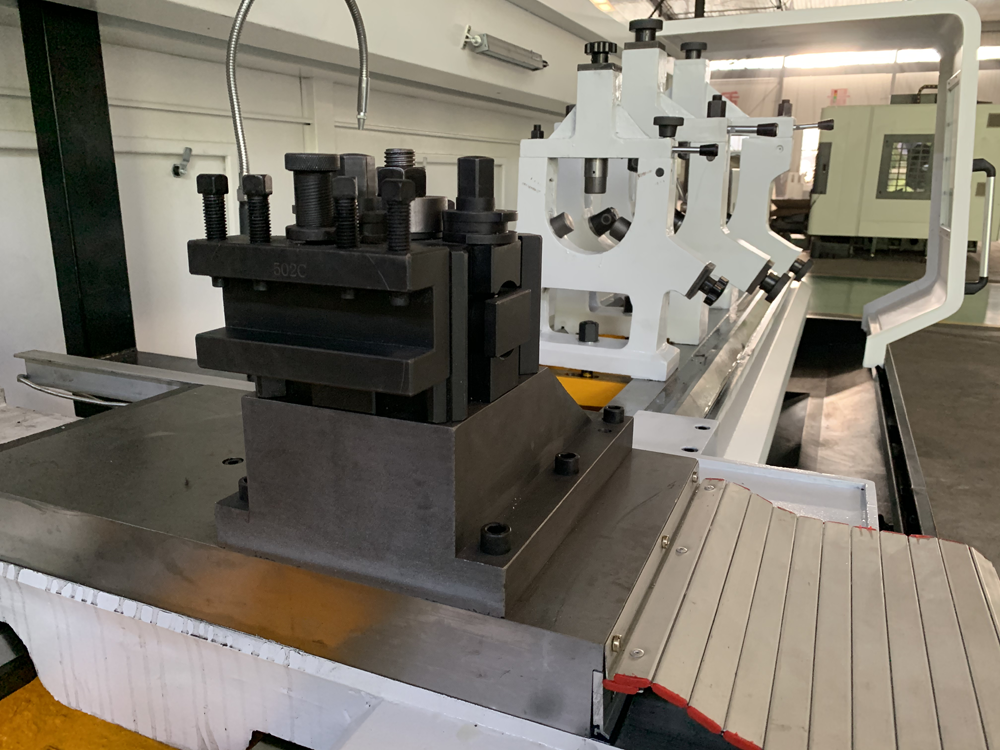

Hanyoyi da basirar saitin kayan aiki a cikin masana'antar kera za a iya raba su zuwa nau'i biyu: saitin kayan aiki kai tsaye da saitin kayan aiki. Kafin lathe CNC ya dawo wurin farawa, kowanejuyowa shimal abin da ake buƙatar amfani da shi an saita shi tare da tsakiyar tsakiyar gefen dama na milling na ɓangaren a matsayin 0, sa'an nan kuma an zaɓi wurin tsakiyar gefen dama na ɓangaren a matsayin 0 da kumaCNC kayan aikian saita batu. Lokacin da kayan aikin juyawa ya taɓa maballin milling na dama, shigar da Z0 kuma danna don ganowa, ƙimar kayan aikin kayan aikin juyawa za ta adana bayanan da aka gano ta atomatik, wanda ke nufin cewa an gama saitin kayan aikin Z-axis, da saitin kayan aikin X. shine saitin kayan aikin gwaji, kuma ana amfani da abin yankan niƙa Ƙa'idar waje na sassan motar ba ta da yawa, kuma bayanan da'irar motar da aka gano (kamar x shine 20 mm) shigar da maballin x20, danna don ganowa, kayan aikin. ƙimar diyya za ta adana bayanan da aka gano ta atomatik, a wannan lokacin kuma an kammala axis x.

Irin wannan hanyar saitin kayan aiki, koda kuwaFarashin CNCya ƙare, ba za a canza ƙimar saitin kayan aiki ba bayan an sake kunna wutar. Ana iya amfani da shi don samar da tsari na dogon lokaci da sarrafa sassa iri ɗaya. A cikin tsawon lokacin, injin baya buƙatar sake daidaitawa lokacin da injin ya rufe.

(1) Da farko ana buga naushi sannan kuma a datse karshen (wannan shi ne don guje wa raguwa yayin bugun naushi).

(2) Juyawa mai kauri da farko, sannan juyi mai kyau (wannan shine don tabbatar da daidaiton sassa).

(3) Da farko a fara aiwatar da wadanda suke da manyan gibi sannan a yi masu kananan gibi (wannan shi ne don tabbatar da cewa ba a tone saman saman karamin gibin da ke waje da kuma kauce wa karkatar da sassan).

(4) Zaɓi madaidaicin rabon gudu, yankan adadin da zurfin yanke bisa ga ka'idodin taurin kayan sa. An zaɓi kayan ƙarfe na ƙarfe na ƙarfe don jujjuyawa mai sauri, babban ƙarfin yankan, da babban zurfin yankan. Kamar: 1Gr11, yi amfani da S1 600, F0.2, da yanke zurfin 2 mm. Alloy yana amfani da ƙarancin saurin gudu, ƙarancin ciyarwa da ƙaramin zurfin yankan. Kamar: GH4033, zaɓi S800, F0.08, kuma yanke zurfin 0.5mm. Titanium alloy karfe yana zaɓar ƙarancin saurin gudu, babban ƙarfin yankan, da ƙaramin zurfin yankan. Kamar: Ti6, yi amfani da S400, F0.2, da yanke zurfin 0.3mm. Ɗauki samar da wani yanki a matsayin misali: kayan shine K414, wanda shine abu mai wuyar gaske. Bayan maimaita gwaje-gwaje, zaɓi na ƙarshe shine S360, F0.1, da zurfin yanke 0.2, kafin a iya samar da daidaitattun sassa. (Wannan don tunani ne kawai, da fatan za a yi gyare-gyare na ainihi bisa ga sigogin injin na kan yanar gizo, kayan aiki, da sauransu don takamaiman yanayi!)

Lokacin aikawa: Nuwamba-29-2021