TheCNC machining centerwani nau'i ne na injin CNC. Hakanan ana rarraba cibiyoyin injin zuwa gidaa kwance machining cibiyoyinkumacibiyoyin injuna na tsaye.

Ƙaƙwalwar igiya (Z-axis) na cibiyar machining na tsaye yana tsaye, wanda ya dace da sarrafa sassan murfin da nau'i daban-daban;

Axis (Z-axis) na cibiyar injinan kwance a kwance. Gabaɗaya, an sanye shi da mujallu na kayan aiki na nau'in sarkar tare da babban iko. Bayan matsewa. Ta atomatik kammala multi-surface, multi-process processing, wanda aka fi amfani da shi don sarrafa sassan akwatin. Na'urar da aka yi amfani da ita don yin aiki na axis biyar yawanci ana kiransa injin axis biyar ko Cibiyar Machining Axis Biyar. Ana amfani da mashin ɗin axis biyar sau da yawa a cikin filin sararin samaniya don sarrafa sassan jiki, sassan injin turbine, da na'urorin motsa jiki tare da saman lanƙwasa daidai. The biyar-axis synchronous CNC inji iya sarrafa daban-daban tarnaƙi na workpiece ba tare da canza matsayi na workpiece a kan inji kayan aiki, wanda zai iya ƙwarai inganta aiki yadda ya dace na prismatic sassa.

CNC machining cibiyoyinana amfani da su a cikin masana'antu masu zuwa:

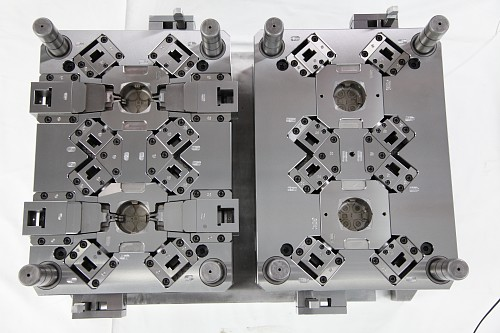

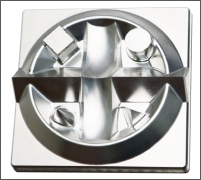

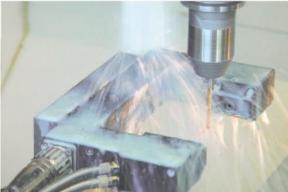

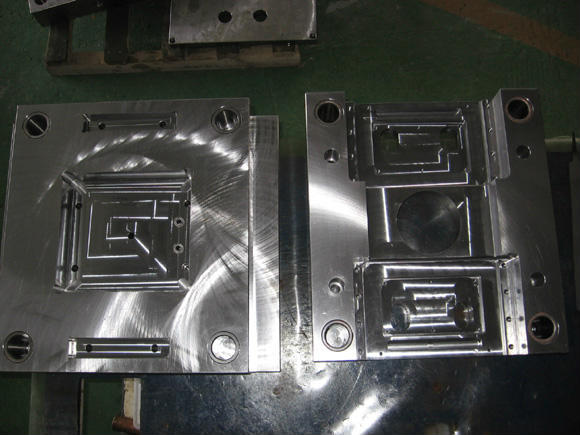

1. Mold

Gabatarwar masana'antar mold:

Ana amfani da gyare-gyare, gyare-gyare daban-daban, da kayan aiki a samar da masana'antu don samun samfuran da ake so ta hanyar yin allura, gyare-gyaren busa, extrusion, mutu-simintin gyare-gyare ko ƙirƙira, narke, stamping, da sauran hanyoyin. A takaice dai, mold kayan aiki ne da ake amfani da shi don yin abubuwa da aka ƙera. Wannan kayan aiki yana kunshe da sassa daban-daban, kuma nau'i-nau'i daban-daban sun hada da sassa daban-daban. Yafi fahimtar sarrafa sifar labarin ta hanyar canjin yanayin jiki na kayan da aka kafa.

Mold

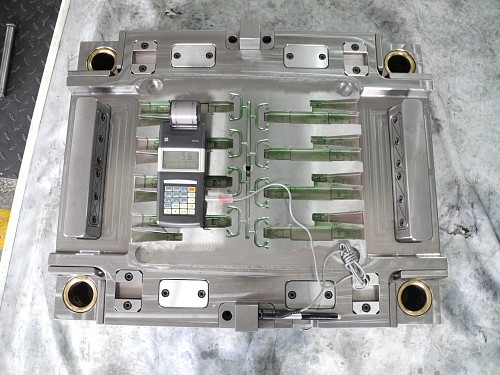

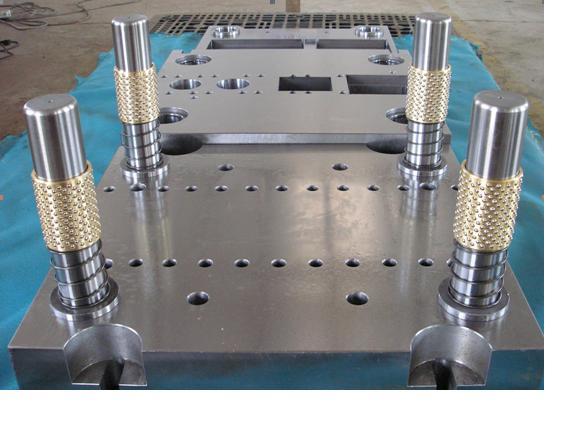

2.Box-dimbin sassa

Sassan da ke da sifofi masu rikitarwa, rami a ciki, babban girma da tsarin rami fiye da ɗaya, da wani yanki na tsayi, faɗi, da tsayin rami na ciki sun dace da su.Injin CNCna machining cibiyoyin.

sassa masu siffar akwati

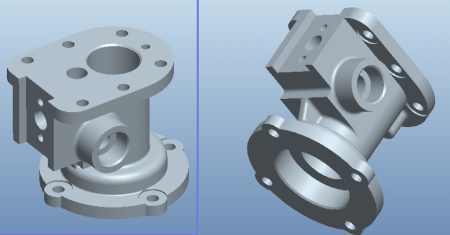

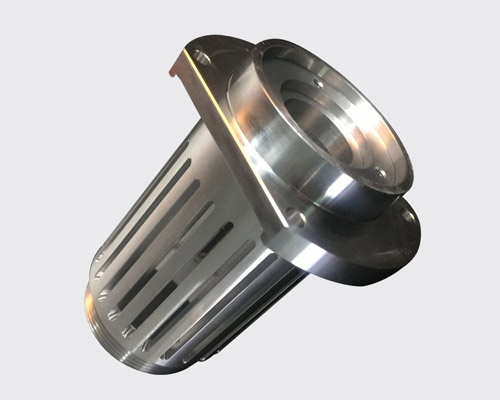

3. Hadadden farfajiya

CNC machining cibiyar za a iya clamped a lokaci guda don kammala aiki na duk gefe da kuma saman saman ban da clamping surface. Ka'idar aiki ta bambanta don samfura daban-daban. Single ko worktable na iya kammala aikin jujjuyawar 90° tare da kayan aikin. Don haka, cibiyar injina ta dace da sarrafa sassan wayar hannu, da na'urorin mota, da kayayyakin sararin samaniya. Kamar murfin bayan wayar hannu, siffar injin da sauransu.

Aerospace sassa

sassa na mota

Injin mirgine CNC mai saurin gudu

Ƙwallon Ƙwallon Ƙwallon Ƙwallon Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwaƙwalwa na Lissafi ) ya yi

3 Axis ball dunƙule da layin jagora dogo sanye take da tsakiyar atomatik lubrication na'urar. 3 Axis dauko madaidaicin ball dunƙule.

3 Axis wanda aka tsara tare da 4 ~ 6 inji mai kwakwalwa masu zamewa tubalan don tabbatar da daidaiton motsi da kwanciyar hankali na injin, tsawaita rayuwar sabis na injin taurin kai.

Tsarin tsari mai tsayi mai tsayi

TheInjin niƙa CNCkayan aikimanyan sassa kamar Injin gado, katako da ginshiƙan an yi su da ƙarfe mai daraja na MEEHANITE. Kuma bayan maganin tsufa da yawa.

yadda ya kamata kawar da ciki danniya, don tabbatar da cewaCNCVMCinjiyana da daidaito mafi kyau.

Kuma bayan maganin tsufa da yawa, yadda ya kamata kawar da damuwa na ciki, don tabbatar da cewa injin yana da daidaito mafi kyau.

Shirye-shiryen dogo na jagorar madaidaiciyar madaidaiciya don katako ( saman saman katako da gaban katako), haɗe tare da ƙirar

da super-fadi sirdi, tabbatar da aiki sakamako na spindle tare da babban madaidaici da babban kwanciyar hankali.

Tsarin Akwatin Spindle na Musamman

Tsarin kai na musamman yana sa motsin z-axis ya zama mafi kwanciyar hankali. Tsarin nauyi mai nauyi ya sa ya yi sauri da sauri a kwance da kuma a tsaye don cimma manufar mayar da martani mai sauri.

Kyakkyawan ƙwarewar mai amfani

Wasua tsayeInjin niƙa CNC zai iya zaɓar cikakken ƙarfen takarda da ke kewaye, don samar wa masu amfani da mafi aminci, muhallin da ke da alaƙa da muhalli. Akwatin aiki mai jujjuyawa da sauran ƙirar ɗan adam suna ba masu amfani dacewa da ƙwarewar aiki mai aminci.

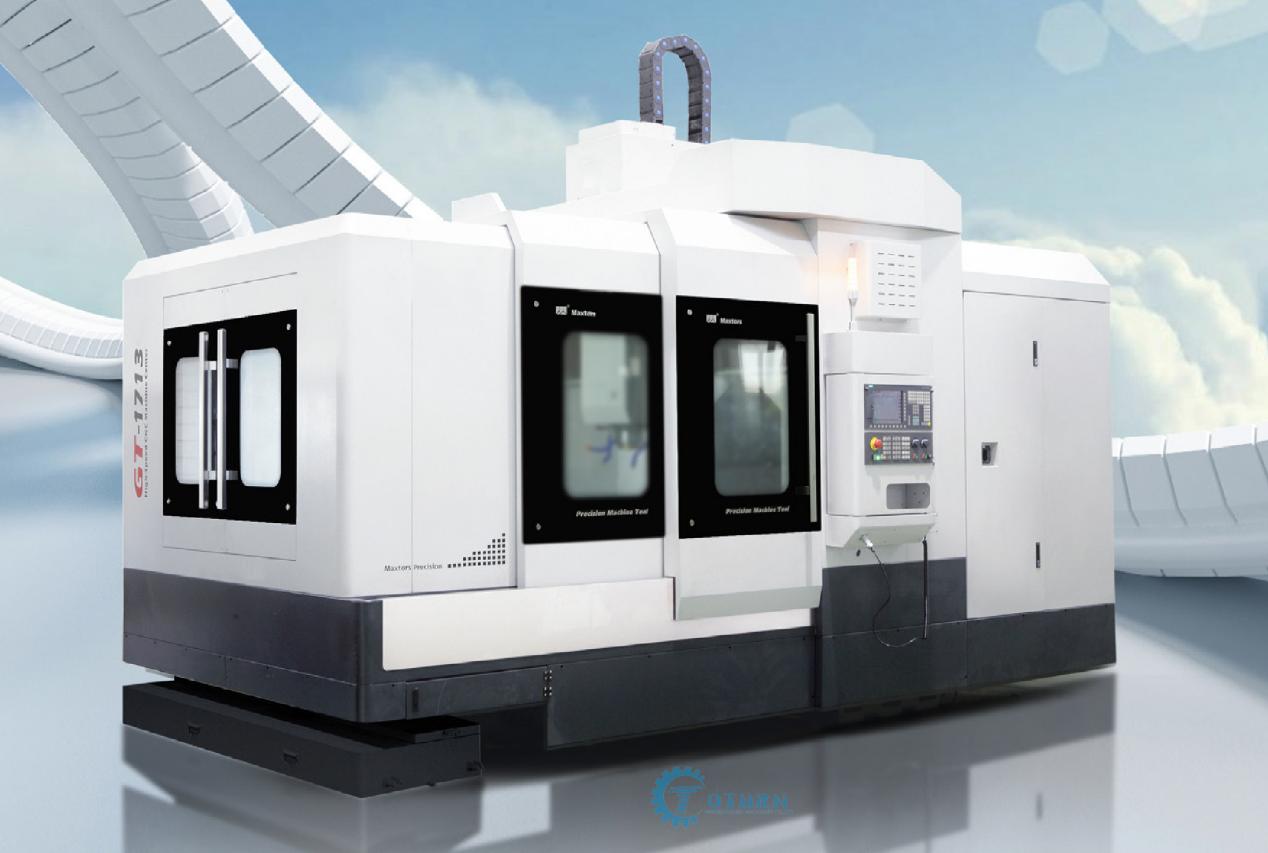

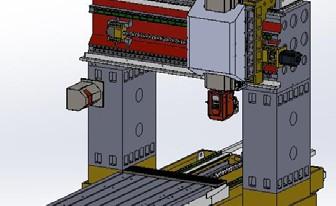

Babban GuduCibiyar Inji

WannanBabban GuduCibiyar InjiTsayawa da ƙarfi mai ƙarfi, daidaiton tsari da kwanciyar hankali mai kyau akan tushen tsarin injin gantry na gargajiya, yana gabatar da ra'ayin ƙirar ƙirar ci gaba mai ƙarfi na ƙasa da haɓaka ƙirar sassa masu motsi.Wannan injin yana da ƙarfi mai ƙarfi da amsa mai sauri, wanda zai iya saduwa da Bukatun sarrafa sassan jirgin sama masu inganci da sarrafa nau'ikan gyare-gyare daban-daban.

3 Madaidaicin axis tare da Sikelin Litattafai, Matsayi mafi daidaito.

Binciken Kayan aikin Laser (Na zaɓi)

Daidaitaccen tare da 21T ATC / Tool Magazine yana iya inganta haɓakar shirye-shiryen mashin ɗin daidai.

3 Axis Roller Guiderails, babban madaidaici da ƙarancin juzu'i, wanda zai iya rage Injin

abin mamaki mai rarrafe a ƙananan gudu, daidaiton matsayi mai kyau da halayen amsa mai ƙarfi mai ƙarfi.

Masu ɗaukar Gina Nau'in Babban Gudun Motoci

Spindle,Max.20000rpm, Mafi kyawun Mahimmanci & Ingantaccen Ingantaccen Tsarin Sama.

ginshiƙai biyu da crossbeam gabaɗayan ɓangaren sa CNC Gantry Milling Machine yana da mafi kyawu, kwanciyar hankali mai dorewa da kyakkyawan aikin ɗaukar girgiza. An sanye shi da babban mai sarrafa aiki, motar servo, babban jagorar jagorar hanya / dunƙule yana sa ya zama babban inganci da daidaito.CNC Gantry Milling Machine. Z axis sanye take da ma'aunin ƙara nitrogen don rage nauyin mota. Don hakaCNC Gantry Milling Machineiya mayar da hankali kan iyawar niƙa. HSK high-gudun sandal na zaɓi ne wanda zai iya inganta aikin niƙa. Gudanar da ilimin kimiyya da tsauraran kayan aikin ganowa suna tabbatar da daidaito da ingancin injin. Ana iya zaɓar mai sarrafa CNC kamar Siemens, Fanuc ko Mitsubishi don cika halayen amfani da abokan ciniki.

Wannan CNC Gantry Milling MachineAna amfani da shi sosai a cikin sassa na atomatik, sararin samaniya, mold, injin, kayan aikin gida da sauran fannoni.

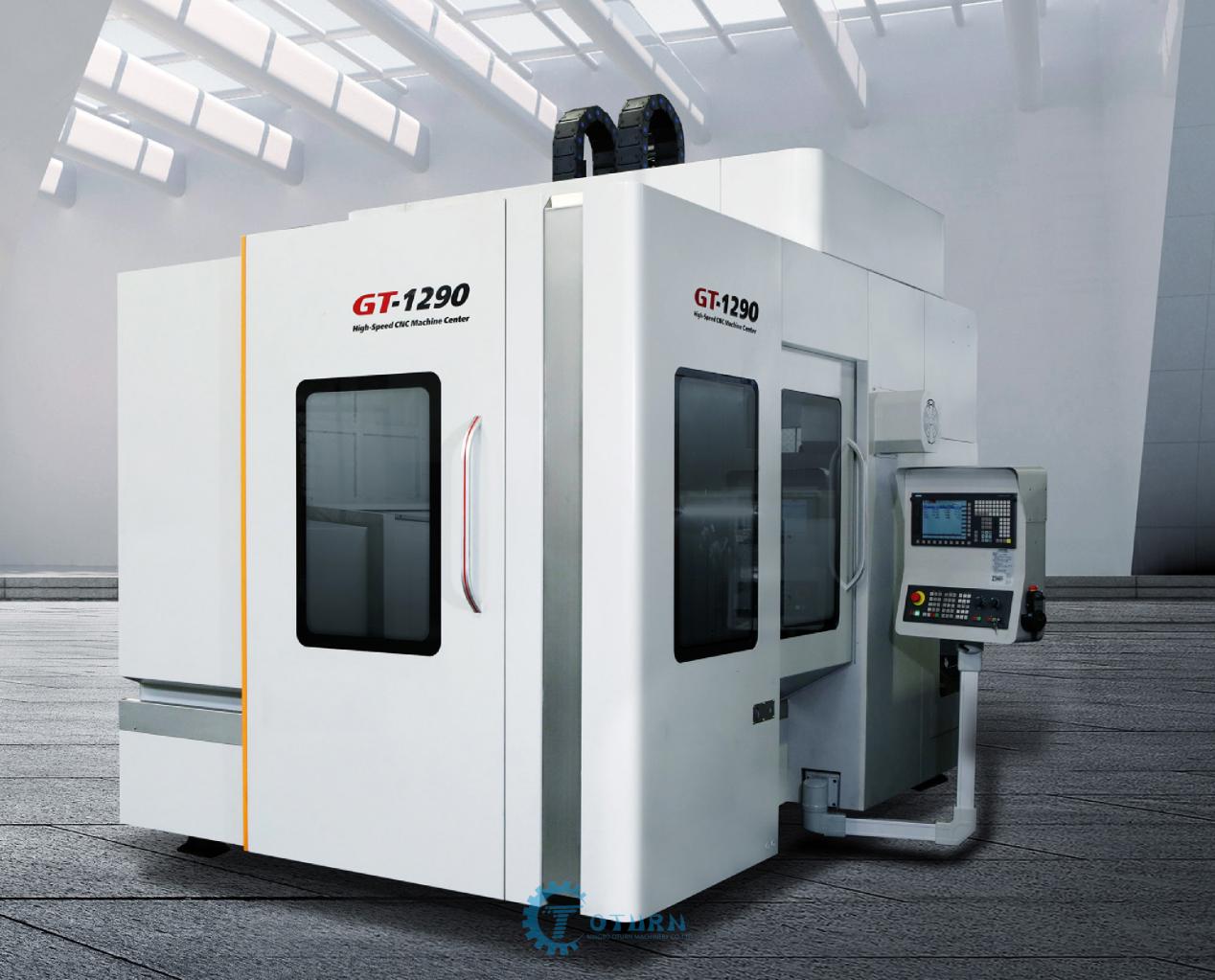

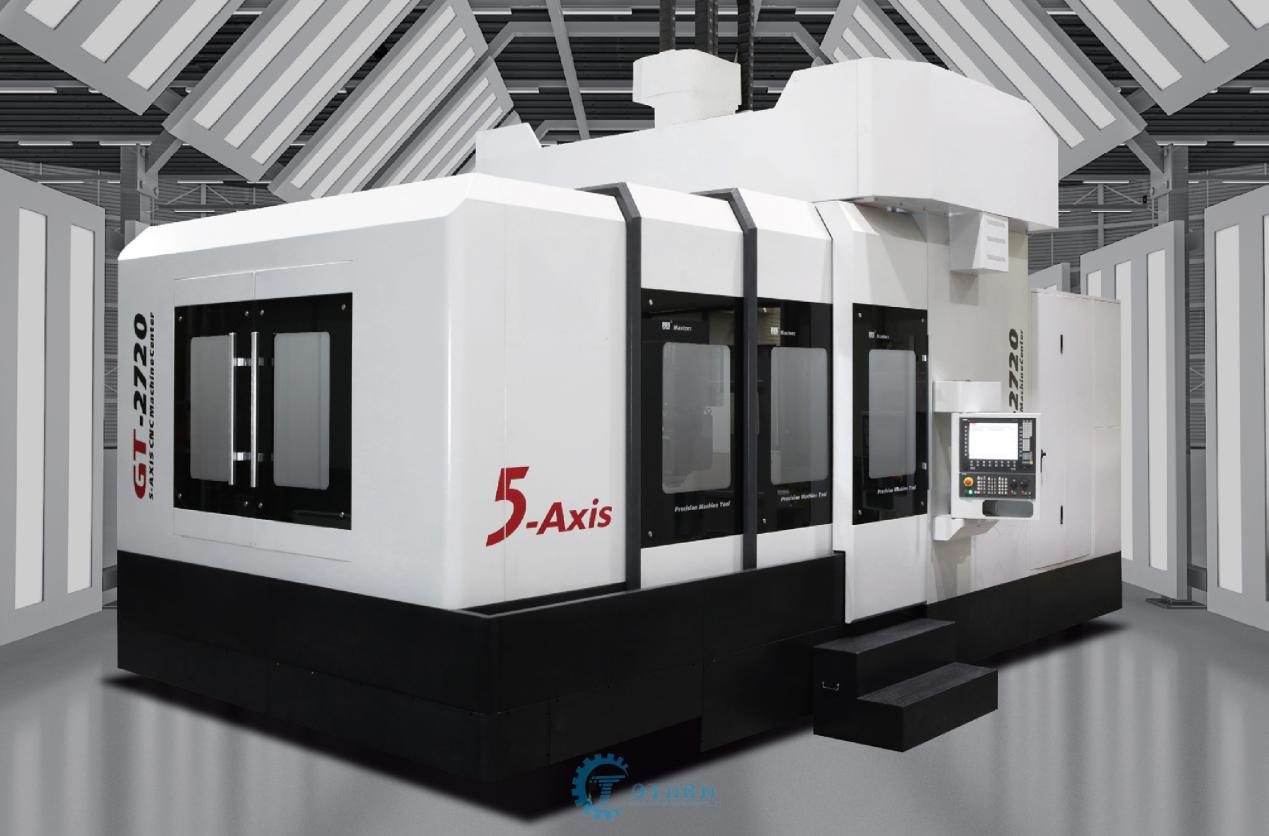

Nau'in Rukuni Biyu5 Cibiyar Injin Axis

Wannan injin Nau'in Rukunna Biyu ne 5 Cibiyar Injin Axis, Tsayawa da ƙarfi mai ƙarfi, tsarin daidaitawa da kwanciyar hankali mai kyau akan tushen tsarin gantry na'ura na gargajiya, yana gabatar da ra'ayin ƙira mai ƙarfi na ƙasa da ƙasa da haɓaka ƙirar sassa masu motsi.Wannan injin yana da ƙarfi mai ƙarfi da amsa mai sauri, wanda zai iya saduwa Bukatun sarrafa kayan aikin jirgin sama masu inganci da nau'ikan sarrafa gyare-gyare daban-daban.

A nesa daga Spindle Center to shiryar da dogo surface ne short.with Good Structure Rigidity Beam, yadda ya kamata inganta motsi kwanciyar hankali na spindle.Z - axis da guda 4 guda guderails zane tsarin, Overall tsarin rigidity muhimmanci inganta.

Dauki high-gudun Gina-in sandal, max 20000RPM, wanda zai iya samar da cikakken bayani ga high ainihin machining da high surface ingancin machining.

3 Madaidaicin axis tare da Sikelin Litattafai, Matsayi mafi daidaito.

Thea tsaye da a kwanceCNC machining centerwata muhimmiyar hanyar haɗi ce a matakin fasaha na dukan masana'antu. A cikin 'yan shekarun nan, abokan ciniki a kasuwannin duniya sun canza ra'ayinsu game da cibiyoyin kera na kasar Sin. Matsayin taro, daidaito da kwanciyar hankali na cibiyar mashin ɗin, da ƙirar bayyanar an inganta su sosai, kuma an riga an kwatanta da samfuran Taiwan, Japan da Koriya ta Kudu. Haɗe tare da ƙayyadaddun ƙayyadaddun kasuwar kasar Sin, farashin masana'antu da samar da kayayyaki sun yi ƙasa da na Taiwan, Japan da Koriya ta Kudu, wanda hakan ya sacibiyar sarrafawaabokan ciniki sun amince da su a kasuwannin Turai da Amurka kowace shekara, wanda kuma ke nuna ci gaban cikakken karfin tattalin arzikin kasar Sin.

Duk da haka, har yanzu muna da wani tazara tsakanin mumafi girma-daidaici CNC machining cibiyoyinda injuna a kasuwannin Turai da Amurka, da ma wasu na'urorin haɗi da fasahohin mu har yanzu suna buƙatar shigo da su. Thecibiyoyin injina wasu kasashen da suka ci gaba sun riga sun cimma daidaito mai inganci, saurin gudu, hada-hadar ayyuka da yawa, hada-hadar axis da sauran ayyuka. Wadannan su ne wuraren da har yanzu akwai gibi tsakanin Sin da kasashen da suka ci gaba a Turai da Amurka. Ci gaban cibiyar sarrafa injinan axis biyar na kasar Sin har yanzu yana da iyakancewa ta hanyar tsarin kula da lambobi na kasashen waje, don haka ayyuka da matakin fasaha na wasu manyan fasahohin zamani ba za su iya cika ka'idojin da ake bukata ba, wanda ya sa wasu kayayyaki da muhimman abubuwan da suka dace dole ne su dogara da shigo da su daga waje. . Saboda haka, mun ga cewa wasuSin CNC machining cibiyar masana'antutsire-tsire ne don samun sararin kasuwa mai yawa a matakin kasa da kasa, kuma sun tashi tsaye don yin wasu sauye-sauye. Wannan shi ne manufar tsarar Sinawa.

A halin yanzu, ƙungiyoyin abokan cinikinmu sun haɗa da ginin jirgi, masana'antar yadi, masana'antar kera motoci, masana'antar sararin samaniya, da sauransu. Akwai buƙatu masu tsauri akan daidaita mashin ɗin. Misali, ana buƙatar saurin igiya ya kasance sama da 12000rpm/min, kuma saurin motsi yana sama da 40m/min. Don hadaddun workpieces, musamman masu lankwasa saman tare da hadaddun siffofi, suna da babban buƙatu don daidaito da inganci. Machining Multi-axis dole ne ya zama zaɓin da aka fi so, kamar ƙananan 5-axis 5-linkage machining centers da manyan.5-axis gantry machining centers.

Tare da sannu-sannu aiwatar da sarrafa kansa na masana'antu, an yi amfani da cibiyoyin injina da na'urorin masana'antu a hade, ba da damar robots su ɗauki wasu ayyuka masu sauƙi da maimaitawa, wanda zai iya ceton farashin samarwa da yawa. Haɗe tare da kwanciyar hankali na mutum-mutumi da cibiyar injina, ana kuma tabbatar da ingancin samfurin.

Ci gaban cibiyar mashin ɗin na wannan shekara yana da matuƙar tasiri ga rashin iya samar da tsarin CNC a kan kari. A halin yanzu, tsarin CNC da aka sanye a cibiyoyin kera na kasar Sin kusan dukkan nau'ikan nau'ikan kayayyaki ne na kasashen waje, kamar FANUC, MITSUBISHI, SIEMENS. Kuma samfuran Taiwan na ƙasata Syntec, samfuran gida na LNC GSK, KDN Ko da yake Huadong CNC da dai sauransu na iya gane ayyukan sanannun samfuran ƙasashen waje, har yanzu akwai wasu ayyuka marasa ƙarfi waɗanda ba za a iya maye gurbinsu ba.

A matsayin haɗewar filin haɓaka masana'antu da fasaha,cibiyar sarrafawaHakanan ya nuna matakin ci gaban kasar. Yayin da kasar Sin ke kara zama mai muhimmanci a fagen kasa da kasa, akwai bukatar robots na kasar Sin su yi aiki tare don inganta matsayin kasar Sin baki daya.

Lokacin aikawa: Satumba 18-2021