Injin lathe na al'adanau'in injin lathe na gargajiya ne ba tare da sarrafawa ba amma na hannu. Yana da faɗin yankan kewayon kuma yana iya sarrafa ramukan ciki, da'irori na waje, fuskokin ƙarewa, filaye masu ɗigo, chamfering, tsagi, zaren zare da saman baka daban-daban. Nau'in lathes na al'ada sune nau'in injunan lathe da aka fi amfani da su, wanda ya kai kusan kashi 65% na adadin na'urar lathe. Ana kiran su da lathes a kwance saboda an ajiye su a kwance.

Ayyuka:

1. Juyin Silinda na waje, jujjuya mazugi, jujjuyawar ƙasa mai lankwasa, jujjuyawar rami na ciki, juyawar ƙarshen fuska, chamfering da sauran machining;

2. Zaren ma'auni, zaren inch, zaren zamani, yankan zaren farar;

3. Shot da dogon taper juya;

4. Drilling, m, jacking da tsagi;

5. Juya hannun hagu da juyar da hannun dama;

6. Ko da nika da niƙa tare da niƙa da niƙa abin da aka makala.

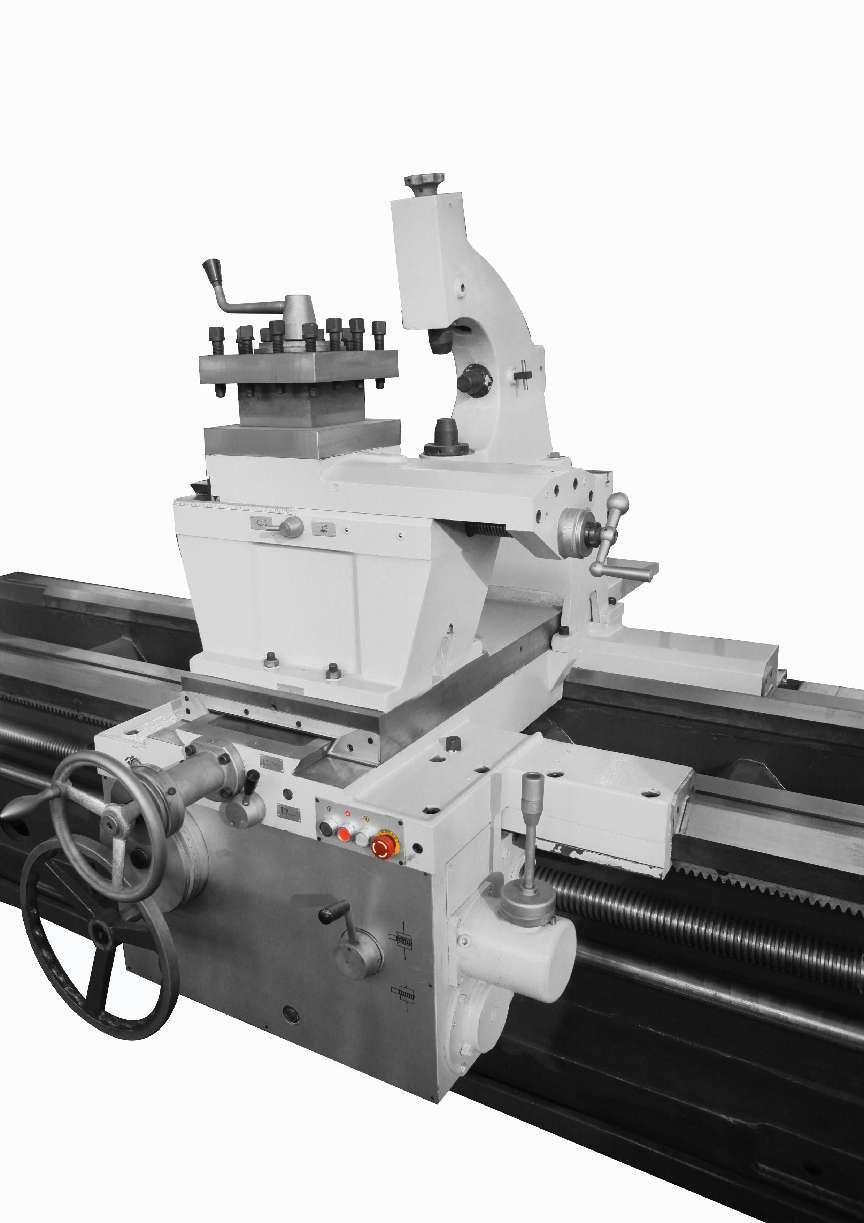

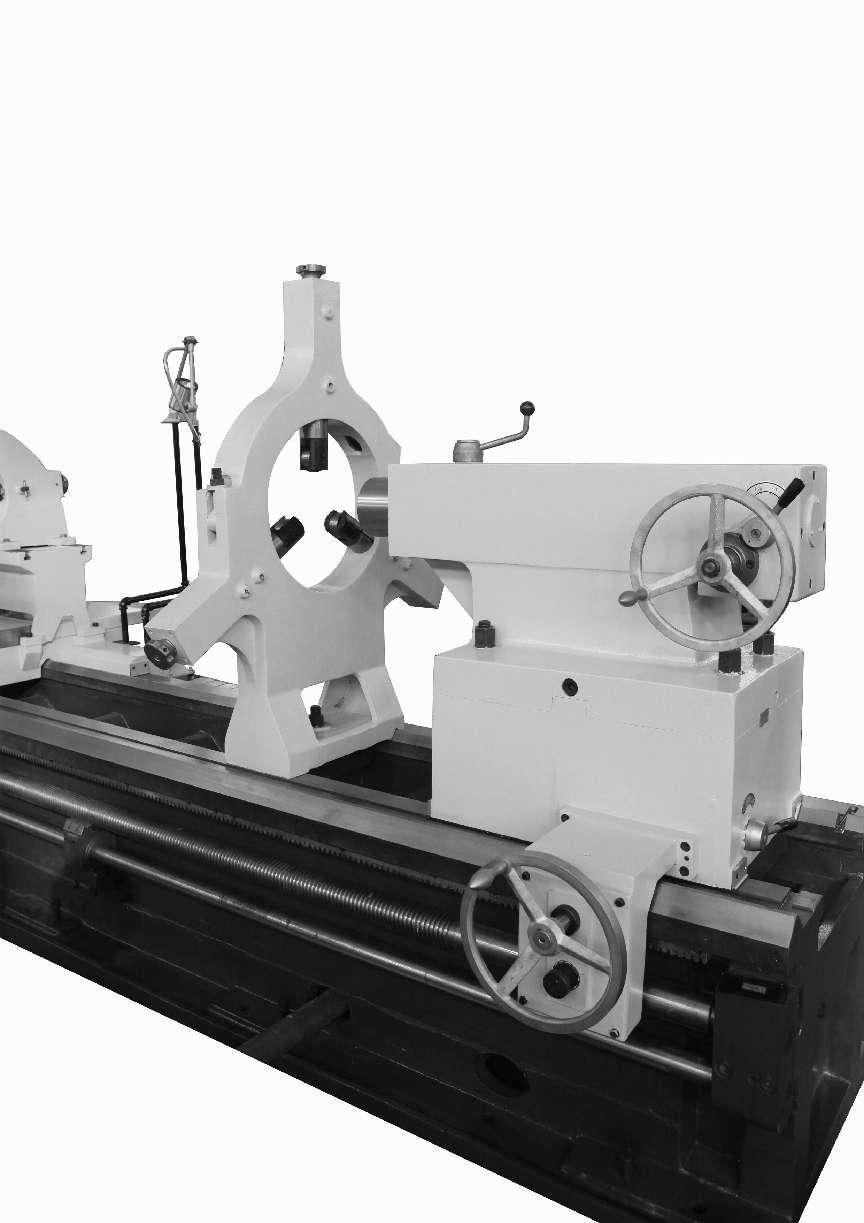

Babban sassan nainji na al'ada: gado, headstock, feed akwatin, kayan aiki post, karusa, wutsiya, da kuma mota.

Kwanciya: Babban sassaninjin lathean shigar da su a kan gado, don su kula da daidaitaccen matsayi na dangi a yayin aiki. Karusar da kayan hawan wutsiya suna zamewa a kan shimfidar gado mai kyau.

Kayan kai: An cire kai a kan gado kuma yana riƙe duk hanyoyin, gami da nau'ikan ɗakunan da ke jujjuyawa ta hanyar babban abin maye gurbin naúrar saboda babban shaft na iya samun saurin gudu daban-daban da ake buƙata na gaba da jujjuyawar baya, kuma a lokaci guda, ƙwanƙarar ta raba wani ɓangare na ikon watsa motsi zuwa akwatin abinci. Headstock Medium spindle wani maɓalli ne na lathe. Gudun kan ɗaukar nauyi kai tsaye yana rinjayar ingancin aiki na kayan aikin. Da zarar an rage daidaiton juyawa na sandal, ƙimar amfani nakayan aikin injinza a rage.

Akwatin ciyarwa: Akwatin ciyarwa yana sanye take da tsarin canjin saurin don ciyar da motsi. Daidaita hanyar canza saurin gudu don samun adadin abincin da ake buƙata ko farar da ake buƙata, da kuma watsa motsi zuwa mai riƙe da kayan aiki ta hanyar dunƙule mai santsi ko jagora don yankewa.An yi amfani da dunƙule gubar musamman don juya zaren daban-daban. Lokacin juya sauran saman kayan aikin, kawai dunƙule mai santsi ana amfani da shi maimakon dunƙule gubar.

Mai riƙe kayan aiki: Mai riƙe kayan aiki ya ƙunshi yadudduka da yawa na posts kayan aiki. Ayyukansa shine matsa kayan aiki da sanya kayan aiki ya motsa a tsaye, a gefe ko a bayyane.

Tailstock: A matsayin cibiyar baya don sakawa goyon baya, ana iya shigar da shi tare da kayan aikin ramuka irin su drills da reamers don sarrafa rami.

sassa

Shuck-jaw uku (don kayan aikin cylindrical)

hudu-jaw chuck (don aikin da ba daidai ba)

hali

Kayan aikin inji na al'adasuna da tsari mai sauƙi, aiki mai sauƙi, babban diamita na spindle, ƙananan sawun ƙafa, babban sassaucin sarrafawa, sauƙi mai sauƙi, dace da ƙananan sarrafa tsari da babban farashi.

Kwancen gadon yana ɗaukar gado mai mahimmanci tare da tsayi mai tsayi. Injin yana sanye da famfo mai daban. Zamewar, mariƙin kayan aiki, da sirdi na iya motsawa da sauri. Wannan kayan aikin injin na iya ɗaukar tsarin GSK ko SIEMENS na zaɓi, FANUC tsarin kula da lambobi da sauran tsarin kula da lambobi bisa ga buƙatun mai amfani, wanda zai iya aiwatar da babban sauri, ƙarfi da kwanciyar hankali, ingantaccen machining daidaito da shirye-shirye masu sauƙi.

Thea tsaye da a kwanceciyarwar tana ɗaukar motar AC servo, kuma ana amfani da ra'ayoyin encoder na bugun jini azaman ɓangaren amsawa. A tsaye da a kwance motsi jagora dogo suna hõre ultrasonic hardening da lafiya nika magani. Ana liƙa titin jagorar gado tare da tef mai laushi na PTFE, kuma ƙimar juzu'i kaɗan ce.

Babban motar yana ɗaukar yanayin ƙa'idar saurin gauraya na ƙa'idar maganadisu da ka'idar ƙarfin lantarki, don yin ƙa'idar saurin gudu mara ƙarfi.

Hanyoyin aiki

1. Dubawa kafin farawa

1.1 Ƙara man shafawa mai dacewa bisa ga ginshiƙi na mashin.

1.2 Bincika duk wuraren lantarki, rikewa, sassan watsawa, karewa da na'urori masu iyaka sun cika, abin dogaro da sassauƙa.

1.3 Kowane kaya ya kamata ya kasance a matsayi na sifili, kuma bel ɗin ya kamata ya dace da bukatun.

1.4 Ba a yarda a adana kayan ƙarfe kai tsaye a kan gado ba, don kada ya lalata gado.

1.5 Kayan aikin da za a sarrafa ba shi da laka da yashi, yana hana laka da yashi fadawa cikin injin da kuma lalata hanyar dogo.

1.6 Kafin aikin da aka ƙulla, dole ne a gudanar da aikin gwajin motar fanko, kuma za'a iya ɗaukar kayan aikin kawai bayan tabbatar da cewa komai na al'ada ne.

2. Hanyar aiki

2.1 Bayan an shigar da kayan aikin, fara famfo mai mai mai da farko don sanya matsin mai ya dace da kayan aikin injin kafin farawa.

2.2 Lokacin daidaita ma'aunin kayan aikin musayar, lokacin daidaita dabaran rataye, dole ne a yanke wutar lantarki. Bayan daidaitawa, dole ne a ɗaure dukkan kusoshi, a cire maƙarƙashiya a cikin lokaci, kuma ya kamata a cire haɗin aikin don aikin gwaji.

2.3 Bayan lodawa da sauke kayan aikin, chuck wrench da iyo sassa na workpiece ya kamata a cire nan da nan.

2.4 Za a daidaita kayan aikin injin wutsiya, ƙugiya, da dai sauransu zuwa wurare masu dacewa bisa ga buƙatun sarrafawa, kuma za a ɗaure ko ɗaure.

2.5 Kayan aiki, kayan aiki da kayan aiki dole ne a ɗora su cikin aminci. Dole ne kayan aikin ƙarfi mai iyo dole ya shimfiɗa ɓangaren jagora zuwa cikin kayan aiki kafin fara kayan aikin injin.

2.6 Lokacin amfani da hutun cibiyar ko sauran kayan aiki, dole ne a daidaita cibiyar da kyau, kuma dole ne a sami lubrication mai kyau da wuraren tallatawa.

2.7 Lokacin sarrafa dogayen kayan aiki, ɓangaren da ke fitowa a bayan babban shaft bai kamata ya yi tsayi da yawa ba.

2.8 Lokacin ciyar da wuka, wuka ya kamata ya kusanci aikin a hankali don guje wa karo; gudun abin hawa ya zama uniform. Lokacin canza kayan aiki, kayan aiki da kayan aiki dole ne a kiyaye su a nesa mai dacewa.

2.9 Dole ne a ƙarfafa kayan aikin yankan, kuma tsayin tsayin kayan aikin juyawa gabaɗaya bai wuce sau 2.5 na kauri na kayan aiki ba.

2.1.0 Lokacin da ake sarrafa sassan eccentric, dole ne a sami madaidaicin kiba don daidaita tsakiyar nauyi na chuck, kuma saurin abin hawa yakamata ya dace.

2.1.1. Dole ne a sami matakan kariya don kayan aikin da chuck ɗinsa ya wuce fuselage.

2.1.2 Daidaita saitin kayan aiki dole ne ya kasance a hankali. Lokacin da tip ɗin kayan aiki ya kasance 40-60 mm nesa da ɓangaren sarrafa kayan aikin, yakamata a yi amfani da jagora ko abinci mai aiki a maimakon haka, kuma ba a yarda da saurin ciyarwa kai tsaye shigar da kayan aikin ba.

2.1.3 Lokacin goge kayan aikin tare da fayil, mariƙin kayan aiki yakamata a dawo da shi zuwa wuri mai aminci, kuma mai aiki yakamata ya fuskanci chuck, tare da hannun dama a gaba da hannun hagu a baya. Akwai hanya mai maɓalli a saman, kuma an hana amfani da fayil don sarrafa kayan aikin da rami murabba'i.

2.1.4 Lokacin polishing da'irar waje na workpiece tare da Emery zane, mai aiki ya kamata ya riƙe iyakar biyu na Emery zane tare da hannaye biyu don goge bisa ga matsayi da aka ƙayyade a cikin labarin da ya gabata. An haramta amfani da yatsunsu don riƙe mayafin da zai goge rami na ciki.

2.1.5 A lokacin ciyar da wuka ta atomatik, ƙaramar mariƙin wuƙa ya kamata a daidaita shi don a haɗa shi da tushe don hana tushe daga taɓa chuck.

2.1.6 Lokacin yankan manyan kayan aiki ko kayan aiki masu nauyi, isassun izinin injin ya kamata a tanadi.

3. Yin kiliya

3.1 Yanke wutar lantarki kuma cire kayan aikin.

3.2 Hannun kowane bangare suna rushewa zuwa matsayi na sifili, kuma ana ƙidaya kayan aikin da tsaftacewa.

3.3 Duba yanayin kowace na'urar kariya.

4. Kariya yayin aiki

4.1 An haramta shi sosai ga waɗanda ba ma'aikata ba suyi aiki da injin.

4.2 An haramta shi sosai don taɓa kayan aiki, ɓangaren jujjuyawar kayan aikin injin ko kayan aikin juyawa yayin aiki.

4.3 Ba a yarda a yi amfani da tasha na gaggawa ba. A cikin yanayin gaggawa, bayan amfani da wannan maɓallin don tsayawa, yakamata a sake duba shi bisa ga ƙa'idodi kafin fara kayan aikin injin.

4.4 Ba a yarda a taka saman layin dogo na jagora, sandar dunƙulewa, sanda mai goge baki, da sauransu na lathe. Sai dai ga ƙa'idodi, ba a ba da izinin yin aiki da hannu tare da ƙafafu maimakon hannu ba.

4.5 Don sassan da blisters, ramukan raguwa ko maɓalli a bangon ciki, ba a ba da izinin scrapers na triangular su yanke ramukan ciki ba.

4.6 Matsakaicin iska ko matsa lamba na ruwa na pneumatic rear hydraulic chuck dole ne ya kai ƙayyadadden ƙimar kafin a iya amfani da shi.

4.7 Lokacin da juya siriri workpieces, a lokacin da protruding tsawon gaban biyu na kan gadon ya fi 4 sau diamita, ya kamata a yi amfani da cibiyar bisa ga tsari dokokin. Taimakon hutun tsakiya ko hutun diddige. Ya kamata a ƙara masu tsaro da alamun gargaɗi lokacin da suke fitowa a bayan kan gadon.

4.8 Lokacin da ake yanke karafa ko yankan sauƙi a fantsama (ciki har da niƙa), ya kamata a ƙara baffles masu kariya, kuma masu aiki su sa gilashin kariya.

sauran

Tare da shahararsa naInjin CNC,ƙarin kayan aiki na atomatik suna fitowa a kasuwa.Lathes na gargajiyasuna da nasu fa'idodin da ba za a iya musanya su ba kuma har yanzu sune injunan da ake buƙata don yawancin masana'antar sarrafa su.

1. Kayan aikin inji na al'adasun fi araha

Farashin siyanFarashin CNCsau da yawa ya fi tsada fiye da na al'ada lathe da irin wannan iko, da kuma daga baya goyon baya, gyara, goyon bayan consumables da sauran halin kaka su ma sun fi shi yawa.

2.More dace da ƙananan mashina

Lokacin da ƙananan batches na workpieces kawai ke buƙatar yin machining,mafi yawan ƙwararrun ma'aikata na iya yin injin sashi tare da kayan aikin injin na yau da kullun tare da zanen sassa.

3.High albashi na CNC shirye-shirye da 'yan baiwa

Masu shirye-shiryen CNC galibi suna buƙatar ƙarin albashi, kuma akwai nau'ikan tsarin CNC da yawa. Babu shakka yana da wahala a sami ma'aikacin da ya kware a cikiKayan aikin injin CNCfiye da ma'aikacin kayan aikin injin na al'ada.

4.Game da kuɗin shigar kasuwanci

Idan aka yi la'akari da babban juzu'i na masana'antu da kuma amfani da kayan aiki masu ma'ana, kamfanoni da yawa suna ci gaba da samarwa ta hanyarna'ura na al'adakayan aiki.

Gabaɗaya, kodayake masana'antar CNC ta zama babban ci gaba a cikin haɓaka masana'antar masana'anta, kayan aikin injin na yau da kullun suna da fa'idodin nasu na musamman game da haɓaka kayan aikin fasaha. Tare da ci gaba da inganta hankali naKayan aikin injin CNCa nan gaba, ana iya maye gurbin kayan aikin inji na gargajiya a kan babban sikelin, amma ba zai yiwu a kawar da su gaba ɗaya ba.

| MISALI | CW61(2)63E | CW61(2)80E | CW61(2)100E | CW61(2)120E | CWA61100 |

| WUTA | |||||

| Max.juya bisa gado | mm 630 | 800mm | 1000mm | 1200mm | 1000mm |

| Max.swing over giciye slide | mm 350 | mm 485 | mm 685 | 800mm | mm 620 |

| Matsakaicin tsayin juyawa | 750,1250,1750,2750,3750,4750,5750,7750,9750,11750mm | 1.5m 2m 3m 4m 5m 6m 8m 10m 12m | |||

| Max.juya sama da gibi | mm830 ku | 1000mm | 1200mm | 1400mm | mm 780 |

| Ingantacciyar tsayin rata | 230m | 8T | |||

| Fadin gado | mm 550 | ||||

| KANSA-KASA | Φ130mm | ||||

| Ramin Spin | 105mm KO 130mm (ZABI NA CW6180E+) | Ma'auni140# | |||

| Leda hanci | D-11 ya da C-11 | 3.15-315r/min ko 2.5-250r/min | |||

| Spindle taper | Φ120mm taper1:20(Φ140, ZABI NA CW6180+) | Gaba 21iri,Juyawa12iri | |||

| Gudun Spindle (Lambar) | 14-750RPM(18 matakai) | ||||

| KWALLON GEAR-ZURU & CIKI | 44nau'in 1-120mm | ||||

| Kewayon zaren awo (iri) | 1-240mm (iri 54) | 31 iri 1/4-24 T/I | |||

| Zaren Inci (Iri) | 28-1 inch (iri 36) | 45iri 0.5-60 mm | |||

| Kewayon zaren moudle (iri) | 0.5-60 DP (iri 27) | 38irin 1/2-56DP | |||

| Kewayon zaren diamitaral(iri) | 30-1 tpi (iri 27) | 56 nau'in 0.1-12mm | |||

| Matsakaicin ciyarwa (iri) | 0.048-24.3mm/r (72 iri) | 56iri 0.05-6 mm | |||

| Kewayon ciyarwa (iri) | 0.024-12.15mm/r (72 iri) | 3400mm/min,1700mm/min | |||

| Ciyarwar gaggawa: Doguwa./Cross | 4/2m/min | ||||

| Girman jagoran jagora: Diamita/Pitch | T48mm/12mm KO T55mm/12mm (na 5M+) | 48mm ku | |||

| KARO | 45*45mm | ||||

| Ketare tafiya ta zamewa | mm 350 | mm 420 | mm 520 | ||

| Hadarin hutu tafiya | 200mm | mm 650 | |||

| Girman kayan aiki shank | 32*32mm | mm 280 | |||

| TAILSTOCK | |||||

| Diamita na Spindle | 100mm | 120mm | Φmm 160 | ||

| Spindle taper | MAFITA #6 | Ma'auni 80# | |||

| Tafiyar spinle | mm 240 | 300mm | |||

| MOTOR | |||||

| Babban motar tuƙi | 11 kw | 22 kw | |||

| Coolant famfo motor | 0.09kw | 0.15kw | |||

| Motar ciyar da sauri | 1.1kw | 1.5kw | |||

Lokacin aikawa: Afrilu-14-2022