Hakanan ana kiran lathe ɗin zaren bututuman kasar latheJuya zaren gabaɗaya yana nufin hanyar machining zaren a kan wani workpiece tare da kafa kayan aiki, yafi ciki har da juya, milling, tapping, threading nika, nika, da guguwa yanke. Lokacin juyawa, niƙa da zaren niƙa, sarkar watsawa na kayan aikin injin yana tabbatar da cewa kayan aikin juyawa, mai yankan niƙa ko dabaran niƙa suna motsawa daidai kuma a ko'ina tare da axis na aikin ta hanyar jagora ɗaya don kowane juyi na workpiece. Lokacin dannawa ko zaren, kayan aikin (matsa ko mutu) yana juyawa dangi zuwa kayan aikin, kuma tsagi na farko da aka kafa yana jagorantar kayan aiki (ko workpiece) don motsawa axially.

Kuma abin da muka fi mayar da hankali a kai shi ne amfani da zaren juyawabututu zaren lathes. Za a iya amfani da kayan aiki da zaren kafa kayan aiki ko kayan zaren tsefe don kunna zaren a kan latsewar zaren. Juya zaren tare da samar da kayan aikin juyawa, tsarin kayan aiki mai jinkirin yana da sauƙi, hanya ce ta gama gari don samar da ƙaramin tsari da sarrafa kayan aikin da aka haɗa. Juya zaren tare da zaren tsefe kayan aiki yana da babban samarwa yadda ya dace, amma tsarin kayan aiki yana da rikitarwa, kuma yana dacewa da jujjuya lallausan haƙora gajeriyar zaren workpieces a matsakaici da manyan samarwa.

Daidaiton farar lathes na yau da kullun don juya zaren trapezoidal na iya kaiwa 8-9 kawai, amma ingancin samarwa da daidaiton ƙwararru.CNC bututu threading injiza a inganta sosai.

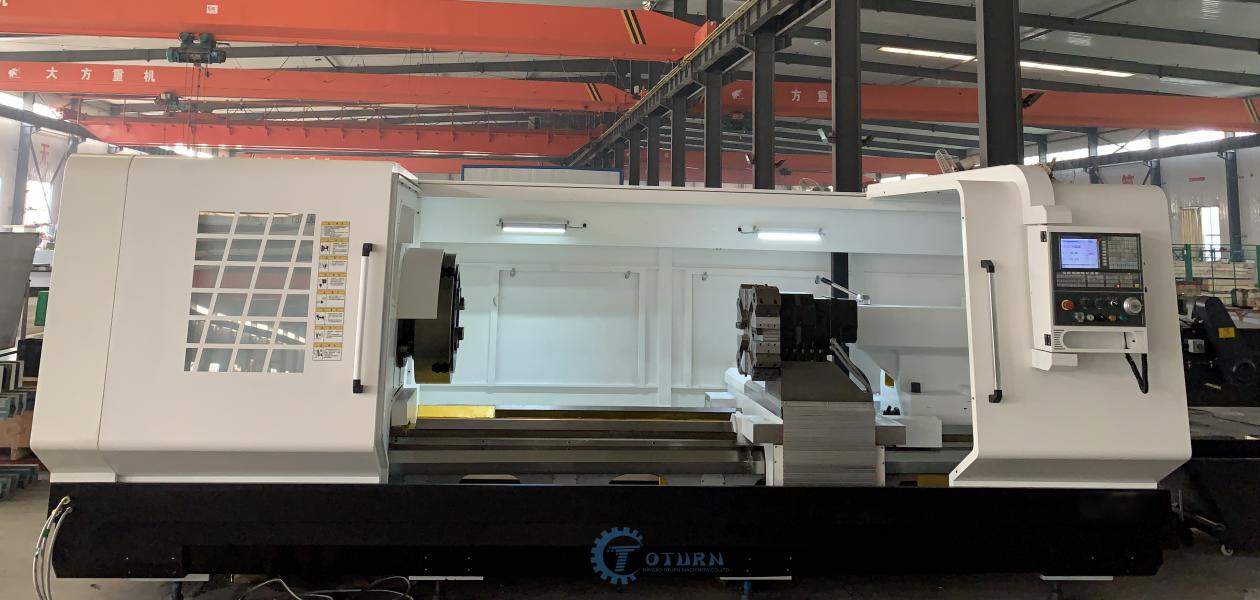

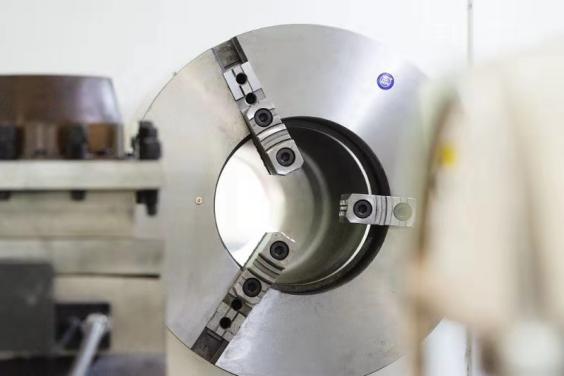

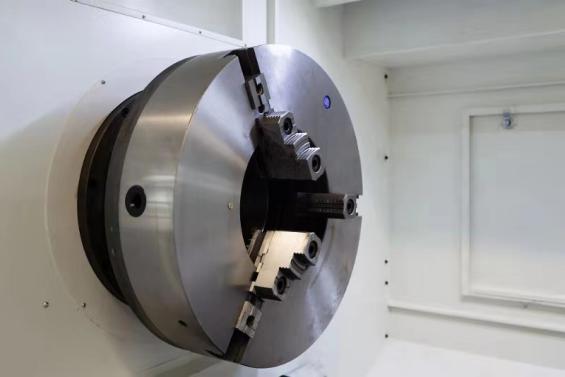

Bututu zaren latheinjiLathe ne a kwance wanda aka kera musamman don jujjuya kayan aikin bututu mai girman diamita. Ana siffanta shi da wani ɗan ƙaramin diamita mai girma ta rami na sandal (gaba ɗaya sama da 135mm) da ƙugiya a gaba da bayan akwatin sandal. , Don sauƙaƙe damfara da sarrafa manyan bututu ko sanduna.

Kasar mailatsainjiGabaɗaya suna da babban rami-rami akan akwatin sandal, kuma aikin yana manne ta chucks biyu a ƙarshen mashin ɗin don juyawa bayan wucewa ta ramin. Gabaɗaya akwai hanyoyi guda biyu don ciyar da kayan aiki: ɗaya daidai yake da lathe na yau da kullun ta hanyar dunƙule gubar don fitar da zamewar da mariƙin kayan aiki a gaban gadon; ɗayan shine lebur tsefe akan zamewar dake tsakiyar gadon. Shugaban yankan zaren waje na wuka (duba kai tsaye buɗewa da rufe zaren yanke kai) ya yanke cikin workpiece kuma yana motsawa gaba. Wasu kayan aikin injin don sarrafa dogayen bututu kuma suna da na'urorin tallafi na aiki, kamar firam ɗin tsakiya, sauran kayan aiki, da madaidaicin baya.

CNC bututu threading lathebayar da shawarar

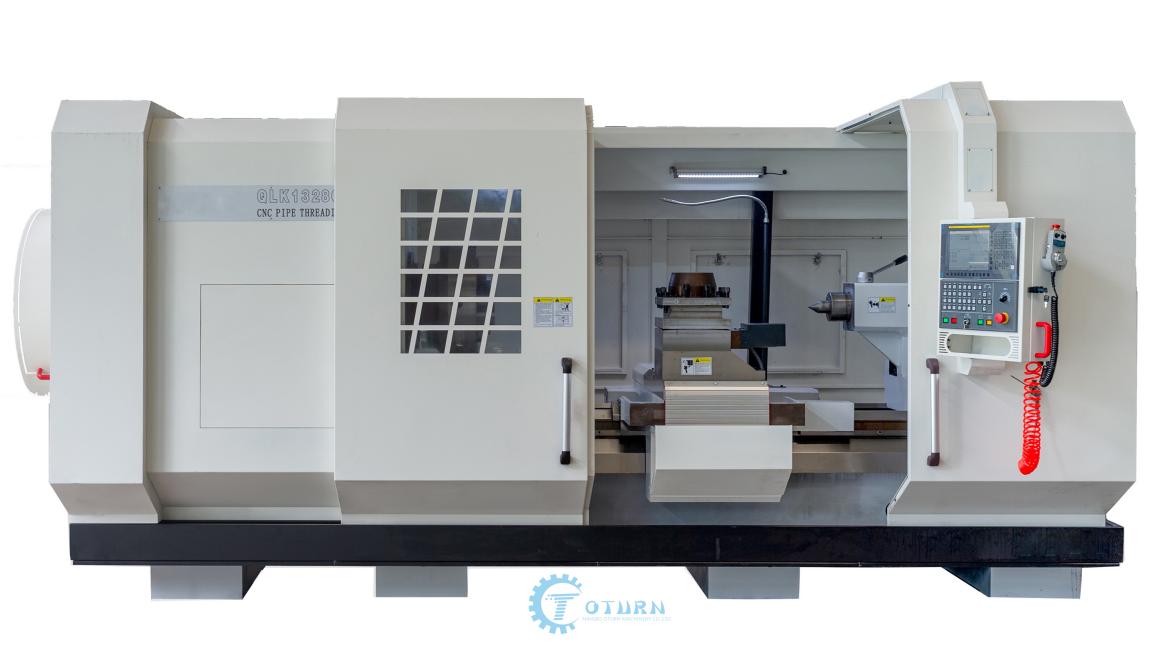

QLK1315 / QLK1320 / QLK1323 / QLK1325 / QLK1328 / QLK1336 / QLK1345

QLK1320

Siffofinda high qualitybututu zaren lathe:

1. Gado yana da asali na bangon bango mai Layer uku, kuma an shirya bangon baya tare da jirgin sama mai digiri 12, wanda ke inganta ingantaccen kayan aikin injin.

2. Babban sarkar watsawa shine watsawa mai daraja, wanda ke rage yawan kuzari da hayaniya na kayan aikin injin.

3. Yin amfani da akwatunan hydraulic daban-daban, lubrication na tsakiya, da sanyaya mai ƙarfi ba kawai rage yawan zafin jiki ba amma kuma yana kiyaye tsabta da lubrication na akwatin sandal.

QLK1336

QLK1336CNC Lathe kasar maisabuwar gyare-gyare ce ta CNC bututun zaren lathe. An ƙera babban tuƙi don dacewa da mitar aiki da aka ƙididdige na zaɓaɓɓen servo motor. Full stepless gudun tsari, m gudun tsari kewayon, wanda ba kawai gana da bukatun na high-gudun thread karewa, amma kuma yana da babban yankan yadda ya dace da kuma low amo.

Abũbuwan amfãni da fa'idar bututu zaren lathes

(1) Jikin inji

The nisa na jiki dogo ne 650mm, kayan ne HT300. Ultrasonic mita quenching aka cimma zuwa HRC52.The roughness ne Ra0.63 bayan nika da high-daidaici nika inji.It yana da high-daidaici da abrasion yi. Jikin na'ura wani tsari ne mai mahimmanci, wanda ke inganta ingantaccen kayan aikin injin.

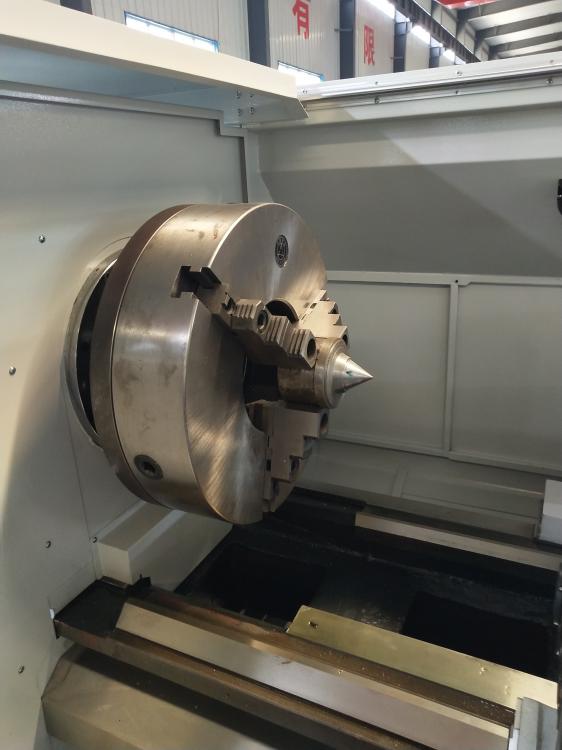

(2)CNC Mai kasar machinesAkwatin Shugaban

Nau'in akwatin akwatin kayan haɗin gwiwa, na'ura mai ƙarfi mai ƙarfi, servo motor,

Watsawa mai sauri biyu, ƙa'idar saurin taki.

Faɗin ka'idojin saurin sauri, ba kawai don biyan buƙatun kammala zaren tsayi mai tsayi ba, har ma don cimma ingantaccen yankewa.Quenched da daidaitaccen kayan niƙa, ɗakuna masu inganci, don tabbatar da ƙaramin ƙarar injin, ingancin sauti mai kyau.

Akwatin sandal yana amfani da lubrication mai ƙarfi mai ƙarfi na waje,

ba wai kawai yana rage zafi na sandal ba, har ma yana kiyaye tsabta da lubrication na akwatin sandal.

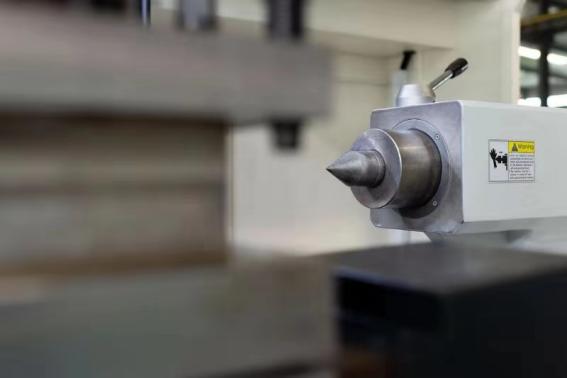

(3)Kayan wutsiya

Wannan kayan aikin injin daidai yake da φ120 tailstock spindle. Mohs 6# saman.

(4) Abincin axis biyu

Dukansu X axis da Z axis suna ɗaukar babban madaidaicin ƙwallon ƙwallon ƙwallon kai tsaye da tsarin dunƙule prestress tsarin tashin hankali. Ana amfani da madaidaicin ƙwallon ƙwallon ƙwallon ƙafa don matsayi da tallafi; Z shaft dunƙule goro tsarin simintin gyare-gyaren.

(5) CNC Turret

Masu karɓa (HAK21280) Mai riƙe kayan aiki na tsaye na CNC. Yana da halaye na babban madaidaici, juyawa mai laushi, aiki mai sauƙi da sauransu.

Dalilai hudu don zaɓarCNC bututu threadingmachine kolathe machining kasar mai

1.Dabututu zaren latheyana da halaye na babban digiri na aiki da kai, inganci mai inganci da daidaitattun daidaito, kewayon aikace-aikacen fa'ida, da aiki mai sauƙi.

2.The bedside akwatin da aka kore ta mita hira mota, tare da stepless gudun canji. Ƙunƙarar leda daga sanannun masana'antun cikin gida, ƙwanƙwasa guda uku daga sanannun samfuran gida.

3.The modular tsarin tsarin kula da lambobi yana da sauƙi don cirewa da sauƙi don kiyayewa. Axes x da z suna ɗaukar babban iko, injinan servo, aikin ci gaba, da ingantaccen dogaro.

4.It rungumi da simintin gadon gado, nunin farantin, m ciki hakarkarin shimfidar wuri, high madaidaicin ball dunƙule, high daidaito, da kuma ingantaccen watsa.

Babban Sassan Hotuna

Daidaitaccen tsari

Wutar kayan aikin lantarki ta tasha huɗu, lubrication na tsakiya ta atomatik, tsarin sanyaya, murfin kariyar da aka rufe da shi.

Ana amfani da wannan samfurin sosai a cikin ayyukan sarrafa injina a masana'antar injina, man fetur, sinadarai, kwal, binciken ƙasa, samar da ruwa da magudanar ruwa, da sauran masana'antu.

Sauran manyan sassan sun haɗa dabututu da haɗin kai.

Masana'antar man fetur wani yanki ne na masana'antu wanda ke hako mai (ciki har da man fetur, shale mai, da iskar gas) da kuma tace shi da sarrafa shi. Ya ƙunshi sashen binciken ƙasa na albarkatun mai, bunƙasa filin mai da haƙon mai, sufuri, tacewa da sarrafawa.

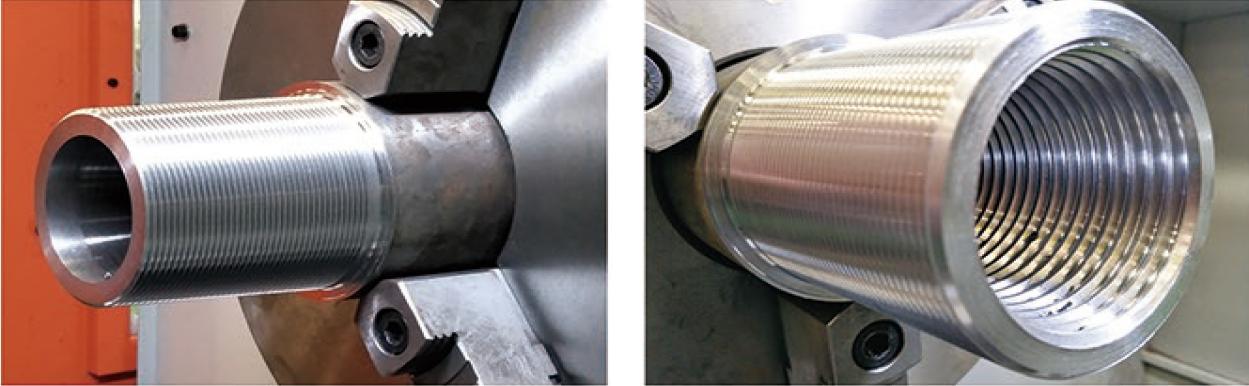

Kalmar da aka fi amfani da ita don bututun mai a masana'antar mai da iskar gas shine Tubin mai (OCTG). Manufar bututun mai na iya zama daban-daban: ana iya amfani da su don hakowa ko allurar iskar gas, mai, ruwa, tururi, da sauransu, kuma ana iya raba su zuwa casings ko tubing bisa ga takamaiman aikace-aikace. Ana amfani da casing a matsayin kariya mai kariya don taimakawa rijiyoyin mai don tsayayya da zaizayar gurɓataccen gurɓataccen ciki ko na waje don kula da dorewa; Ana amfani da bututu don allura ko fitar da mai.

Zaren bututuing kayan aikin injin ana amfani da su wajen sarrafa bututun mai, wadanda ake amfani da su sosai a harkar man fetur. Bututun karfe ne da ake amfani da shi wajen jigilar mai da iskar gas a rijiyoyin mai. Ana shigar da shi a cikin akwati, kuma man fetur da iskar gas na gudana daga bututun mai zuwa bakin rijiyar.

Akwai nau'i nau'i biyu na zaren tubing, ɗaya shine zaren bututun taper mai siffar V tare da dome zagaye kasa mai hakora 8 a kowace inch, ɗayan kuma shine zaren bututun taper mai siffar V tare da dome zagaye kasa a hakora 10 a kowace inch.

Zare shine ci gaba da fitowa tare da bayanin martabar hakori da aka tsara tare da layi mai karkace akan saman silinda ko mazugi. Akwai hanyoyi da yawa don yin zaren na'ura, kuma yawanci ana amfani da zaren a cikin injin gabaɗaya. Yaushemachining zarena kan lathe a kwance, dole ne a tabbatar da dangantakar motsi tsakanin kayan aiki da kayan aiki. A zahirizare juya, saboda dalilai daban-daban, motsi tsakanin igiya da kayan aiki yana da matsala a cikin wani hanyar haɗi, yana haifar da gazawar yayin juyawar zaren kuma yana shafar samar da al'ada. A wannan lokacin, ya kamata a warware shi cikin lokaci.

Yadda za a magance matsalar rashin ƙarfi, masu zuwa sune shawarwarin wasu ƙwararrun ma'aikatan bututun lathe:

1. Lokacin da aka juya tare da kayan aiki na karfe mai sauri, ya kamata a rage saurin juyawa kuma a kara man fetur.

2. Ƙara yankin giciye na arbor kuma rage tsayin tsayi (saboda arbor ba ta da tsayi sosai, yana da sauƙi ga girgiza yayin yankan)

3. Rage madaidaiciyar kusurwar gaba na kayan aikin jujjuyawar kuma daidaita daidaituwar goro na dunƙule farantin tsakiyar nunin (madaidaicin kusurwar gaba na kayan aikin juyi yana da girma sosai, kuma ɓangarorin ɓangarorin nunin ƙwanƙwasa na tsakiya yana da girma sosai, wanda zai sauƙaƙe kayan aiki)

4. A lokacin da high-gudun thread juya, da juya kauri na karshe yanke ne kullum mafi girma fiye da 0.1mm, da kuma kwakwalwan kwamfuta ake sallama perpendicular zuwa ga axis shugabanci (lokacin dazaren juyawa mai sauri, Juyin juyayi ya yi ƙanƙanta sosai ko kuma ana fitar da kwakwalwan kwamfuta a cikin hanyar da ba ta dace ba, yana da sauƙi don cire ƙwanƙwasa zaren).

5. Yakamata a yi amfani da mai mai tsayi mai tsayi ko mai jujjuya mai mai dauke da matsananciyar matsa lambaaiwatar da zarenna workpiece ta hanyar lathe. Yin amfani da man sarrafa ƙarfe na musamman zai iya daidaita matsalar rashin daidaito da ƙarancin inganci.

Lokacin aikawa: Satumba-21-2021