Lathe Driver Center Don Axle

Binciken fasahar axle na mota

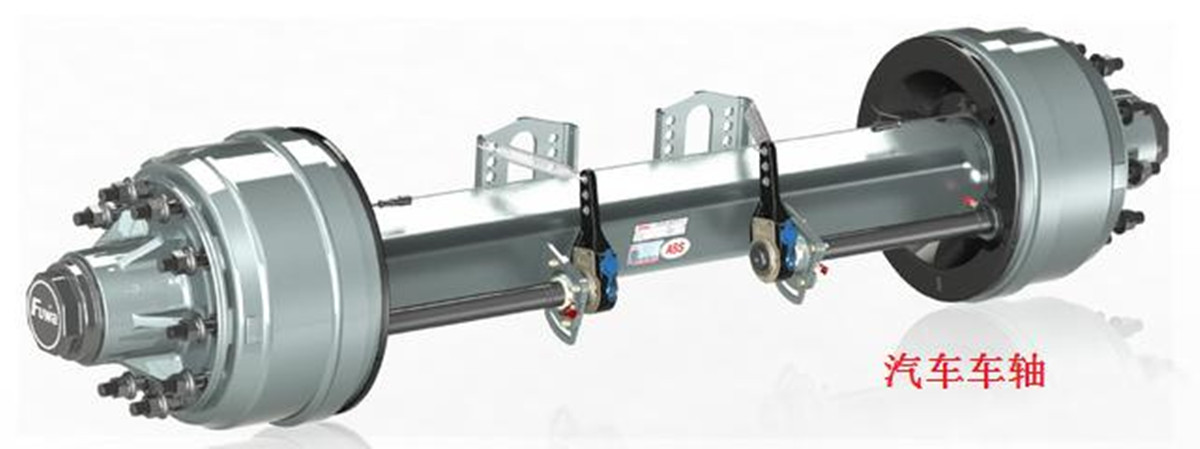

Mota axle

Axles masu ƙafafu a ɓangarorin biyu na ƙasa (frame) ana kiransu gaba ɗaya azaman axles na mota, kuma aksles masu ƙarfin tuƙi ana kiran su axles. Babban bambanci tsakanin su biyun shine ko akwai tuƙi a tsakiyar axle (axle). A cikin wannan takarda, ana kiran axle na mota tare da naúrar tuƙi ana kiran motar axle, kuma abin hawa wanda ba shi da tuƙi ana kiransa axle na mota don nuna bambanci.

Tare da karuwar buƙatun kayan aiki da sufuri, fifikon axles na motoci, musamman tireloli da manyan tireloli, a cikin ƙwararrun sufuri da ayyuka na musamman suna ƙara ƙara bayyana, kuma buƙatun kasuwa ya ƙaru sosai.

Wannan fasaha yana nazarin tsarin mashin din din din din din din din din din din din din din din din din din din din din din din din din din din din din din din din din din din din), yana fatan taimakawa abokan ciniki su zabi na'urar CNC mafi dacewa.

Rarraba axle na mota:

Nau'o'in axles sun bambanta bisa ga nau'in birki, kuma sun kasu zuwa: faifan birki, birki na ganga, da dai sauransu.

Dangane da girman tsarin diamita na shaft, an raba shi zuwa: axle na Amurka, axle na Jamus; da dai sauransu.

Bisa ga tsari da tsari, an raba shi zuwa:

dukan: m square tube axle, m square tube axle, m zagaye axle;

tsaga jiki: shaft head + m shaft tube waldi.

Daga abubuwan sarrafawa na axle, ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ramuka suna da alaƙa da zaɓin kayan aikin sarrafawa.

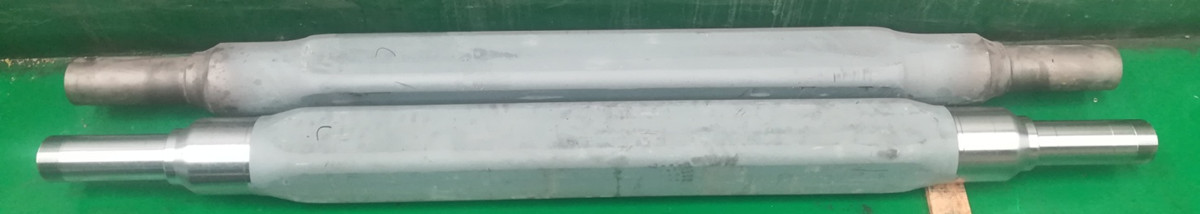

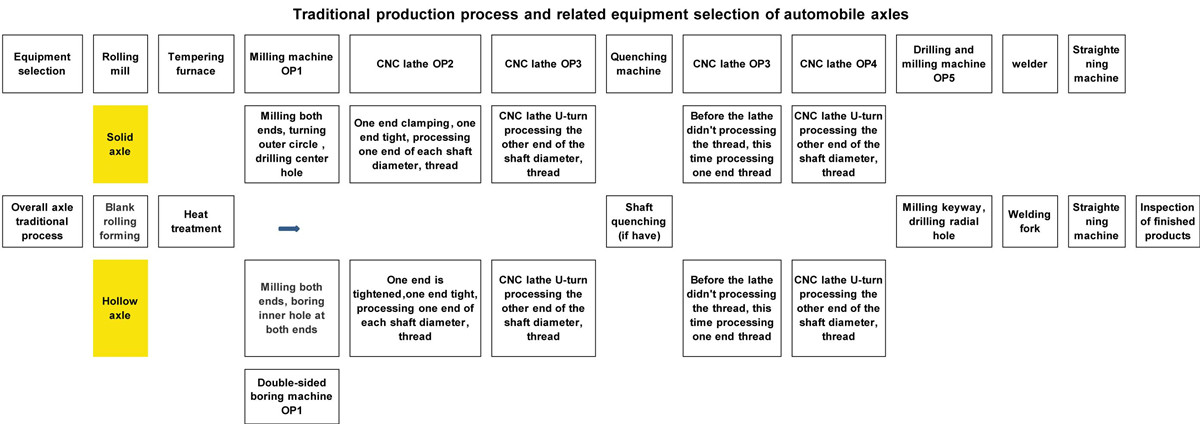

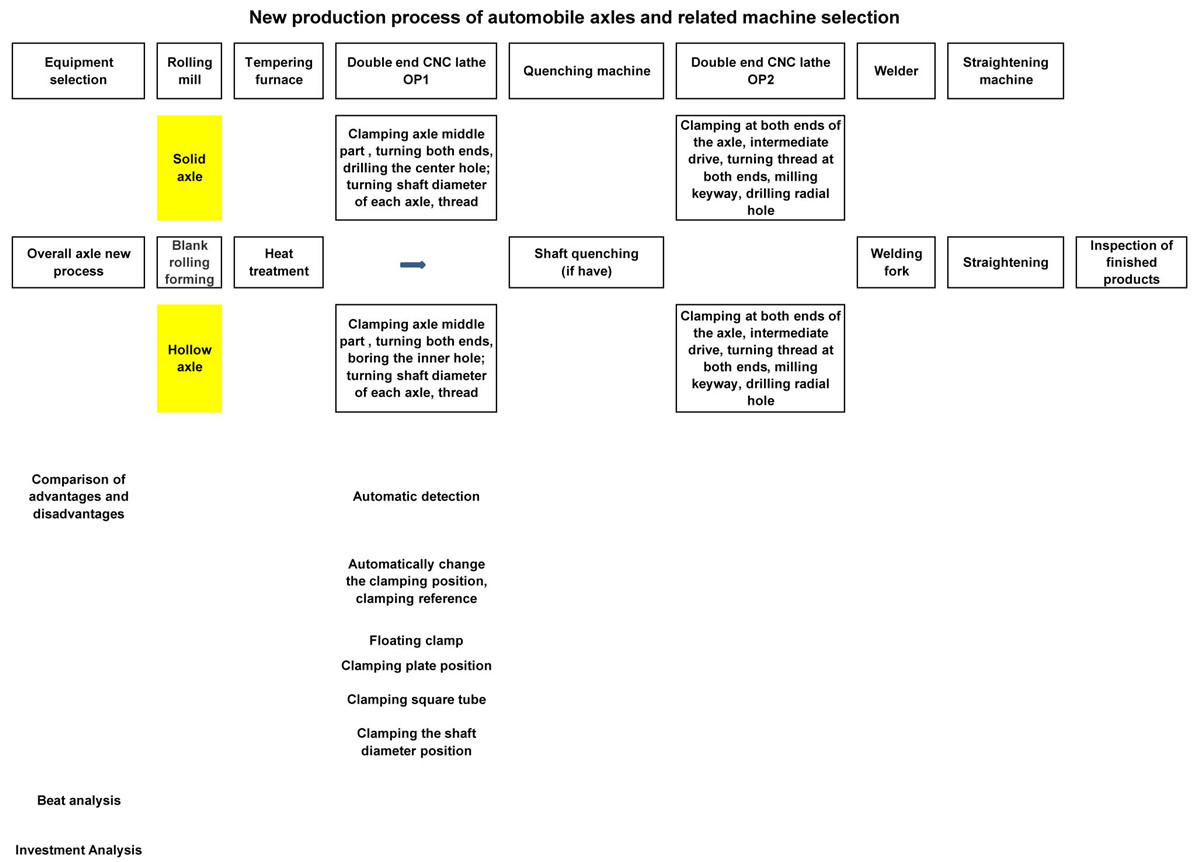

Wadannan su ne bincike na samar da tsari na dukan axle (kuma kasu kashi m da m; square tube da zagaye tube), da kuma tsaga axle (m da m shaft shugaban + m shaft tube waldi), musamman, da machining tsari. Ana nazarin don mafi kyawun zaɓin injin da ya fi dacewa.

Tsarin samarwa da na'ura don axles na mota:

1. Tsarin samar da al'ada na gabaɗaya axle:

Daga tsarin samar da axle na sama, ana buƙatar aƙalla nau'ikan kayan aikin injin guda uku don kammala aikin injin: injin niƙa ko na'ura mai ban sha'awa mai ban sha'awa, CNC lathe, hakowa da injin niƙa, kuma CNC lathe yana buƙatar juyawa (wasu abokan ciniki suna da zaba CNC lathe mai kai biyu). Game da sarrafa zaren, idan diamita na ramin ya kashe, ana sarrafa shi bayan an kashe shi; idan babu quenching, ana sarrafa shi a cikin OP2 da OP3, kuma an cire kayan aikin injin OP4 da OP5.

Daga sabon tsarin samarwa, injin niƙa da aka yi amfani da shi don machining (m axle) ko na'ura mai ban sha'awa mai ban sha'awa (ramin axle) da CNC lathe, OP1 milling na gargajiya, OP2, OP3 juya jerin, har ma da OP5 hakowa da niƙa Ana iya maye gurbinsa. ta hanyar CNC lathe OP1.

Don ƙaƙƙarfan axles inda diamita na shaft baya buƙatar quenching, duk abubuwan da ke cikin injin ɗin za a iya kammala su a cikin saiti ɗaya, gami da maɓalli na niƙa da ramukan radial. Don ramukan axles inda diamita na shaft ba ya buƙatar kashewa, ana iya samun daidaitaccen madaidaicin juyawa ta atomatik a cikin kayan aikin injin, kuma ana iya kammala abun cikin injin ta kayan aikin injin guda ɗaya.

Zaɓi lathes na CNC na musamman na ƙarshen-ƙarshe biyu don na'ura na axles yana rage mashin ɗin da muhimmanci sosai, kuma nau'in da adadin kayan aikin injin da aka zaɓa kuma za a rage.

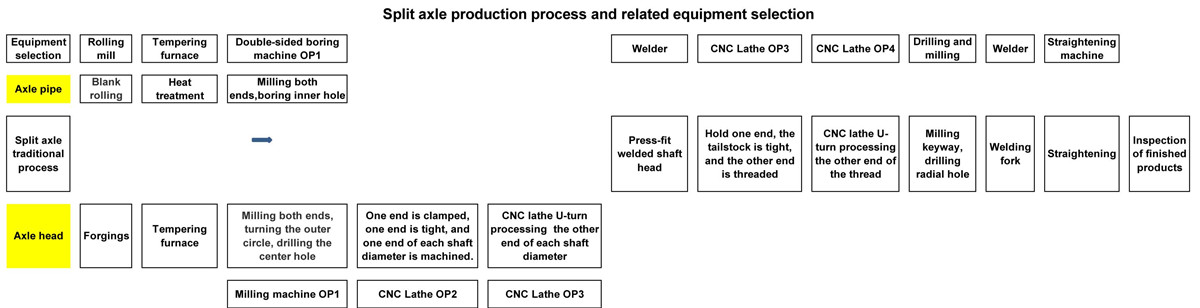

3.Split axle samar da tsari:

Daga tsarin da ke sama, kayan aiki na kayan aiki na bututun axle kafin waldawa kuma za'a iya zaɓar su azaman lathe CNC mai ƙare biyu. Don sarrafa axle bayan waldawa, lathe CNC na musamman don axles-karshen biyu ya kamata ya zama zaɓi na farko: aiki na lokaci ɗaya a ƙarshen duka, ingantaccen aiki da ingantaccen daidaiton machining. Idan maɓalli da ramin radial a duka ƙarshen gatari suna buƙatar injina, injin ɗin kuma ana iya sanye shi da mai riƙe kayan aikin wuta don sarrafa maɓalli na gaba da ramin radial tare.

4.A amfani da fasalin sabon tsari zaɓi na'ura:

1) Tattaunawa na tsari, rage lokutan workpiece clamping, rage karin aiki lokaci, ta amfani da lokaci guda fasahar sarrafa a duka iyakar, da samar da yadda ya dace yana inganta sosai.

2) Ƙaƙwalwar lokaci ɗaya, aiki guda ɗaya a ƙarshen duka yana inganta daidaiton machining da coaxial na axle.

3) Rage aikin samarwa, rage jujjuyawar sassa akan wurin samarwa, inganta ingantaccen amfani da rukunin yanar gizon, da kuma taimakawa haɓaka tsari da sarrafa abubuwan samarwa.

4) Saboda yin amfani da kayan aiki masu inganci, ana iya sanye shi da na'urori masu kayatarwa da saukewa da na'urorin ajiya don cimma cikakkiyar samarwa da kuma rage farashin aiki.

5) An ƙulla kayan aiki a matsakaicin matsayi, ƙuƙwalwar abin dogara ne, kuma ƙarfin da ake buƙata don yankan kayan aikin inji ya isa, kuma ana iya yin babban adadin juyawa.

6) Za a iya sanye da kayan aikin injin tare da na'urar ganowa ta atomatik, musamman ga madaidaicin axle, wanda zai iya tabbatar da kauri iri ɗaya na axle bayan machining.

7) Don ƙananan axles, lokacin da aka gama ramukan ciki a ƙarshen ƙarshen OP1, abokin ciniki na gargajiya zai yi amfani da ƙarshen ɗaya don ɗaga matse kuma ɗayan ƙarshen don amfani da wutsiya don ƙara kayan aiki don juyawa, amma girman girman. ramin ciki daban. Don ƙaramin rami na ciki, ƙarfin ƙarfafawa bai isa ba, ƙarar ƙarar ƙarar ba ta isa ba, kuma ba za a iya kammala yankan inganci ba.

Don sabon lathe fuska biyu, gatari mara kyau, lokacin da ramukan ciki a ƙarshen abin hawa biyu suka ƙare, injin ɗin yana canza yanayin matsawa ta atomatik: ana amfani da ƙarshen biyu don ƙara kayan aikin, kuma tsakiyar motar yana iyo kan aikin aikin. don watsa juzu'i.

8) Za'a iya matsar da kayan kwalliyar kayan aiki tare da ginanniyar kayan aiki na hydraulic clamping a cikin hanyar Z na injin. Abokin ciniki zai iya riƙe matsayi a cikin bututun murabba'in tsakiya (bututun zagaye), matsayi na farantin ƙasa da matsayi na diamita na axle kamar yadda ake buƙata.

5.Kammalawa:

Dangane da yanayin da ke sama, amfani da lathes na CNC mai ƙarewa biyu zuwa injin axles na mota yana da fa'idodi masu mahimmanci akan hanyoyin gargajiya. Fasaha ce ta ci gaba wacce za ta iya maye gurbin kayan aikin injin gargajiya dangane da tsarin samarwa da tsarin injin.

Sashen tsakiya na

6.Axle abokin ciniki case

Gabatarwar Axle-karshen Ƙarshen Ƙarshen CNC na Musamman

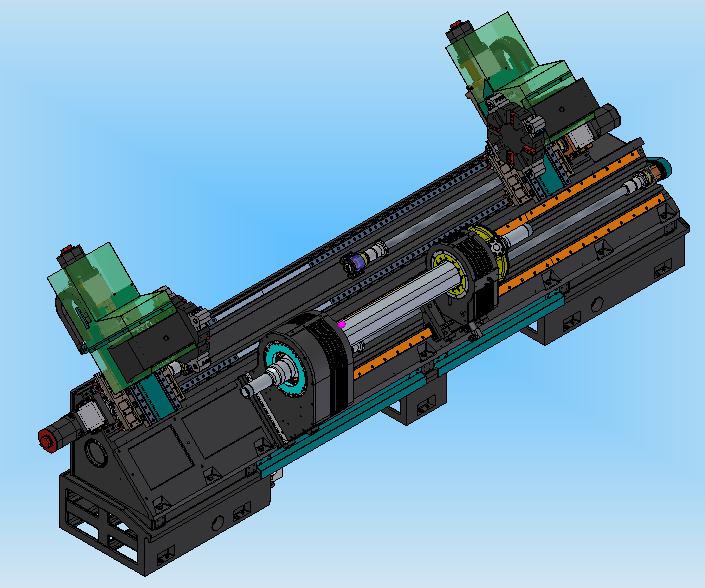

Kewayon sarrafa axle: ∮50-200mm, □50-150mm, tsayin aiki: 1000-2800mm

Tsarin injin da gabatarwar aiki

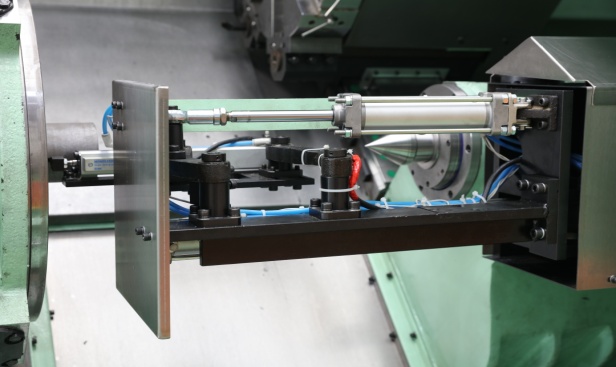

Kayan aikin injin yana ɗaukar shimfidar shimfidar gado na 45°, wanda ke da ƙaƙƙarfan ƙaƙƙarfan ƙaura da ƙaurawar guntu mai sauƙi. An shirya kayan hawan kai tare da aikin matsawa na tsaka-tsaki a tsakiyar gadon, kuma an shirya masu riƙe da kayan aiki biyu a bangarorin biyu na akwatin sandal. Matsakaicin tsayin mashin ɗin shine 1200mm kuma matsakaicin tsayin mashin ɗin shine 2800mm. An karɓi jagorar birgima, kuma kowane shaft ɗin ciyarwar servo yana ɗaukar babban dunƙule ƙwallon bebe, kuma ana haɗa haɗin haɗin roba kai tsaye, kuma ƙarar ta yi ƙasa kaɗan, daidaiton matsayi da madaidaicin maimaitawa yana da girma.

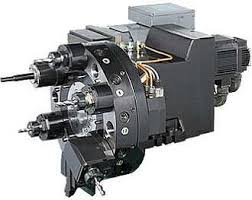

■ Na'urar tana da tsarin sarrafa tashoshi biyu. Ana iya haɗa masu riƙe da kayan aiki guda biyu zuwa sandar a lokaci guda ko dabam don kammala aikin injin lokaci ɗaya ko jere na ƙarshen ɓangaren biyun.

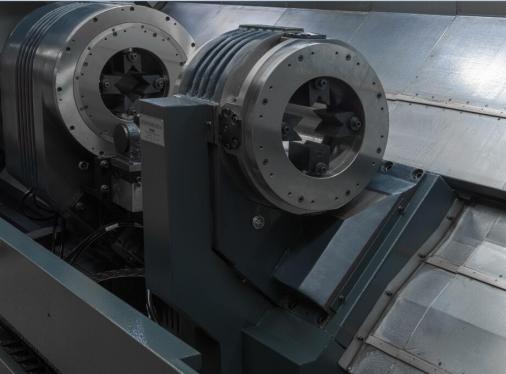

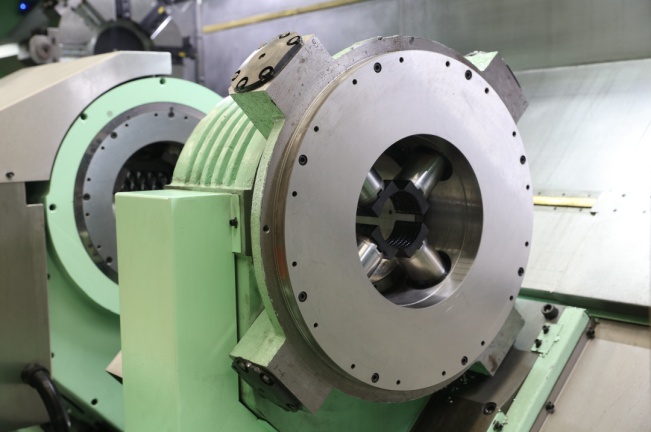

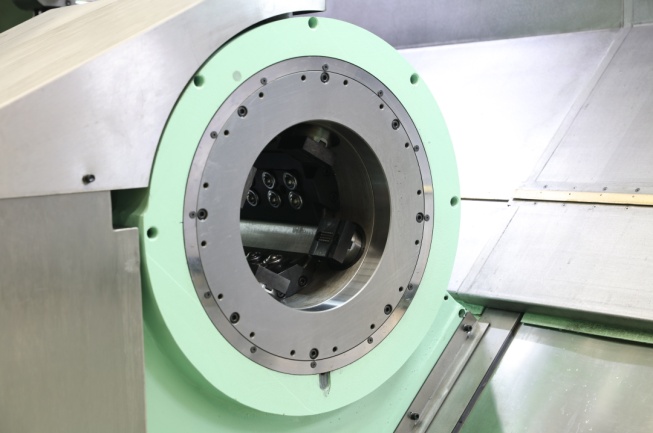

■Mashin ɗin yana sanye da manyan hanu biyu. Ana gyara babban abin hawa a tsakiyar gadon, kuma motar servo tana ba da wutar lantarki zuwa babban shaft ta bel ɗin hakori. An shigar da akwatin sub-spindle a kan ƙananan jagorar jagorar kayan aikin injin, coaxial tare da babban akwatin sandal, kuma ana iya motsa shi axially ta motar servo don sauƙaƙe ɗauka da sauke sassa, kuma yana dacewa don daidaita matsi daban-daban. matsayi. Lokacin yin sassan mashin ɗin, ana kulle gunkin sub-spindle zuwa layin dogo na inji. Ana tabbatar da daidaiton coaxial na manyan kantunan biyu ta hanyar masana'anta, wanda ke haifar da mafi girman matakin daidaitawar sassan injinan.

■The Headstock yana haɗa tsarin dunƙulewa, na'ura da tsarin rarraba mai, kuma yana da ƙaƙƙarfan tsari da ingantaccen aiki. Ƙayyadaddun diamita na clamping da nisa na headstock an ƙaddara su ta hanyar sassan axle na abokin ciniki.

Ana rage jinkirin babban abin hawa ta matakai biyu na bel da kayan aiki, yana ba da damar igiya don fitar da babban juzu'i. Ana shigar da matse a gefen hagu na babban abin hawa da kuma ƙarshen hannun dama na ƙaramin kan gadon don gane manne sassan. Lokacin da babban kwandon kai ya motsa sassan don jujjuya su, ƙananan kayan ƙwanƙwasa ƙwanƙwasa suna juyawa tare da babban hanu.

An sanye shi da silinda na radial guda uku (4 radial cylinders idan duka kayan zagaye da kayan murabba'in suna clamped), piston yana ramawa da matsa lamba na hydraulic, kuma ana shigar da ƙusoshin a ƙarshen piston don gane kai- tsakiya na sassa. Matsawa. Yana da sauri da sauƙi don canza ƙwanƙwasa lokacin canza sassan. Ana daidaita ƙarfin matsawa ta hanyar tsarin hydraulic matsa lamba na hydraulic. Lokacin da aka nada sashin, matsin yana juyawa tare da babban ramin, kuma tsarin rarraba mai yana ba da mai ga maƙalar, ta yadda maƙalar ta sami isasshen ƙarfi yayin juyawa. Maƙerin yana da fa'idodin babban ƙarfin matsewa da babban bugun farata.

∎ Domin magance matsalar kaurin bango iri ɗaya bayan injin gatari na abokin ciniki, na'urar za a iya sanye ta da na'urar tantance kayan aiki ta atomatik. Bayan an gama ƙulla axle, aikin aikin zai gano ta atomatik cewa binciken ya faɗaɗa kuma yana auna matsayin aikin; bayan an gama aunawa, na'urar zata koma cikin rufaffiyar sarari.

Domin daban-daban machining tafiyar matakai na m axles, idan hali matsayi da ake amfani da matsayin clamping tunani, da inji tsarin da atomatik clamping da clamping za a iya bayar da shirye-shirye tailstock a ɓangarorin na babba da kuma karin sandal shugabannin gamuwa. bukatun na'ura daya. Ana sa ran kammala sarrafa matakai biyu a lokaci guda. A lokaci guda kuma, yana sa sassan na'ura ta atomatik da saukewa suna da ƙarin zaɓi mafi kyau.

■Masu riƙon kayan aiki na hagu da dama ana iya sanye su da na yau da kullun na jujjuya kayan aiki ko tururuwan wuta. Suna da ayyukan hakowa da niƙa, waɗanda za su iya kammala hakowa da niƙa manyan sassa.

∎ Kayan aikin na'ura an rufe shi sosai kuma an sanye shi da na'urar shafawa ta atomatik da na'urar cire guntu ta atomatik (gaba). Yana da kyakkyawan aikin kariya, kyakkyawan bayyanar, aiki mai sauƙi da kulawa mai dacewa.

∎ An ƙayyade ƙayyadaddun ƙayyadaddun inji da ƙayyadaddun ƙayyadaddun bayanai bisa ga buƙatun axle da buƙatun abokin ciniki, kuma ba za a sake maimaita su anan ba.

Na gode da hankalin ku!