Lathe Driver na tsakiya Don bututu mai katanga

Tube Sirarar Katanga da sassan Tube

Maganin Fasaha

1.Process bincike na sarrafa bakin ciki-banga cylindrical sassa

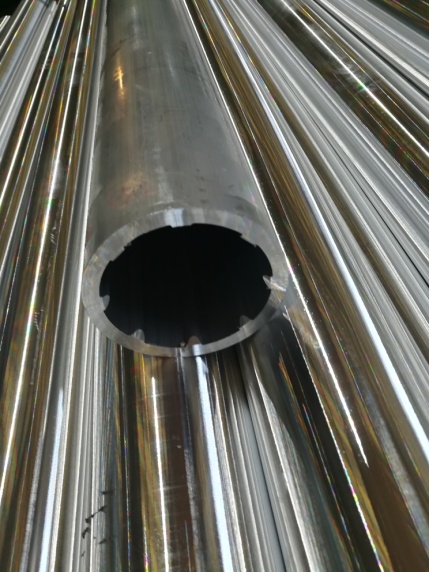

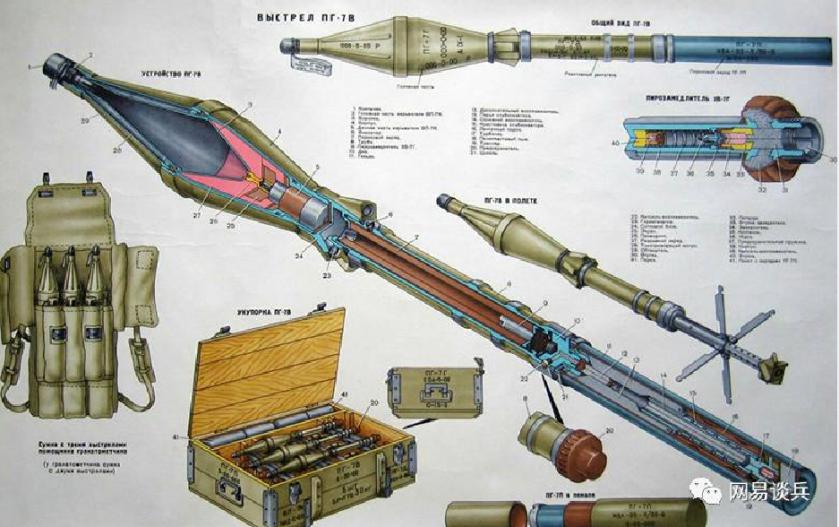

Bututu mai bakin bango da sassan bututu koyaushe sun kasance wuri mai wahala a cikin injina. Misali: jikin bindigar da aka yi amfani da shi wajen hako injinan mai, ciki da waje na na'urar buguwa ta kasa da kasa, harsashi na ciki da na waje na mai kariyar famfo mai, bugu na injin bugu, ganga mai jujjuyawa. injin yadi, injin watsawa Conveyor abin nadi, hakowa-rami da kayan fashewa

Kambun na waje, da sauransu, ba shakka, sun haɗa da harsashi na harsashin soja ko na farar hula.

1.1 Na yau da kullun

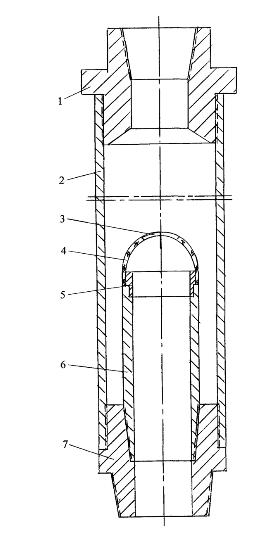

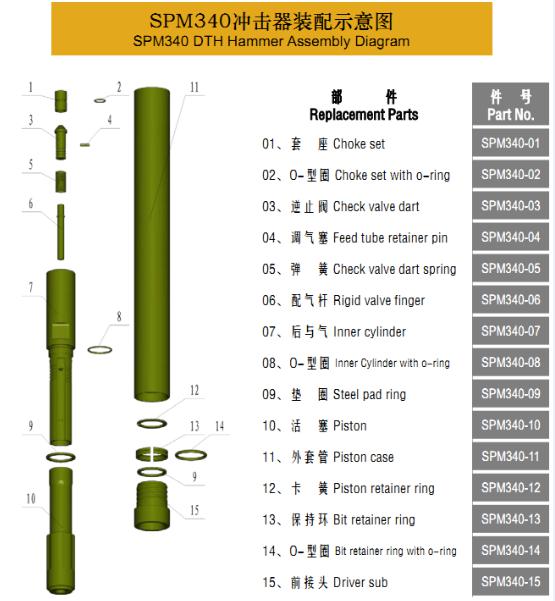

Tsarin bindigar mai lalata: manyan abubuwan da ke tattare da bindigar su ne jikin bindiga, shugaban bindiga, wutsiyar bindiga, haɗin gwiwa, na'urar fashewa, zoben rufewa da mariƙin harsashi. Abubuwan buƙatun aiki na asali na bindigar harbi. A matsayin babban sashi na mai siffa mai siffar makamashi, babban aikin da ake yi na harbin bindiga shine karfin injinsa. Sai kawai lokacin da kaddarorin injinsa sun cika, za a iya tabbatar da mai sifar makamashi mai siffa Yiwuwa da aminci yayin huɗawar ƙasa.

Mai kare famfo mai

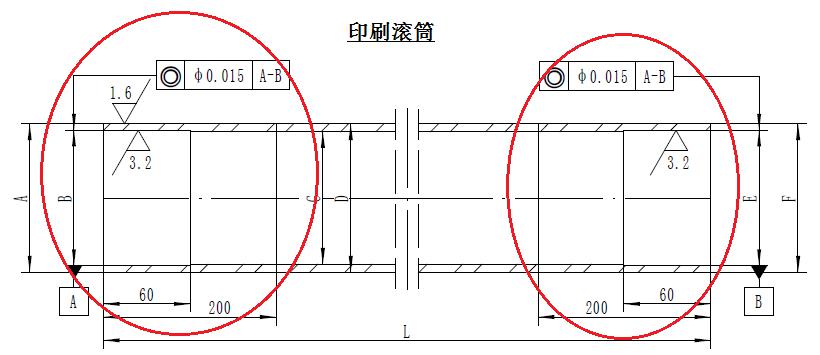

Buga Silinda

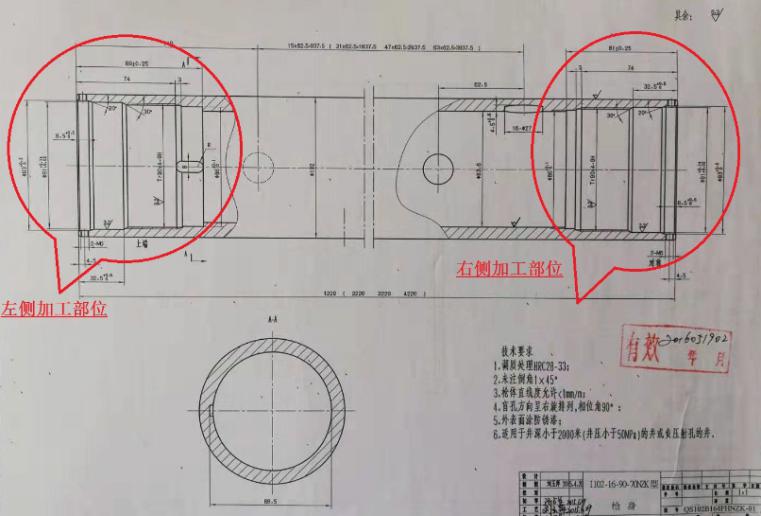

Kwatanta sabbin da tsoffin fasahar sarrafa harsashi

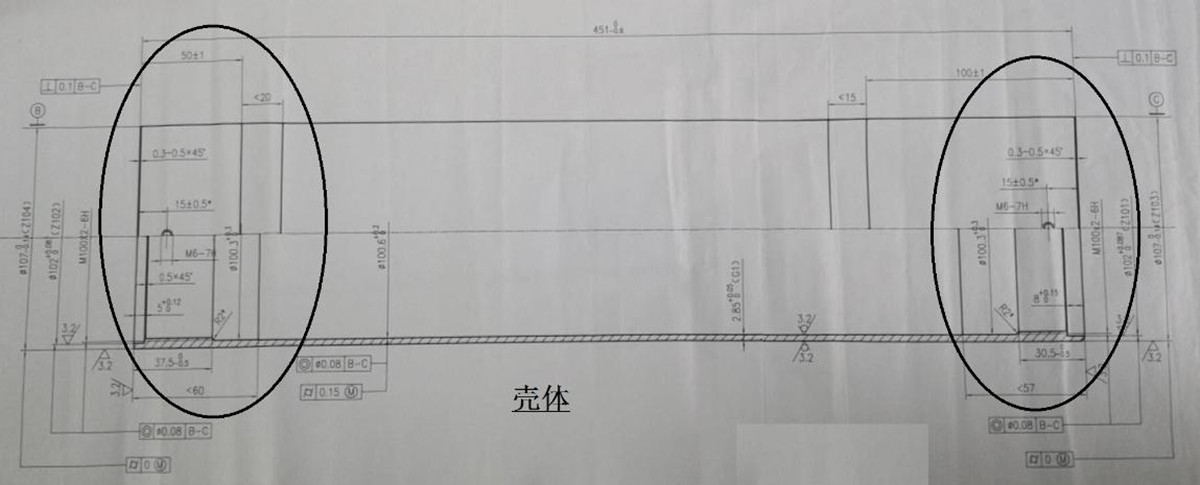

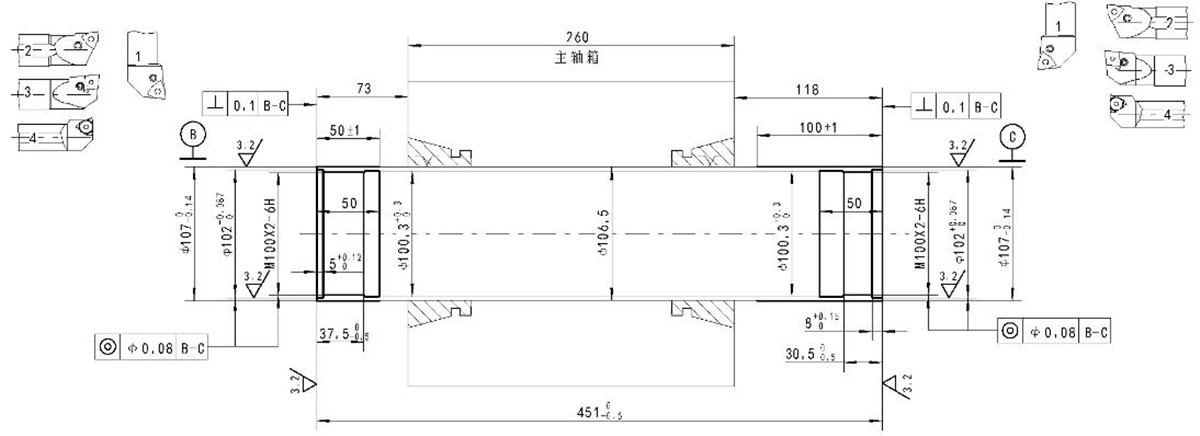

Irin wannan nau'in sassa yana da abu guda ɗaya: bututu masu bakin ciki da aka kafa ta hanyar mirgina ko jujjuya ana sarrafa su a ƙarshen biyu, rami na ciki (don haɗuwa), zaren rami na ciki (don haɗi), ɗan ƙaramin waje, zaren waje ( idan Ana Bukata), ciki da waje fanko sipes da chamfer

1.2. Binciken tsari.

1) Fasahar sarrafa kayan gargajiya:

Gabaɗaya, ɗayan ƙarshen lathe ana amfani da shi don matsewa, ɗayan kuma yana amfani da itacen wutsiya don saman rami na ciki da kuma tsakiyar motar, sannan a yi amfani da firam ɗin tsakiya don tallafawa, sannan kuma yana jin gajiyar rami na ciki na wannan ƙarshen. , ƙarshen fuskar mota, da injinan da za'a iya buƙata don jujjuya sassan da'irar waje, ko sassan matsi da ake buƙata don juyawa da juyawa.

Workpiece U-juya: ciki goyon baya ko m matsa Silinda jiki, tailstock tightening da workpiece, mota cibiyar frame soket, tsakiyar frame support, re-m ciki rami, mota karshen fuska, m da'irar.

Idan coaxial ramukan ciki a duka ƙarshen silinda ya ɗan yi girma, ana iya maimaita aiki sau da yawa.

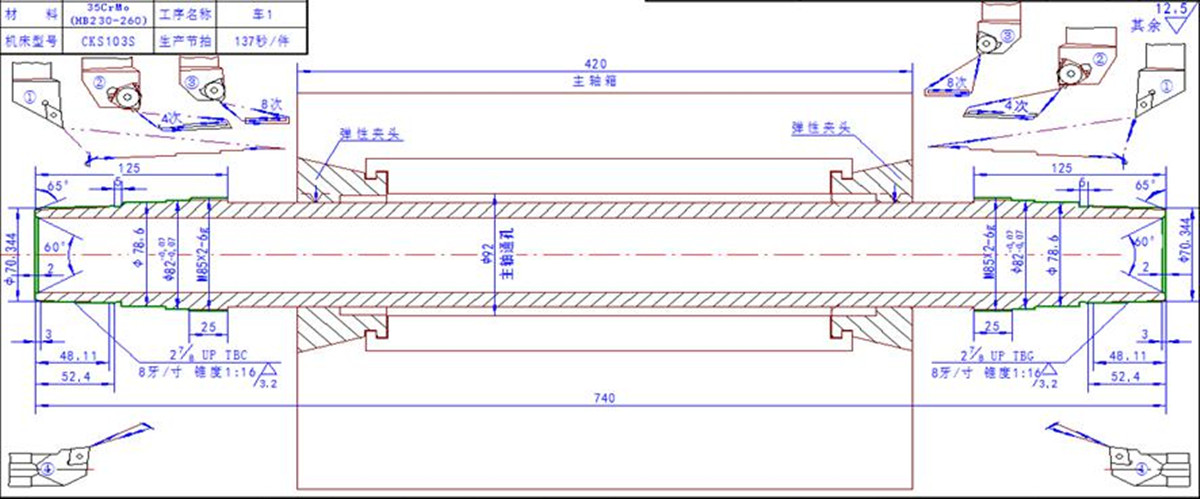

2) Amfani da fasahar sarrafa lathe CNC mai ƙare biyu:

Ana iya kammala aikin sarrafa abubuwan da ke sama a cikin ɗaki ɗaya, kuma ana iya sarrafa ƙarshen duka biyu a lokaci guda, wanda ba kawai rage yawan kayan aikin injin ba, har ma yana rage saurin aiki da sarrafa kayan aiki, kuma yana haɓaka haɓakar samarwa sosai. . Tun da ana sarrafa ƙarshen duka biyu a lokaci guda, coaxial na workpiece shima yana da tabbacin dogaro.

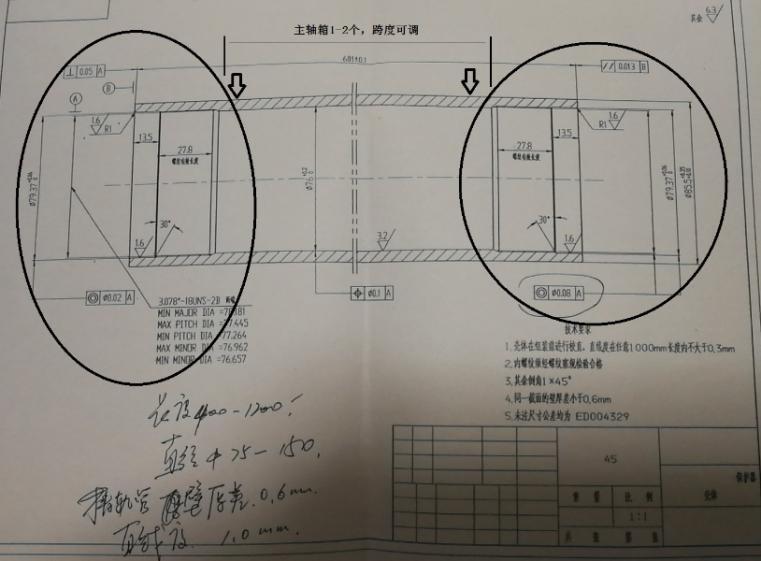

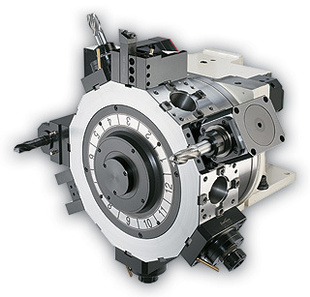

Musamman: dangane da tsawon kayan aikin, ana iya amfani da katako ɗaya ko biyu don matsa da da'irar waje na workpiece. An ƙaddara diamita mai maƙalli da nisa na ƙugiya na headstock bisa ga diamita da tsawon aikin aikin. Juyawa biyu na tasha 8/12 a lokaci guda suna aiwatar da ƙarshen fuska, rami na ciki da da'irar waje a ƙarshen duka. Kamar yadda adadin kayan aikin da za a iya shigar ya isa, zai iya biyan bukatun sarrafa lokaci guda na sassa masu rikitarwa.

Idan ɓangaren maƙerin waje na kayan aikin injin a cikin wannan jeri yana buƙatar sarrafa shi, to, yi amfani da kayan aikin injin don ninka saman ramukan ciki a ƙarshen ƙarshen aikin don juyawa ko niƙa da'irar waje.

Har ila yau, akwai abokan ciniki waɗanda ke amfani da injin niƙa marar tsakiya don niƙa da'irar waje a gaba, sa'an nan kuma amfani da lathe CNC mai ƙare biyu don aiwatar da ramukan ciki da ƙarshen fuskoki a duka ƙarshen zuwa bukatun tsari.

3) Lambobin sassa na silinda da aka sarrafa ta hanyar lathes CNC-karshen biyu:

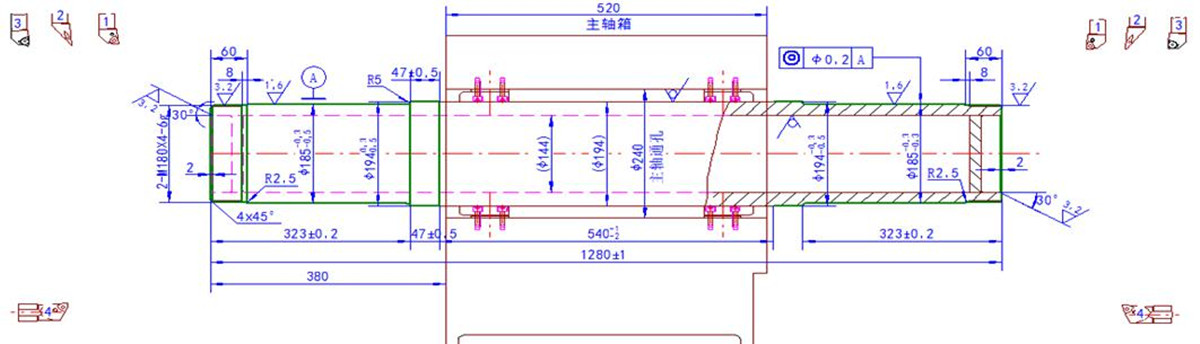

① Silinda injin bugu, zaɓi samfurin SCK208S (ta amfani da akwatin sandal biyu).

②Ana amfani da ƙirar SCK309S (stock guda ɗaya) don sarrafa babban gatari na mota.

Ana amfani da samfurin SCK105S don sarrafa bututun bakin bango na soja.

④Don sarrafa bututun bakin bango na soja, zaɓi samfurin SCK103S

⑤ SCK105S an zaɓi samfurin don sarrafa bututun mai na injinan mai.

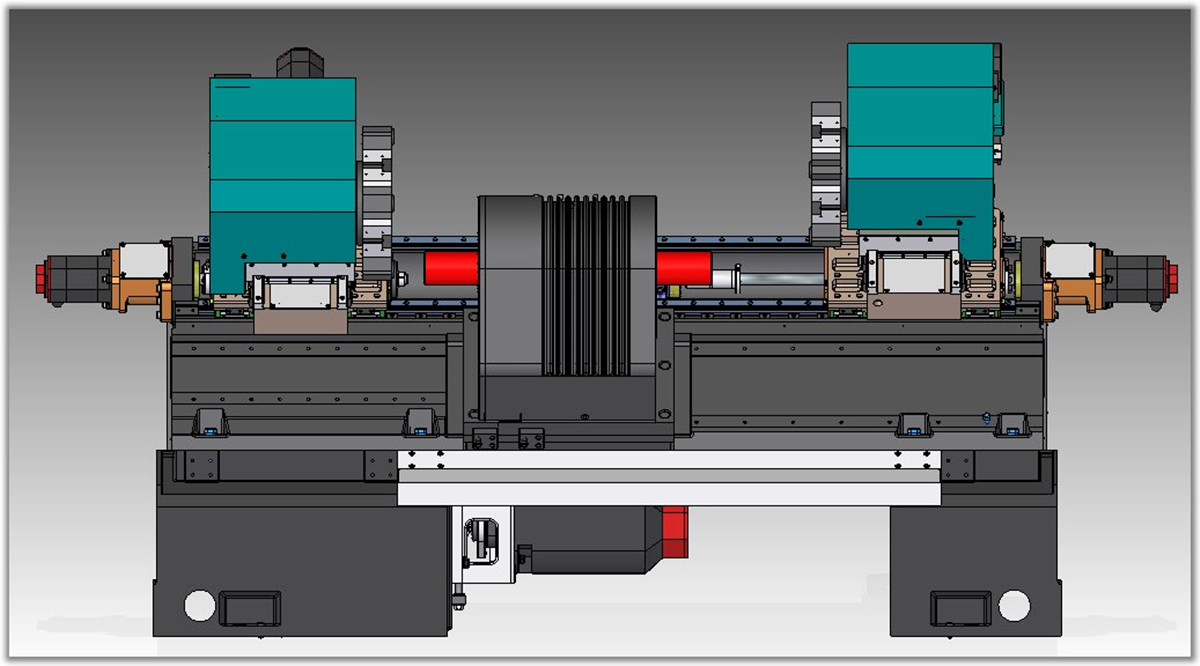

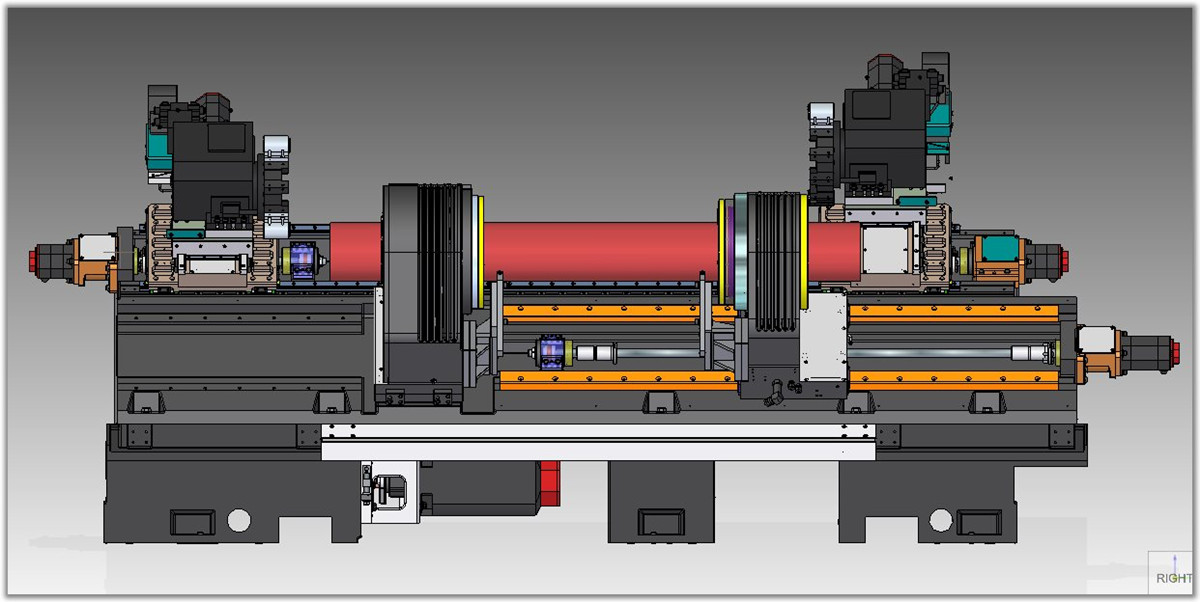

Jerin SCK Biyu-ƙarshen CNC Lathe Gabatarwa

∎ Ƙwararren CNC lathe mai tsayi biyu-biyu nau'i ne na ingantaccen aiki da ingantaccen kayan aikin masana'antu. Yana iya lokaci guda kammala da'irar waje, ƙarshen fuska da rami na ciki na ƙarshen biyu na workpiece a cikin ɗaki ɗaya. Idan aka kwatanta da tsarin al'ada na clamping sassa sau biyu da juyawa, yana da fa'idodi na ingantaccen samarwa, mai kyau coaxiality da daidaitattun sassan da aka sarrafa.

A halin yanzu, akwai nau'ikan samfura guda 10, diamita na clamping: φа %%, aiki tsawon: 140-3000mm; Idan an yi la'akari da shi musamman don sassan harsashi na tube, diamita na clamping na iya kaiwa φ400 mm.

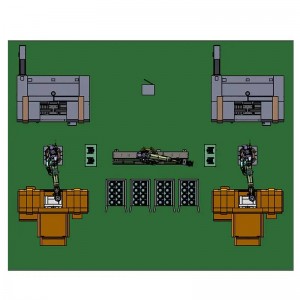

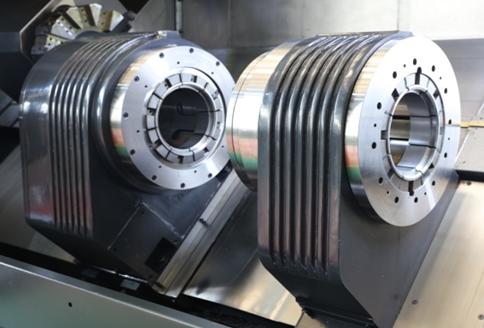

∎ Gabaɗayan injin ɗin yana da shimfidar shimfidar gado 450, wanda ke da tsauri mai kyau da kuma cire guntu mai dacewa. Akwatin sandal mai matsakaicin tuƙi da aikin ɗaurewa an shirya shi a tsakiyar gadon, kuma an shirya kayan aiki guda biyu a bangarorin biyu na akwatin sandal.

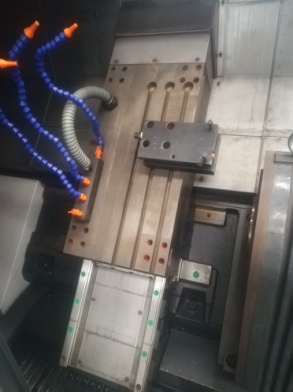

■Amfani da tsarin sarrafa tashoshi biyu, ana iya haɗa kayan aikin guda biyu tare da igiya a lokaci ɗaya ko dabam don kammala sarrafa lokaci ɗaya ko sarrafa sassan sassan biyu.

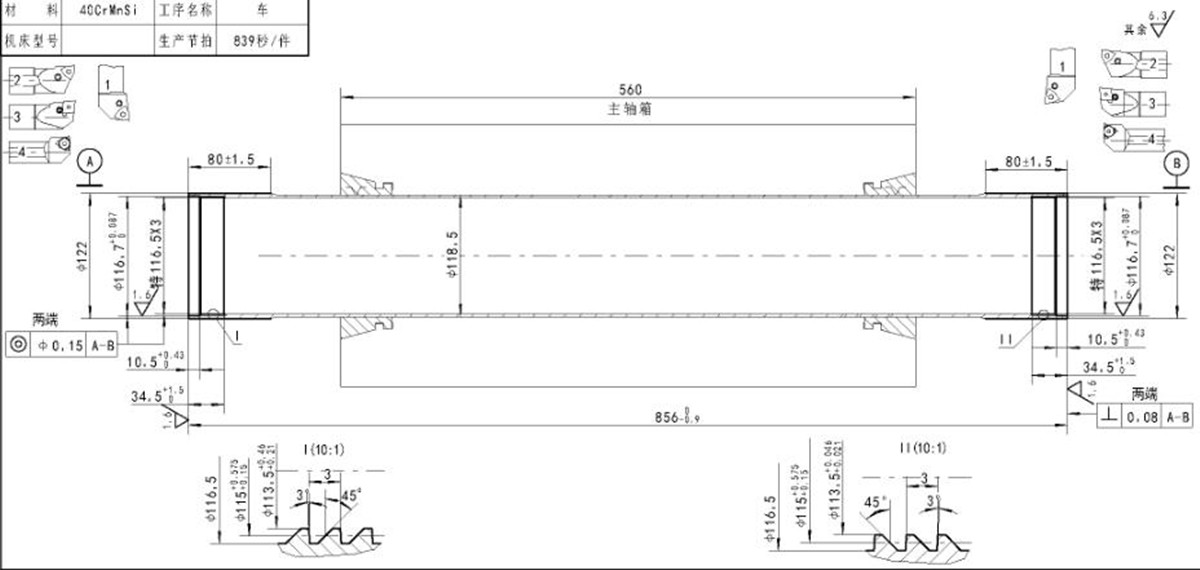

∎ Kowane servo feed axis yana ɗaukar ƙwallon ƙwallon shiru mai ƙarfi, kuma haɗin gwiwa na roba yana da alaƙa kai tsaye, tare da ƙaramar amo, babban matsayi daidai da daidaito mai maimaitawa.

∎ Dangane da tsawon aiki na kayan aiki daban-daban, ana iya sanye take da 1-2 tsaka-tsaki na tuƙi. Daga cikin su, babban akwatin sandal na hagu yana gyarawa, kuma akwatin da ke gefen dama yana motsa shi ta hanyar servo motor don motsa ƙwallon ƙwallon a cikin hanyar Z. Yana iya amfani da babban akwati kawai don matsawa don kammala sarrafa gajerun sassa; Hakanan yana iya amfani da ƙwanƙwasa guda biyu don manne tare don kammala sarrafa dogayen sassa.

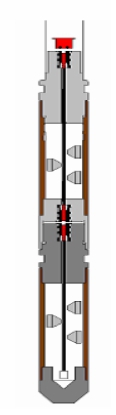

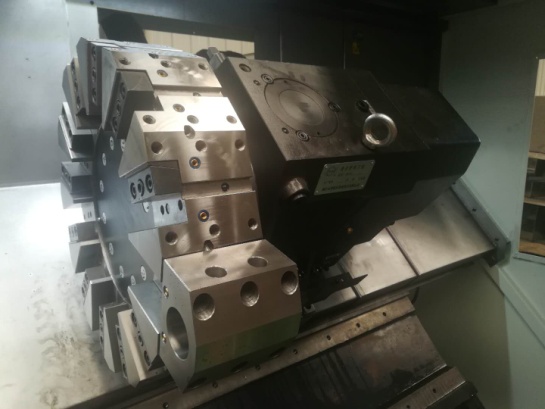

∎ Akwatin sandal ɗin yana haɗa sassa biyar na tsarin dunƙulewa, ƙugiya, silinda mai ɗaure, tsarin rarraba mai da na'urar tuki, tare da ƙaramin tsari da ingantaccen aiki. Na'urorin matsawa dukkansu ana sarrafa su ta hanyar ruwa, kuma ƙarfin matsawa na iya biyan buƙatun iyakar juzu'i.

■ Ana shigar da kayan aiki a cikin akwatin sandal. Tsarin kayan gyare-gyaren ya haɗa da nau'in collet tare da tsaka-tsaki na tsakiya da biyu na ƙarewa, da kuma tsaka-tsakin tsaka-tsalle da biyu na ƙarewa.

Dangane da sauƙin nakasar halaye na manne sassa na silindi mai karen bakin ciki, yawanci ana amfani da ƙulle-ƙulle. Piston silinda ne ke motsa maƙuman don sanya su su zama naƙasa sosai don gane sassautawa ko murɗawa. Nakasar chuck na roba shine 2-3mm (diamita). Ƙunƙarar ta manne ɓangaren matsewa na ɓangaren a cikin gabaɗayan shugabanci, ƙarfin matsi daidai ne, kuma nakasar ɓangaren ƙananan ne. Lokacin da daidaiton saman ɓangaren ɓangaren matsewar ya yi kyau, za a sami daidaito mai girma. A lokaci guda, yana da mahimmanci don rage ɓarnawar sassan don sanya sassan su sami madaidaicin rataye.

■Lokacin da sassan ke da ƙayyadaddun ƙayyadaddun diamita, za'a iya shigar da katsa mai daidaitawa a cikin tsarin chuck. Ƙaƙwalwar daidaitawa shine kambori mai laushi, wanda aka gyara akan diamita na ciki na manne. Kafin amfani, yana da daidaito mai tsayi da sauri da sauƙi sauyawa.

∎ Na'urar tana ɗaukar ƙirar ƙira, kuma tana iya samun tsari iri-iri, daidaitawa da haɗin aiki bisa ga buƙatun mai amfani. Akwai zaɓuɓɓuka da yawa don gidan kayan aiki, kamar nau'in kayan aikin layi, nau'in turret da turret mai ƙarfi. Ana iya haɗa kayan aikin guda biyu zuwa ga sandar a lokaci guda ko dabam don kammala aiki ɗaya ko jere na ƙarshen ɓangaren biyun.

Haɗin mai riƙe kayan aiki: mariƙin kayan aiki biyu; kayan aikin layi biyu; mai riƙe kayan aikin wuta; Kayan aiki na layin hagu + mai riƙe kayan aiki na dama; mariƙin kayan aikin hagu + kayan aikin jere na dama.

■ Kayan aikin injin yana da cikakken rufewa da kariya, sanye take da kayan shafawa ta atomatik da na'urorin cire guntu ta atomatik, tare da kyakkyawan aikin kariya, kyakkyawan bayyanar, aiki mai sauƙi da kulawa mai dacewa.

∎ Ana iya sanye da kayan aikin injin tare da firam mai goyan baya, na'urar taimako don lodawa da saukewa, da na'urar ɗauka da saukewa ta atomatik. Duba hotunan bidiyo da na'ura.