Sirin CBS na tsakiya na tsaye-axis biyar

Siffofin

1.Main yi abũbuwan amfãni

1.1.The X-axis rungumi dabi'ar kai tsaye drive fasaha, da Y-axis rungumi dabi'ar daidaici kai tsaye drive fasaha da synchronous iko, tare da babban tura, low amo, sauri amsa gudun, da kuma m tsauri yi. Axis uku na X/Y/Z duk suna ɗaukar madaidaicin madaidaicin ra'ayin grating, tare da babban matsayi.

1.2.The high-torque torque motor korar da A-axis da C-axis don juyawa, tare da sifili watsa sarkar, sifili koma baya, da kuma mai kyau rigidity; babban madaidaicin kusurwa mai ɓoye yana samun daidaitaccen matsayi

1.3.The spindle rungumi dabi'ar high-gudun lantarki spindle tsarin da high gudun da kuma low amo.

2.High-rigidity gada tsarin

2.1.CBS jerin sun rungumi tsarin tsarin gada, kuma X / Y / Z yana samun motsi na yau da kullum, wanda nauyin nauyin A / C ba ya shafa.

2.2. A / C axis yana aiki da kansa, kuma nauyin aikin aikin ba ya shafar sauran sassan uku.

2.3.The gantry tsarin da lilo da kuma Rotary tebur goyon baya a duka iyakar iya kula da high-daidaici aiki na dogon lokaci.

3.Efficient aikin juyawa

4.High-gudun da high-rigidity Rotary tebur gane m milling da kuma juya hadaddun aiki.

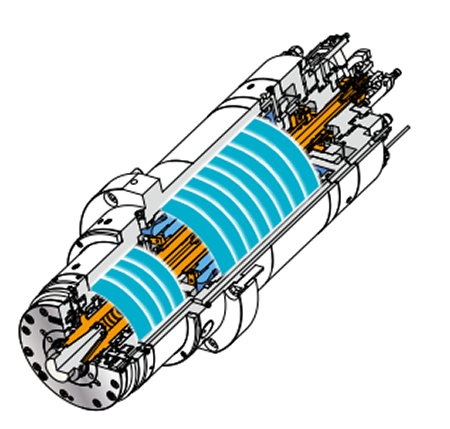

Madaidaicin tebur mai jujjuyawar axis biyar da ke motsa kai tsaye da injin juzu'i ana amfani dashi a cikin kayan aikin injin CNC kuma yana iya aiwatar da aiki na axis biyar lokaci guda. Yana da abũbuwan amfãni daga babban gudun, high daidaito, kwanciyar hankali da kuma amintacce, da kuma sauki aiki.

5.Maintaining high-daidaici machining spindles

ƙware ƙwaƙƙwaran fasahohi da haɓaka sanduna masu zaman kansu

Oturn ya ƙware ainihin fasaha kuma yana da ikon ƙirƙira, ƙira da harhada igiya. Tare da 1000m2 akai-akai taron bitar zafin jiki da kuma nagartaccen samfurin samarwa na zamani, Juya spindles suna da halaye na tsayin daka, babban sauri, babban iko, babban karfin juyi da babban abin dogaro.

HSKE40/HSKA63/HSKA100 da aka haɓaka mai zaman kansa an ɗauka. A cikin kewayon jujjuyawar sandal, ana kawar da jijjiga da girgiza don cimma daidaiton daidaito a cikin babban sauri da aiki na dogon lokaci. Tushen yana amfani da sanyaya tilas don kwantar da motsin mota da gaba da na baya.

6.Built-in motor tsarin

Ta hanyar kawar da kayan tuƙi, za a iya rage yawan girgiza yayin juyawa mai sauri, ta yadda za a inganta daidaiton injin da aka yi da kuma tsawaita rayuwar kayan aiki.

7.Spindle zafin jiki management

Ta hanyar zagayawa da mai sanyaya mai sarrafa zafin jiki, za a iya danne matsewar yanayin zafi na sandal ɗin da zafin da kowane sashi ya haifar, ta haka zai hana canje-canjen daidaiton injina.

8.Leading duniya a mikakke Motors

Motoci masu layi

8.1.An haɗa shi da motar motar linzamin kwamfuta, babu lambar sadarwa a lokacin motsi, babu asarar inji, babu watsawa baya, da saurin amsawa.

8.2. Cikakken ma'auni na gani don cikakken kulawar madauki.

Cikakken grating mai mulki, daidaiton gano matakin nanometer, ƙuduri har zuwa 0.05μm, don cimma cikakkiyar kulawar rufaffiyar madauki.

9.Excellent ergonomic zane

Dangane da ƙirar ergonomic, yana da sauƙi ga masu aiki don amfani da haɓaka aiki da kiyayewa.

9.1.Madalla da damar samun dama

Don inganta aikin samun damar yin amfani da kayan aiki, murfin da ke ƙasan ƙofar aiki yana komawa zuwa gefen ɗakin aiki don tabbatar da isasshen wurin aiki.

9.2.Babban taga don sauƙin lura da sarrafawa

Babban taga yana sauƙaƙa don lura da matsayin aiki na kayan aikin. Musamman ma, akai-akai tabbatar da yanayin yankewa da canje-canje a cikin ayyuka yayin ayyukan daidaitawa kuma ana iya kammala su cikin sauƙi, inganta ingantaccen aiki.

9.3.Centralized sanyi na kiyaye raka'a

Don inganta aikin samun damar yin amfani da kayan aiki, murfin da ke ƙasan ƙofar aiki yana komawa zuwa gefen ɗakin aiki don tabbatar da isasshen wurin aiki.

9.4.Wide ƙofar aiki don sauƙi ta hanyar crane

Lokacin yin ayyuka kamar maye gurbin kayan aiki, za a iya rage yawan aikin ma'aikata, kuma a lokaci guda, akwai isasshen sarari aiki yayin amfani da crane.

9.5.Pleasant da sada zumunci aiki panel

Ƙungiyar aiki mai jujjuyawar da ta dace da tsayin jikin mutum yana bawa mai aiki damar yin aiki da tsara na'ura a cikin yanayi mai dadi.

Ƙididdiga na Fasaha

| Abu | Saukewa: CBS200 | Saukewa: CBS200C | Saukewa: CBS300 | Saukewa: CBS300C | Saukewa: CBS400 | Saukewa: CBS400C | |

| Tafiya | Tafiyar axis X/Y/Z | 300*350*250 | 300*350*250 | 460*390*400 | |||

| Nisa daga gaban spindle zuwa cibiyar aiki | 130-380 | 130-380 | 155-555 | ||||

| Spindle | Spindle taper | E40 | E40 | E40 | |||

| Matsakaicin gudu | 30000 | 30000 | 30000 | ||||

| Ƙarfin motsi na Spindle (ci gaba / S325%) | 11/13.2 | 11/13.2 | 11/13.2 | ||||

| Juyin juzu'i na motsi (ci gaba / S325%) | 11.5/13.8 | 11.5/13.8 | 11.5/13.8 | ||||

| Ciyarwa |

Gudun sauri na axis X/Y/Z (m/min)

| 48/48/48 | 48/48/48 | 30/30/30 | |||

| Yanke ciyarwa (mm/min) | 1-24000 | 1-24000 | 1-12000 | ||||

| Tebur Rotary | Rotary tebur diamita | 200 | 300 | 400 | |||

| Nauyin kaya mai izini | 30 | 20 | 40 | 25 | 250 | 100 | |

| A-axis karkatar da kwana | ± 110° | ± 110° | ± 110° | ||||

| C-axis juyawa | 360° | 360° | 360° | ||||

| A-axis rated/max.speed | 47/70 | 47/70 | 30/60 | ||||

| A-axis Rated/max.torque | 782/1540 | 782/1540 | 940/2000 | ||||

| C-axis rated/max.speed | 200/250 | 1500/2000 | 200/250 | 1500/2000 | 100/150 | 800/1500 | |

| C-axis rated/max.torque | 92/218 | 15/30 | 92/218 | 15/30 | 185/318 | 42/60 | |

| A-axis sakawa daidaito/maimaitawa | 10/6 | 10/6 | 10/6 | ||||

| Matsayin C-axis daidaito/maimaitawa | 8/4 | 8/4 | 8/4 | ||||

| ATC | Ƙarfin mujallar kayan aiki | 16 | 16 | 26 | |||

| Tool max. diamita / tsayi | 80/200 | 80/200 | 80/200 | ||||

| Max. kayan aiki nauyi | 3 | 3 | 3 | ||||

| Lokacin canza kayan aiki (kayan aiki zuwa kayan aiki) | 4 | 4 | 4 | ||||

| Uku- axis | Jagorar axis X ( faɗin jagorar madaidaiciya / adadin silidu) | 30/2 | 30/2 | 35/2 | |||

| Jagorar axis X ( faɗin jagorar madaidaiciya / adadin silidu) | 35/2+30/2 | 35/2+30/2 | 45/2 | ||||

| Hanyar Z-axis ( faɗin jagorar madaidaiciya / adadin silidu) | 25/2 | 25/2 | 35/2 | ||||

| Ƙarfin motar linzamin X-axis (ci gaba / max.) | 1097/2750 | 1097/2750 | φ40×10 (kulle) | ||||

| Ƙarfin motar linzamin Y-axis (ci gaba / max.) | 3250/8250 | 3250/8250 |

| ||||

| Z-axis linzamin motar motsa jiki (ci gaba / max.) | 1033/1511 | 1033/1511 |

| ||||

| Daidaito | Matsayi daidaito | 0.005/300 | 0.005/300 | 0.005/300 | |||

| Maimaituwa | 0.003/300 | 0.003/300 | 0.003/300 | ||||

| Tushen wuta | Ƙarfin wutar lantarki | 25 | 30 | 25 | 30 | 30 | 35 |

| Matsin iska | ≥0.6Mpa ≥400L/min | ≥0.6Mpa ≥400L/min | ≥0.6Mpa ≥400L/min | ||||

| Girman inji | Girman inji | 1920*3030*2360 | 1920*3030*2360 | 2000*2910*2850 | |||

| Girman inji (ciki har da na'urar daukar hoto da sauran kayan aiki) | 3580*3030*2360 | 3580*3030*2360 | 3360*2910*2850 | ||||

| Nauyi | 4.8T | 4.8T | 5T | ||||

| Abu | Saukewa: CBS500 | Saukewa: CBS500C | Saukewa: CBS650 | Saukewa: CBS650C | Saukewa: CBS800 | Saukewa: CBS800C | |

| Tafiya | Tafiyar axis X/Y/Z | 500*600*450 | 650*800*560 | 800*910*560 | |||

| Nisa daga gaban spindle zuwa cibiyar aiki | 130-580 | 110-670 | 100-660 | ||||

| Spindle | Spindle taper | A63 | A63 | A63 | |||

| Matsakaicin gudu | 20000 | 20000 | 20000 | ||||

| Ƙarfin motsi na Spindle (ci gaba / S325%) | 30/34 | 30/34 | 30/34 | ||||

| Juyin juzu'i na motsi (ci gaba / S325%) | 47.7/57.3 | 47.7/57.3 | 47.7157.3 | ||||

| Ciyarwa | Gudun sauri na axis X/Y/Z (m/min)

| 48/48/48 | 48/48/48 | 48/48/48 | |||

| Yanke ciyarwa (mm/min) | 1-24000 | 1-24000 | 1-24000 | ||||

| Tebur Rotary | Rotary tebur diamita | 500 | 650 | 800 | |||

| Nauyin kaya mai izini | 600 | 240 | 800 | 400 | 1000 | 400 | |

| A-axis karkatar da kwana | ± 110° | ± 110° | ± 110° | ||||

| C-axis juyawa | 360° | 360° | 360° | ||||

| A-axis rated/max.speed | 60/80 | 40/8C | 40/80 | ||||

| A-axis Rated/max.torque | 1500/4500 | 3500/7000 | 3500/7000 | ||||

| C-axis rated/max.speed | 80/120 | 600/1000 | 50/80 | 450/800 | 50/80 | 450/800 | |

| C-axis rated/max.torque | 355/685 | 160/240 | 964/1690 | 450/900 | 964/1690 | 450/900 | |

| A-axis sakawa daidaito/maimaitawa | 10/6 | 10/6 | 10/6 | ||||

| Matsayin C-axis daidaito/maimaitawa | 8/4 | 8/4 | 8/4 | ||||

| ATC | Ƙarfin mujallar kayan aiki | 25 | 30 | 30 | |||

| Tool max. diamita / tsayi | 80/300 | 80/300 | 80/300 | ||||

| Max. kayan aiki nauyi | 8 | 8 | 8 | ||||

| Lokacin canza kayan aiki (kayan aiki zuwa kayan aiki) | 4 | 4 | 4 | ||||

| Uku- axis | Jagorar axis X ( faɗin jagorar madaidaiciya / adadin silidu) | 35/2 | 45/2 | 45/2 | |||

| Jagorar axis X ( faɗin jagorar madaidaiciya / adadin silidu) | 45/2 | 45/2 | 45/2 | ||||

| Hanyar Z-axis ( faɗin jagorar madaidaiciya / adadin silidu) | 35/2 | 35/2 | 35/2 | ||||

| Ƙarfin motar linzamin X-axis (ci gaba / max.) | 2167/5500 | 3250/8250 | 3250/8250 | ||||

| Ƙarfin motar linzamin Y-axis (ci gaba / max.) |

|

|

| ||||

| Z-axis linzamin motar motsa jiki (ci gaba / max.) | 2R40*20 (kulle) | 2R40*20 (kulle) | 2R40*20 (kulle) | ||||

| Daidaito | Matsayi daidaito | 0.005/300 | 0.005/300 | 0.005/300 | |||

| Maimaituwa | 0.003/300 | 0.003/300 | 0.003/300 | ||||

| Tushen wuta | Ƙarfin wutar lantarki | 40 | 45 | 55 | 70 | 55 | 70 |

| Matsin iska | ≥0.6Mpa ≥400L/min | ≥0.6Mpa ≥400L/min | ≥0.6Mpa ≥400L/min | ||||

| Girman inji | Girman inji | 2230*3403*3070 | 2800*5081*3500 | 2800*5081*3500 | |||

| Girman inji (ciki har da na'urar daukar hoto da sauran kayan aiki) | 2230*5540*3070 | 2800*7205*3500 | 2800*7205*3500 | ||||

| Nauyi | 11T | 15T | 15.5T | ||||

Abubuwan Gudanarwa

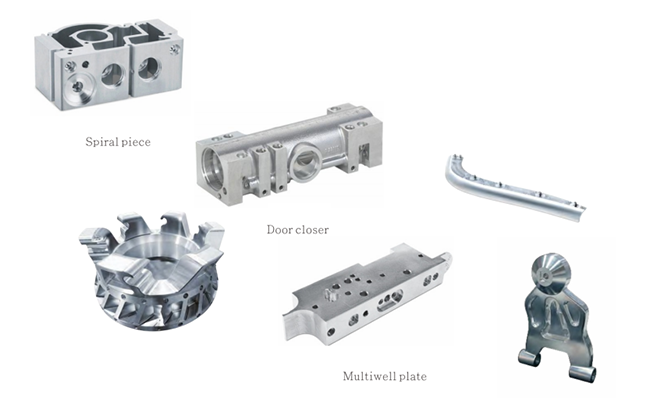

1.Masana'antar kera motoci

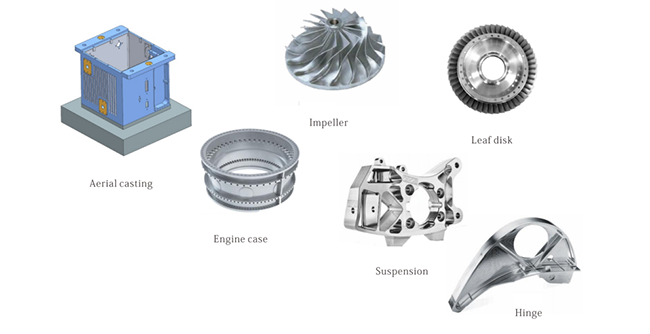

2.Aerospace

3.Injin Gina