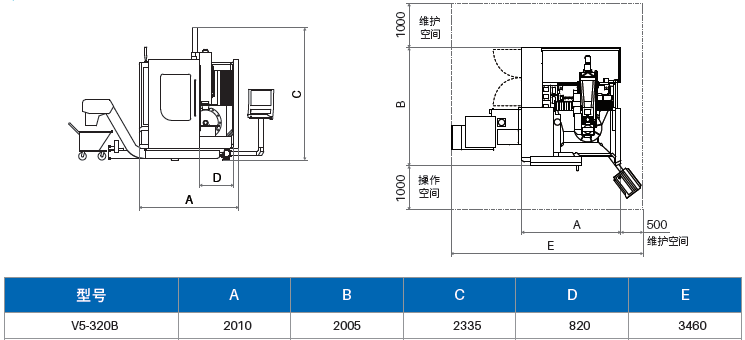

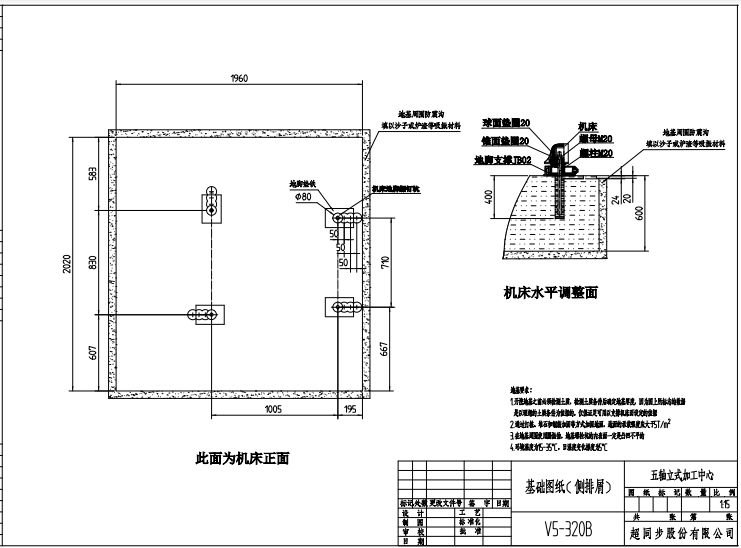

5-Axis Vertical Machining Center V5-320B

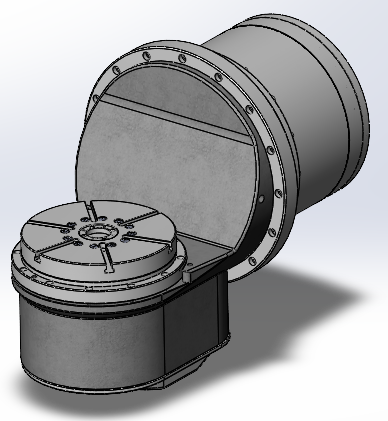

1. Gabaɗaya tsarin kayan aikin injin

V5-320B biyar-axis machining center rungumi dabi'ar barga tsarin C-dimbin yawa, ginshiƙi yana daidaitawa a kan gado, farantin nunin yana motsawa a kwance tare da ginshiƙi (yankin X), wurin zama na nunin yana motsawa a tsayi tare da farantin nunin (Y shugabanci). ), kuma babban akwati yana motsawa a tsaye tare da wurin zama na faifan (hannun Z). Teburin aiki yana ɗaukar tsarin shimfiɗar jariri kai tsaye mai tuƙi guda ɗaya, kuma alamun aikin sa daban-daban sun kai matakin ci gaba na ƙasa da ƙasa.

2. Tsarin ciyarwa

X, Y, Z-axis madaidaiciyar dogo masu jagora da sukurori na ƙwallon ƙwallon ƙafa, ƙarami mai ƙarfi da juzu'i, babban azanci, ƙarami mai saurin girgizawa, babu mai rarrafe a ƙananan gudu, daidaiton matsayi mai girma, da kyakkyawan aikin tuƙi na servo.

X, Y, Z-axis servo Motors suna da alaƙa kai tsaye tare da madaidaicin ƙwallon ƙwallon ƙwallon ƙafa ta hanyar haɗin gwiwa, rage hanyoyin haɗin kai, fahimtar watsawa mara tazara, ciyar da sassauƙa, madaidaiciyar matsayi, da daidaitaccen watsawa.

Motar servo na Z-axis tana da aikin birki. A yayin da aka samu gazawar wutar lantarki, birki na iya riƙe mashin ɗin ta atomatik ta yadda ba zai iya jujjuya ba, wanda ke taka rawar kariya ta aminci.

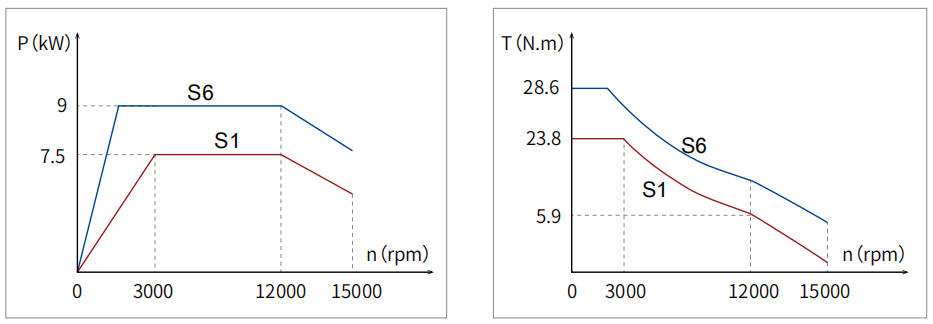

3. Wutar lantarki

Ƙaƙwalwar wutar lantarki tana ɗaukar abin da ya ɓullo da kai mai girman aiki na lantarki (ƙirƙirar haƙƙin mallaka: 202010130049.4), kuma ƙarshen sanye take da nozzles masu sanyaya don kwantar da kayan aiki. Yana da abũbuwan amfãni daga babban gudun, high daidaici, kuma high tsauri mayar da martani, kuma zai iya gane stepless gudun tsari. Gina-girma madaidaicin encoder na iya gane madaidaiciyar tasha mai tsauri da tsauri mai tsauri.

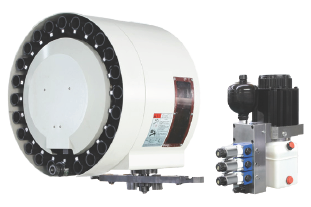

4. Mujallar kayan aiki

BT40 nau'in nau'in diski na kayan aiki, matsayi na kayan aiki 24, canjin kayan aiki ta atomatik ta mai amfani da ATC.

Duba ƙasa:

5. Juyawa

Yana ɗaukar tsarin shimfiɗar jariri kai tsaye mai ɗaukar hoto guda ɗaya, wanda ke da fa'idodin babban tsauri, babban madaidaici da amsa mai ƙarfi.

| Axis | Rated Torque Nm | Matsakaicin saurin rpm | Max. Saurin rpm | Rated Current A | Ƙarfin wutar lantarki kW |

| B | 656 | 80 | 100 | 18 | 5.5 |

| C | 172 | 100 | 130 | 6.1 | 1.8 |

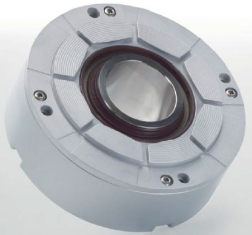

6. Cikakken rufaffiyar tsarin amsa madauki

X, Y, da Z masu linzami na layi suna sanye da jerin HEIDENHAIN LC4 cikakkun ma'auni na ƙimar darajar; B da C Rotary Tables suna sanye take da HEIDENHAIN RCN2000 jerin madaidaitan madaidaicin madaidaicin madaidaicin madaidaicin madaidaicin ra'ayi na gatari na 5, tabbatar da cewa kayan aikin injin yana da madaidaicin madaidaici. riƙe daidaito.

7. Cooling da tsarin pneumatic

An sanye shi da na'urar sanyaya ruwa don sanyaya zafin jiki akai-akai don tabbatar da cewa sandal ɗin lantarki da na'urar juyawa kai tsaye suna cikin kyakkyawan yanayin aiki kuma suna iya aiki da kyau na dogon lokaci.

Ana tace tsarin pneumatic ta hanyar abubuwan pneumatic don gane ayyukan tsaftacewa da busa ramin taper na babban shaft, kariya ta iska na babban ma'auni, da kuma jujjuya mujallu na kayan aiki da kayan aiki.

8. Tsarin lubrication na tsakiya

Tushen faifan titin jagora da na goro na dunƙule ƙwallon sun ɗauki na'urar mai mai tsaka-tsaki tare da mai mai kauri, wanda ke ba da lubrication na yau da kullun da ƙididdigewa don tabbatar da daidaito da kwanciyar hankali na dunƙule ƙwallon da layin jagora.

9. Workpiece ma'auni tsarin

Kayan aikin injin yana sanye da bincike na taɓawa HEIDENHAIN TS460 da mai karɓar siginar mara waya, wanda za'a iya shigar da shi akan sandar ta hanyar tsarin canza kayan aikin hannu ko atomatik don gane ayyukan daidaita aikin aiki, ma'aunin aiki da saitin saiti, kuma maimaita ma'aunin shine ≤ 1um (gudun bincike 1 m/min), zafin aiki shine 10 ° C zuwa 40 ° C. Ana kunna binciken taɓawa HEIDENHAIN ta hanyar canza yanayin gani. Stylus yana amfani da madaidaicin maki uku don tabbatar da kyakkyawan matsayi na kyauta. Ba shi da lalacewa yayin amfani, yana da daidaiton maimaitawa kuma yana da tsayi na dogon lokaci.

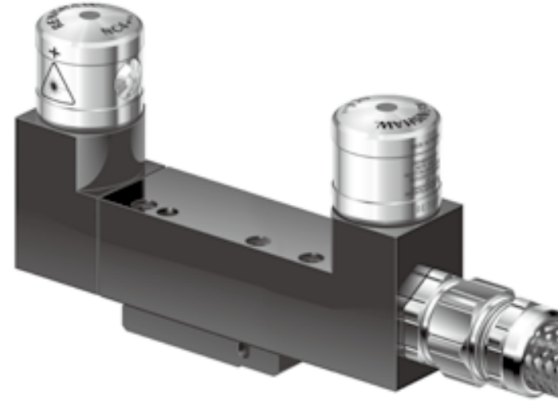

10. Tsarin auna kayan aiki

The inji kayan aiki sanye take da Renishaw NC4 Laser kayan aiki saitin kayan aiki, da ma'auni repeatability ne ± 0.1um, da kuma aiki zafin jiki ne 5 ° C zuwa 50 ° C.

11. Biyar-axis daidai calibration

Kayan aikin injin yana sanye da ƙwallan ƙira na KKH daga HEIDENHAIN, tare da jerin jerin binciken TS, don cimma daidaiton daidaitawar jujjuyawar injin kayan aikin injin, rage kurakurai yayin motsi kayan aikin injin, da cimma daidaitattun daidaito da babban maimaitawa.

12. Kariyar kayan aikin injin

Kayan aikin injin yana ɗaukar murfin kariya mai mahimmanci wanda ya dace da ka'idodin aminci don hana sanyaya da kwakwalwan kwamfuta daga fantsama, tabbatar da aiki mai aminci, da samun kyan gani. Hanyar X na kayan aikin injin yana sanye da garkuwar sulke, wanda zai iya kare hanyar dogo mai jagora da dunƙule ƙwallon ƙwallon ƙafa yadda ya kamata.

13. Yanayin aiki na kayan aiki

(1) Ƙarfin wutar lantarki: 380V± 10% 50HZ± 1HZ AC mai hawa uku

(2) Yanayin zafin jiki: 5°C-40°C

(3) Mafi kyawun zafin jiki: 22°C-24°C

(4) Dangi zafi: 20-75%

(5) Matsin tushen iska: ≥6 mashaya

(6) Yawan fitowar iskar gas: 500 L/min

14. Gabatarwar aiki na tsarin CNC

HEIDENHAIN TNC640 tsarin CNC

(1) Yawan gatari: har zuwa madaukai masu sarrafawa 24

(2) Sigar allon taɓawa tare da aikin taɓawa da yawa

(3) Shigar da shirin: Klartext conversational da G code (ISO) shirye-shirye

(4) FK shirye-shiryen kwane-kwane na kyauta: yi amfani da yaren shirye-shiryen tattaunawa na Klartext don aiwatar da shirye-shiryen kwane-kwane kyauta tare da goyan bayan hoto.

(5) Yawan niƙa da hawan hakowa

(6) Kayan aiki ramuwa: kayan aiki radiyo ramuwa da kayan aiki tsawon diyya. Zagayen bincike

(7) Yanke bayanai: Lissafin atomatik na saurin sandal, saurin yanke, ciyar da ruwa da abinci kowane da'irar

(8) Saurin sarrafa kwane-kwane na yau da kullun: dangi zuwa hanyar cibiyar kayan aiki / dangi zuwa gefen kayan aiki

(9) Parallel Run: Shirye-shirye tare da tallafin zane yayin da wani shirin ke gudana

(10) Abubuwan da aka haɗa: madaidaiciyar layi / chamfer / hanyar baka / cibiyar da'irar / radius da'irar / tangentially haɗa baka / kusurwa

(11) Gabatowa da tashi daga kwandon shara: tangential ko perpendicular/ta hanyoyin baka

(12) Tsalle shirin: subroutine/program block maimaitawa/kowane shiri na iya zama subroutine

(13) Zagayowar gwangwani: hakowa, tapping (tare da ko ba tare da firam na iyo ba), rectangular da arc cavity. Peck hakowa, reaming, m, tabo fuskantar, tabo hakowa. Nika zaren ciki da waje. Ragewar filaye masu lebur da karkata. Cikakkun injina na aljihu na rectangular da madauwari, shugabannin rectangular da madauwari. Roughing da karewa hawan keke don madaidaiciya da madauwari tsagi. Manufofin tsararru a kan da'irori da layi. Mahimman tsari: lambar QR. Sarkar kwane-kwane, aljihun kwane-kwane. Kwakwalwa tsagi don niƙa trochoidal. Zagayowar zagayowar: sassaƙa rubutu ko lambobi tare da madaidaiciyar layi ko baka.

(14) Haɗa sauyi: fassarar, juyawa, madubi, ƙira (takamaiman axis).

(15) Q siga m shirye-shirye: lissafin aiki, ma'ana aiki, parenthesis aiki, cikakken ƙima, akai-akai þ, negation, lamba ko decimal, aikin lissafin da'irar, aikin sarrafa rubutu.

(16) Programming aid: kalkuleta. Jerin duk saƙonnin kuskure na yanzu. Ayyukan taimako mai ma'ana don saƙon kuskure. TNCguide: hadedde tsarin taimako; TNC 640 yana nuna bayanai kai tsaye daga littafin mai amfani. Taimakon zane don shirye-shiryen sake zagayowar. Tubalan sharhi da manyan tubalan a cikin shirye-shiryen NC.

(17) Samun bayanai: kai tsaye amfani da ainihin matsayi a cikin shirin NC.

(18) Zane-zane masu tabbatar da shirye-shirye: Za a iya yin simintin zane na ayyukan injin koda lokacin da wani shirin ke gudana. Babban kallo/hangen gani mai girma uku/hangen sitiriyo, da jirgin sama mai karkata/zana layin 3-D. Sikelin gida.

(19) Tallafin zane-zane na shirye-shirye: Ko da wani shirin yana gudana, za a iya nuna zane-zane (2-D zanen gano rubutun hannu) na sashin shigar da shirin NC a cikin yanayin aikin gyara shirin.

(20) Shirye-shiryen da ke gudana: simintin zane-zane na ainihi yayin aiwatar da shirin niƙa. kallon sama / kallo uku / kallon sitiriyo.

(21) Lokacin sarrafawa: Yi ƙididdige lokacin sarrafawa a cikin yanayin aiki na "Gudun gwaji". Yana nuna lokacin mashin ɗin na yanzu a cikin "Shirin Run" yanayin aiki.

(22) Koma zuwa kwane-kwane: nuna lokacin aiki na yanzu a cikin yanayin aiki na "shirin yana gudana". Katsewar shirin, fita da komawa cikin kwane-kwane.

(23) Preset point management: tebur don adana duk abin da aka saita.

(24) Teburin asali: Tables na asali da yawa, ana amfani da su don adana asalin asalin aikin.

(25) 3-D Machining: Motsi Motsi na High Quality Smooth Jerk

(26) Lokacin sarrafa toshe: 0.5 ms

(27) Ƙimar shigarwa da matakin nuni: 0.1 μm

(28) Zagayowar aunawa: daidaitawar bincike. Manual ko atomatik diyya na workpiece misalignment. Saita saitattun maki da hannu ko ta atomatik. Za a iya auna kayan aiki da kayan aiki ta atomatik.

(29) Kuskuren ramuwa: Kuskuren axis na madaidaiciya da marar layi, koma baya, jujjuya kusurwa mai kaifi na motsi madauwari, kuskuren baya, haɓakar thermal. a tsaye gogayya, zamiya gogayya.

(30) Data interface: RS-232-C/V.24, har zuwa 115 kbit/s. Extended data interface of LSV2 protocol, yi amfani da HEIDENHAIN TNCremo ko software na TNCremoPlus don sarrafa TNC daga nesa ta hanyar wannan bayanan. 2 x Gigabit Ethernet 1000BASE-T dubawa. 5 x USB tashar jiragen ruwa (1 gaban USB 2.0 tashar jiragen ruwa, 4 USB 3.0 tashar jiragen ruwa).

(31) Ganewa: Kayan aikin bincike mai zaman kansa don saurin matsala da dacewa.

(32) Mai karanta CAD: nuna daidaitattun fayilolin CAD.

Babban siga

| Abu | Naúrar | Siga | |

| Kayan aiki | diamita na aiki | mm | 320 |

| Matsakaicin nauyi a kwance | kg | 150 | |

| Matsakaicin nauyi a tsaye | kg | 100 | |

| T-slot | mm | 8X10H8 | |

| Kewayon sarrafawa | Nisa tsakanin sandar ƙarshen fuska da fuskar ƙarshen aiki (Max) | mm | 430 |

| Nisa tsakanin sandar ƙarshen fuska da fuskar ƙarshen aiki (Min) | mm | 100 | |

| X axis | mm | 450 | |

| Y axis | mm | 320 | |

| Z axis | mm | 330 | |

| B axis | ° | -35°~+ 110° | |

| C axis | ° | 360° | |

| Spindle | Tafi (7 ∶ 24) |

| BT40 |

| Matsakaicin saurin gudu | rpm | 3000 | |

| Max. gudun | rpm | 15000 | |

| Matsakaicin karfin juyi S1 | Nm | 23.8 | |

| Rated Power S1 | KW | 7.5 | |

|

Axis | X axis Mai saurin wucewa | m/min | 36 |

| Y axis Mai saurin wucewa | m/min | 36 | |

| Z axis Mai saurin wucewa | m/min | 36 | |

| B axis Max. gudun | rpm | 130 | |

| C axis Max. gudun | rpm | 130 | |

| Mujallar kayan aiki | Nau'in |

| Nau'in diski |

| Hanyar zaɓin kayan aiki |

| Zaɓin kayan aiki na Bidirectional mafi kusa | |

| Iyawa | T | 24 | |

| Max. tsawon kayan aiki | mm | 150 | |

| Max. kayan aiki nauyi | kg | 7 | |

| Max. Diamita na abin yanka (Full Tool) | mm | 80 | |

| Matsakaicin diamita mai yanka diski (kayan aiki mara komai a kusa) | mm | 150 | |

| Daidaito | Matsayin gudanarwa |

| GB/T20957.4(ISO10791-4) |

| Daidaitaccen matsayi na X-axis/Y-axis/Z-axis | mm | 0.008/0.008/0.008 | |

| B-axis/C-axis daidaitaccen matsayi |

| 7"/7" | |

| X-axis/Y-axis/Z-axis maimaita daidaiton matsayi | mm | 0.006/0.006/0.006 | |

| B-axis/C-axis maimaita daidaiton matsayi |

| 5"/5" | |

| Nauyin inji | Kg | 5000 | |

| Jimlar ƙarfin lantarki | KVA | 45 | |

Daidaitaccen Lissafin Kanfigareshan

| A'a. | Suna |

| 1 | Babban abubuwan da aka gyara (ciki har da gado, ginshiƙi, farantin faifai, wurin zama na faifai, babban kaya) |

| 2 | X, Y, Z tsarin ciyarwar axis uku |

| 3 | Juya shimfiɗar shimfiɗar hannu guda ɗaya |

| 4 | Wutar lantarki BT40 |

| 5 | Tsarin sarrafa wutar lantarki (ciki har da majalisar lantarki, tsarin samar da wutar lantarki, servo module, PLC, panel na aiki, nuni, naúrar hannu, kwandishan lantarki, da sauransu) |

| 6 | Ma'aunin ƙira: HEIDENHAIN |

| 7 | Tsarin ruwa |

| 8 | Tsarin huhu |

| 9 | Tsarin lubrication na tsakiya |

| 10 | Mai ɗaukar guntu, tankin ruwa, mai tara guntu |

| 11 | Mai gadin dogo |

| 12 | Kayan aikin injin gabaɗayan murfin kariya |

| 13 | Na'urar auna aikin: HEIDENHAIN TS460 |

|

| Ma'aunin linzamin kwamfuta HEIDENHAIN |

| 14 | Kayan aikin saitin kayan aiki: HEIDENHAIN NC4 |

| 15 | Daidaitaccen daidaitaccen axis guda biyar: HEIDENHAIN KKH |

| 16 | Dangane da batu guda na amfani da software na HPMILL bayan aiwatarwa, ɗaure adireshin zahiri na kwamfutar |

| 17 | Spindle thermal elongation diyya aiki |