BOSM -6025 Na'urar Miƙa Mai Haɓakawa-Shugaban Gaggawa

1. Kayan aikiamfani:

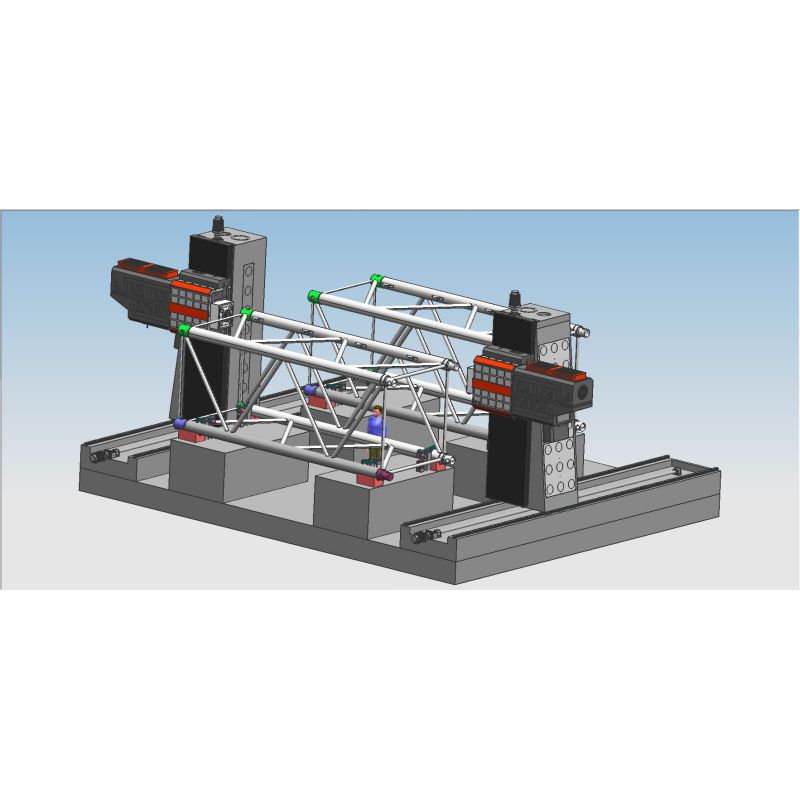

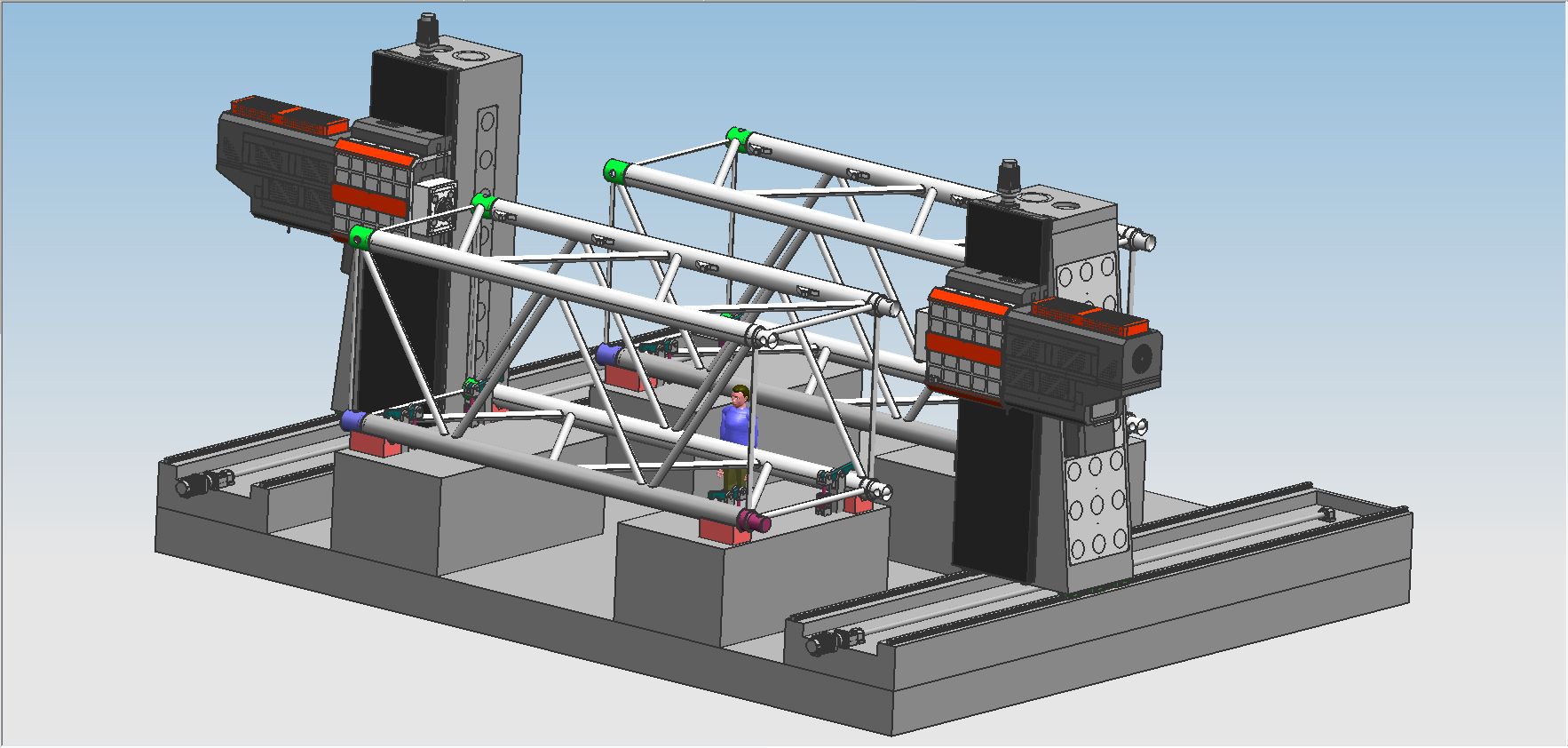

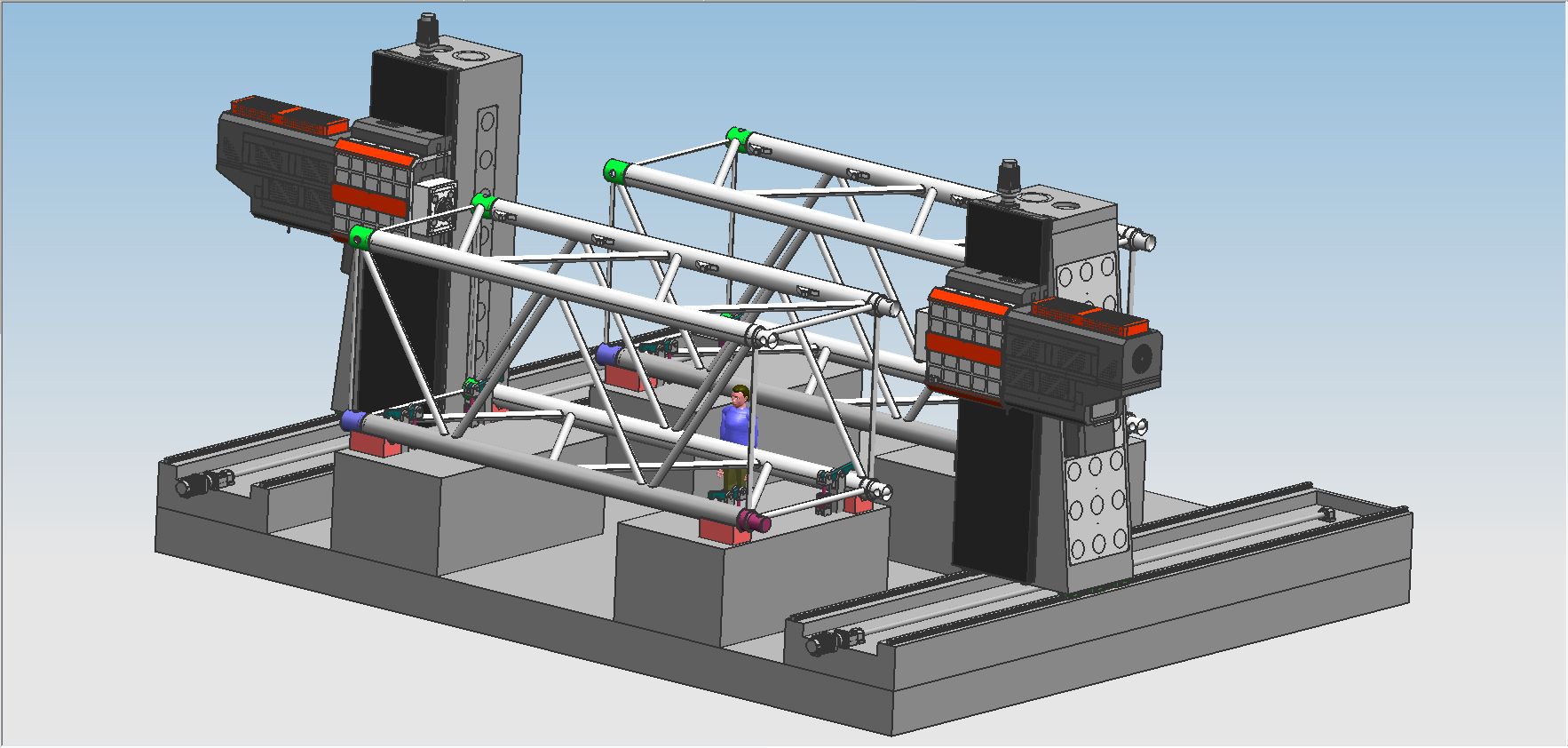

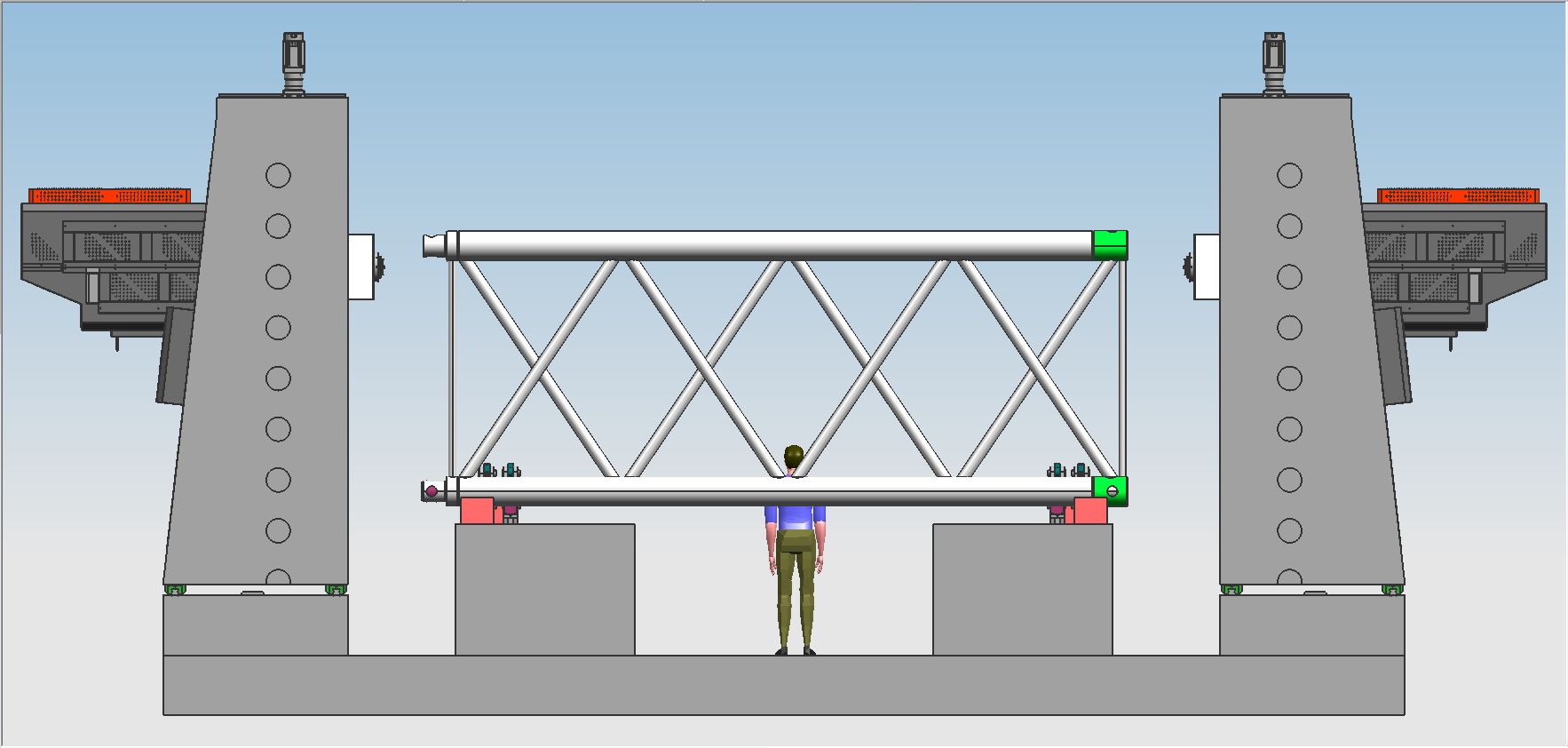

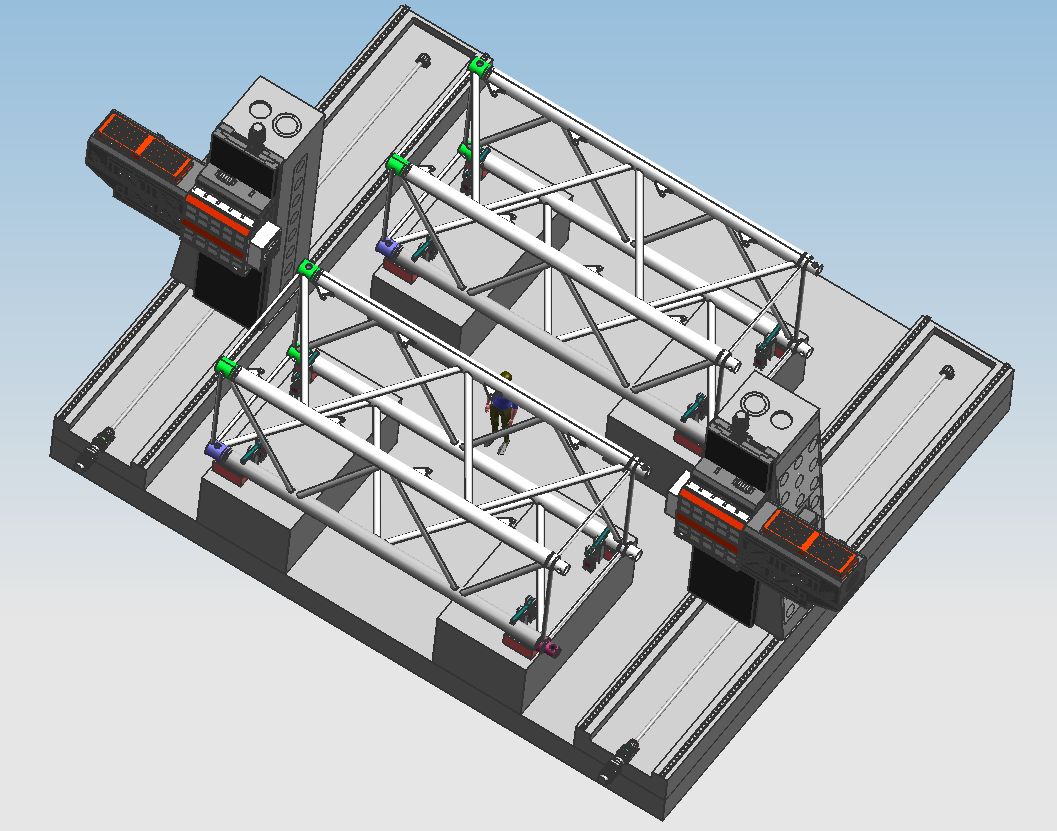

BOSM-6025 sau biyu tasha, CNC tsaye shafi m biyu-ginshiƙi kai-zuwa-kai m da niƙa inji ne na musamman inji kayan aiki ga symmetrical workpieces na yi inji. The inji kayan aiki sanye take da wani musamman m shafi da biyu sets na kwance raguna, wanda zai iya gane hakowa, milling, m da sauran aiki na workpiece a cikin tasiri bugun jini kewayon, da workpiece za a iya sarrafa a wuri a lokaci daya (babu bukata). don matsawa na biyu), saurin saukewa da saurin saukewa, saurin matsayi mai sauri, daidaitattun sarrafawa da ingantaccen aiki.

2. Tsarin kayan aiki:

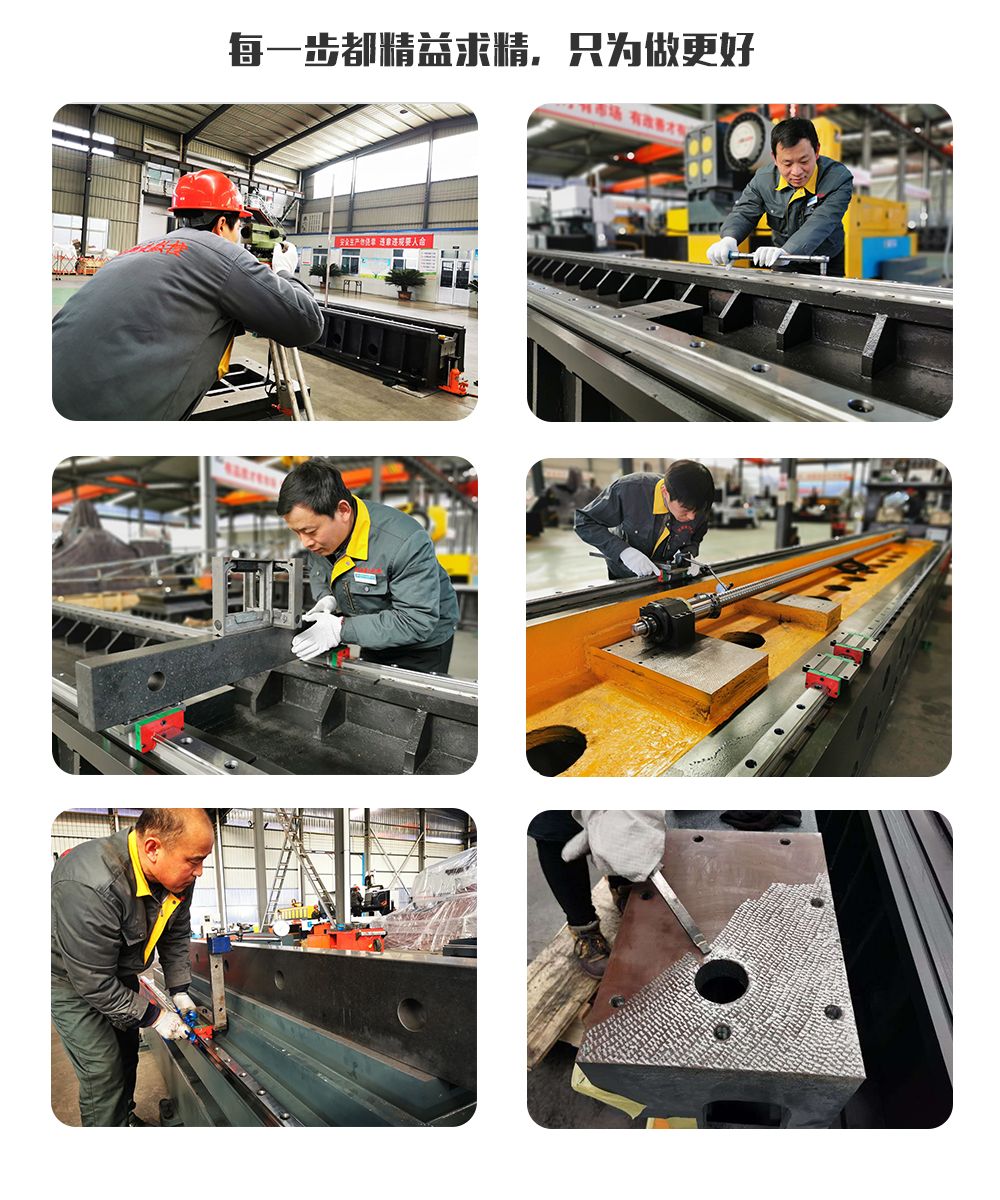

2.1. Babban kayan aikin injin

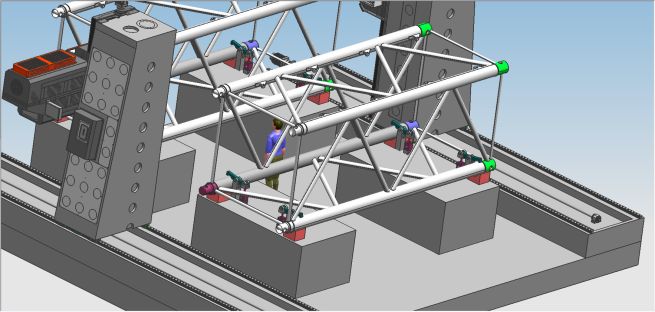

Bed, workbench, hagu da ginshiƙan dama, katako, sirdi, raguna da sauran manyan sassa duk an yi su da gyare-gyaren yashi na guduro, ƙarfe mai inganci 250 na simintin gyare-gyare, annealed a cikin ramin yashi mai zafi →vibration tsufa → zazzafan tanderun raɗaɗi → rawar jiki → m machining→ Vibration tsufa → zafi tanderun annealing → vibration tsufa → gamawa, gaba daya kawar da mummunan danniya na sassa, da kuma ci gaba da aikin sassa. Kayan aikin injin yana da ayyuka kamar milling, m, hakowa, countersinking, tapping, da dai sauransu, da kuma kayan aikin sanyaya hanya ne na waje sanyaya, The inji kayan aiki ƙunshi 6 feed gatari, wanda zai iya gane 4-axis linkage da 6-axis single- aiki. Akwai shugabannin wuta guda 2. Ana nuna jagorancin axial na kayan aikin injin da shugaban wutar lantarki a cikin hoton da ke ƙasa.

2. 2Babban tsarin tsarin ciyarwar axial watsa

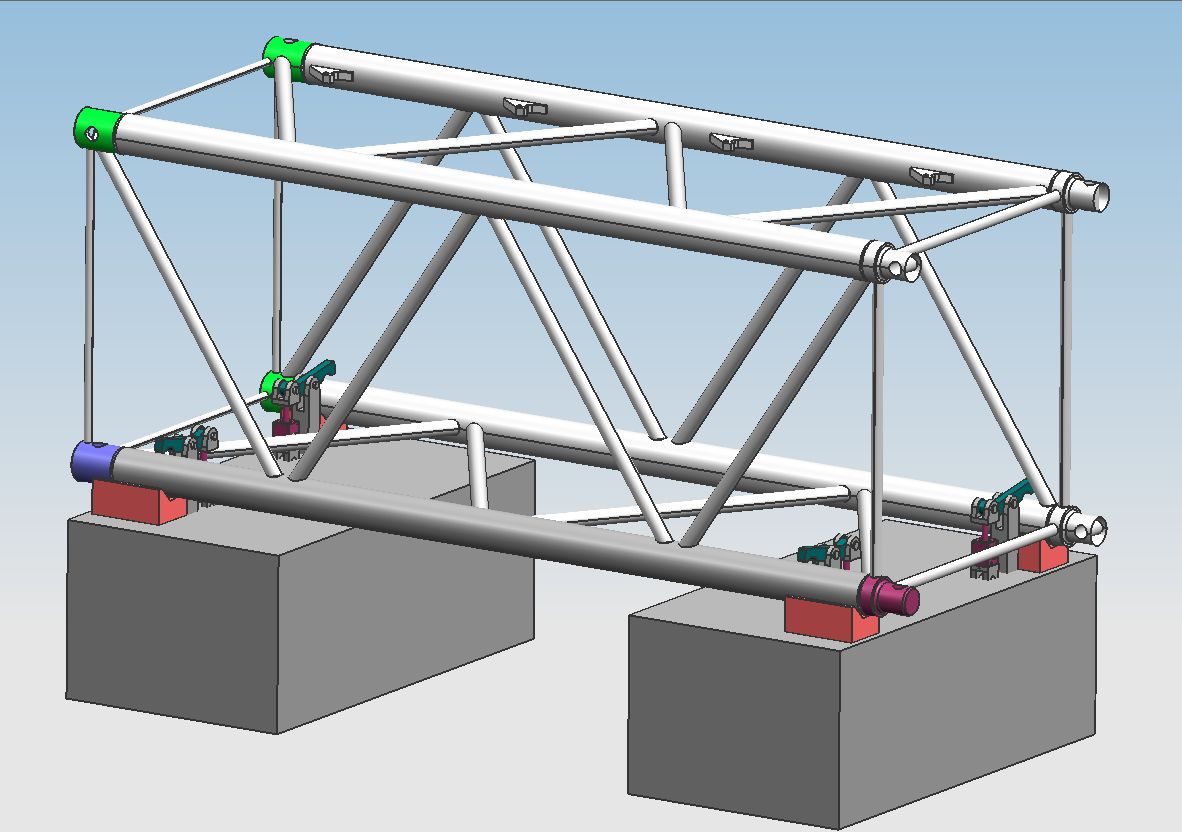

2.2.1 X 1/X2 axis: Rukunin yana amsawa a tsaye tare da titin jagora na kafaffen gado.

X-axis watsawa: AC servo motor da high-madaidaici planetary reducer Ana amfani da su fitar da ginshikan biyu ta hanyar ball dunƙule watsawa gane da mikakke motsi na X-axis.

Tsarin dogo na jagora: shimfiɗa madaidaiciyar madaidaicin layin jagora biyu masu ƙarfi.

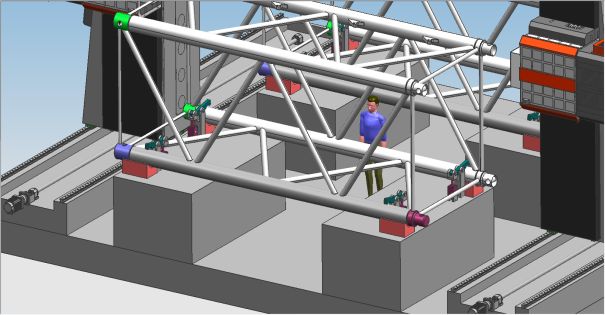

2.2.2 Y1 axis: Shugaban wutar lantarki da rago ana shigar da su a tsaye a gefen gaba na ginshiƙi, kuma suna amsawa hagu da dama tare da titin jagora na ginshiƙi.

Y1-axis watsawa: AC servo motor Ana amfani da su fitar da ball dunƙule don fitar da sirdi don motsawa, da kuma gane Y1- axis mikakke motsi.

Form dogo na jagora: 4 madaidaiciyar ragon jagora + rago mai murabba'in dogo a hade.

2.2.3 Y2 axis: An shigar da rago na biyu na shugaban wutar lantarki a tsaye a gefen gaba na ginshiƙi, kuma yana amsawa hagu da dama tare da titin jagora na ginshiƙi.

Y2-axis watsawa: AC servo motor Ana amfani da su fitar da ball dunƙule don fitar da sirdi don motsawa, da kuma gane Y2-axis linzamin kwamfuta motsi.

Form dogo na jagora: 4 madaidaiciyar ragon jagora + rago mai murabba'in dogo a hade.

2.2.4 Z1 axis: An shigar da sirdi mai zamewa shugaban wuta a tsaye a gefen gaba na ginshiƙi na dama, kuma yana maida sama da ƙasa tare da layin jagorar ginshiƙi.

Z1-axis watsawa: AC servo motor da high-madaidaici planetary rage ana amfani da su fitar da rago don matsawa ta cikin ball dunƙule don gane Z1-axis linear motsi.

Tsarin dogo na jagora: 2 hanyoyin jagora na layi.

2.2.5 Z2 axis: An shigar da sirdin shugaban faifan wutar lantarki a tsaye a gefen gaba na ginshiƙin dama, kuma yana maida sama da ƙasa tare da titin jagorar ginshiƙi.

Z1-axis watsawa: AC servo motor da high-madaidaici planetary rage ana amfani da su fitar da rago don matsawa ta cikin ball dunƙule don gane Z2 -axis linear motsi.

Tsarin dogo na jagora: 2 hanyoyin jagora na layi

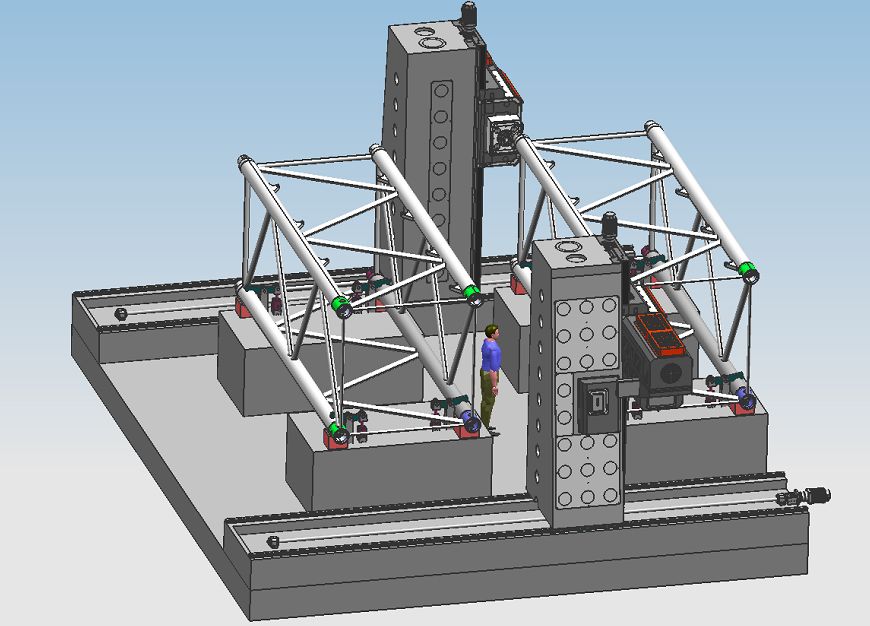

Shugaban wuta mai ban sha'awa da niƙa (ciki har da shugaban wutar lantarki 1 da 2) ragon murabba'i ne na fili, kuma jagorar motsi tana jagora ta hanyar dogo na jagora na madaidaiciya 4. Motar tana amfani da motar AC servo don fitar da madaidaicin ƙwallon ƙwallon ƙafa. Na'urar tana sanye da ma'aunin ma'aunin nitrogen. , Rage ƙarfin ɗaukar nauyi na shugaban injin akan dunƙule da motar servo. Motar Z-axis tana da aikin birki ta atomatik. A yayin da aka samu gazawar wutar lantarki, birki ta atomatik zai riƙe mashin ɗin ta yadda ba zai iya juyawa ba. Lokacin aiki, lokacin da rawar sojan ba ta taɓa kayan aikin ba, zai ciyar da sauri; lokacin da rawar sojan ya taɓa kayan aikin, zai canza ta atomatik zuwa ciyarwar aiki. Lokacin da rawar rawar soja ta shiga cikin aikin aikin, za ta canza ta atomatik zuwa saurin juyawa; lokacin da ƙarshen rawar soja ya bar aikin aiki kuma ya kai matsayin da aka saita, zai matsa zuwa matsayi na gaba don gane wurare dabam dabam ta atomatik. Kuma yana iya gane ayyukan hako rami makaho, niƙa, chamfering, ƙwanƙwasa guntu, cire guntu ta atomatik, da dai sauransu, wanda ke haɓaka yawan aiki.

Shugaban 500mm mai murabba'in bugun ragon madaurin rago yana amfani da jagororin layi maimakon abubuwan da aka saka na gargajiya don inganta daidaiton jagora yayin riƙe da tsayayyen ragon murabba'in.

2.3. Workpiece na'ura mai aiki da karfin ruwa tightening aiki

2.4Cire guntu da sanyaya

Akwai masu isar da sarƙar sarƙoƙi da lebur da aka girka a ɓangarorin biyu a ƙasan wurin aiki, kuma ana iya fitar da kwakwalwan kwamfuta ta atomatik zuwa mai ɗaukar guntu a ƙarshen ta matakai biyu na karkace da faranti na sarƙoƙi don fahimtar samarwa da wayewa. Akwai famfo mai sanyaya a cikin tanki mai sanyaya na isar da guntu, wanda za'a iya amfani dashi don sanyaya kayan aiki na waje don tabbatar da aiki da rayuwar sabis na kayan aiki, kuma ana iya sake sarrafa na'urar.

3. Cikakken tsarin sarrafa lambobi na dijital:

3.1. Tare da aikin tsinke guntu, za a iya saita lokacin karyewar guntu da sake zagayowar guntu akan mahaɗin injin-inji.

3.2. Tare da aikin ɗaga kayan aiki, ana iya saita nesa na ɗaga kayan aiki akan ƙirar injin-inji. Lokacin da aiki ya kai wannan nisa, za a ɗaga kayan aiki da sauri, sa'an nan kuma za a jefa kwakwalwan kwamfuta, sa'an nan kuma da sauri gaba zuwa saman hakowa kuma ta atomatik canza zuwa aiki.

3.3. Akwatin sarrafawa ta tsakiya da naúrar hannu sun ɗauki tsarin sarrafa lambobi kuma suna sanye da kebul na kebul da nunin ruwa na LCD. Domin sauƙaƙe shirye-shirye, ajiya, nuni da sadarwa, ƙirar aiki tana da ayyuka kamar tattaunawa na injin-na'ura, ramuwar kuskure, da ƙararrawa ta atomatik.

3.4. Kayan aiki yana da aikin samfoti da sake duba matsayi na rami kafin aiki, kuma aikin ya dace sosai.

4. Lubrication ta atomatik

Kayan aikin injin madaidaicin madaidaiciyar jagorar dogo nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan ƙwallon ƙafa, madaidaicin ƙwal ɗin dunƙule nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan motsi da sauran nau'ikan motsi masu tsayi suna sanye da tsarin lubrication na atomatik. Fam ɗin mai ta atomatik yana fitar da mai mai matsa lamba, kuma ɗakin mai mai ƙididdigewa yana shiga cikin mai. Bayan ɗakin mai ya cika da mai, lokacin da tsarin tsarin ya tashi zuwa 1.4-1.75Mpa, an rufe maɓallin matsa lamba a cikin tsarin, famfo ya tsaya, kuma bawul ɗin saukewa yana saukewa a lokaci guda. Lokacin da matsa lamba mai a hanya ya faɗi ƙasa da 0.2Mpa, mai mai ƙididdigewa ya fara cika wurin mai kuma ya cika cika mai guda ɗaya. Saboda ingantaccen man fetur na injector mai ƙididdigewa da kuma gano matsi na tsarin, samar da man fetur yana da tabbaci, tabbatar da cewa akwai fim din mai a saman kowane nau'i na kinematic, rage rikici da lalacewa, da kuma hana lalacewa tsarin ciki wanda ya haifar da zafi mai zafi , don tabbatar da daidaito da rayuwar kayan aikin injin. Idan aka kwatanta da nau'in dogo na jagorar zamewa, bibbiyu na jagorar layin dogo na birgima da aka yi amfani da su a cikin wannan kayan aikin injin yana da fa'idodi masu yawa:

① High motsi hankali, da gogayya coefficient na birgima jagora dogo ne karami, kawai 0.0025-0.01, da kuma tuki ikon da aka ƙwarai rage, wanda shi ne kawai daidai da 1 na talakawa inji. /10. ② Bambance-bambancen da ke tsakanin tsattsauran ra'ayi da tsattsauran ra'ayi yana da ƙananan ƙananan, kuma aikin da ake biyo baya yana da kyau, wato, tazarar lokaci tsakanin siginar tuki da aikin injiniya yana da ɗan gajeren lokaci, wanda ke da kyau don inganta saurin amsawa da kuma hankali na tsarin kula da lambobi.

③Ya dace da motsi na linzamin kwamfuta mai sauri, kuma saurin sa nan take ya fi sau 10 sama da na titin jagorar zamiya. ④ Yana iya gane motsi maras ƙarfi kuma ya inganta ƙarfin motsi na tsarin injiniya. ⑤Waɗanda ƙwararrun masana'antun ke samarwa, yana da madaidaicin madaidaici, haɓaka mai kyau da sauƙin kulawa.

5. Axis Laser dubawa:

Kowane injin na Bosman an daidaita shi ta hanyar interferometer Laser na kamfanin RENISHAW a cikin Burtaniya don bincika daidai da rama kuskuren farar, koma baya, daidaiton matsayi, maimaita daidaiton matsayi, da sauransu, don tabbatar da tsauri, daidaiton kwanciyar hankali da daidaiton aiki. inji . Duban wasan ƙwallon ƙafa Kowane inji yana amfani da mashin ball daga kamfanin RENISHAW na Burtaniya don daidaita daidaiton da'irar gaskiya da daidaiton na'ura, da gudanar da gwaje-gwajen yankan madauwari a lokaci guda don tabbatar da daidaiton injin 3D da daidaiton madauwari na injin.

6Yanayin kayan aikin injin:

6.1. Bukatun muhalli na amfani da kayan aiki

Tsayawa matakin zafin jiki akai-akai shine muhimmin abu don yin mashin daidaici.

(1) Abubuwan da ake buƙata na yanayi mai amfani shine -10 ℃ ~ 35 ℃, lokacin da yanayin zafin jiki shine 20 ℃, zafi ya kamata ya zama 40 ~ 75%.

(2) Don kiyaye daidaiton daidaiton kayan aikin injin a cikin kewayon ƙayyadaddun kewayon, mafi kyawun zafin jiki na yanayi yana buƙatar 15 ° C zuwa 25 ° C, da bambancin zafin jiki.

Dole ne kada ya wuce ± 2°C/24h.

6.1.2. Wutar wutar lantarki: 3 matakai, 380V, a cikin kewayon ± 10% canjin wutar lantarki, mitar wutar lantarki: 50HZ.

6.1.3. Idan wutar lantarki a yankin da ake amfani da ita ba ta da ƙarfi, kayan aikin injin ya kamata a sanye shi da ingantaccen wutar lantarki don tabbatar da aikin na'ura na yau da kullun.

6.1.4. Kayan aikin injin yakamata ya sami ingantaccen ƙasa: waya ta ƙasa shine waya tagulla, diamita na waya bai kamata ya zama ƙasa da 10mm² ba, kuma juriya na ƙasa yakamata ya zama ƙasa da 4 Ω.

6.1.5. Don tabbatar da aikin aiki na yau da kullun na kayan aiki, idan iska mai matsa lamba na tushen iska ba zai iya cika buƙatun tushen iska ba, ya kamata a sanya shi akan kayan aikin injin.

Ƙara saitin na'urar tsabtace tushen iska (dehumidification, raguwa, tacewa) kafin iska.

6.1.6. Ka kiyaye kayan aiki daga hasken rana kai tsaye, girgizawa da tushen zafi, manyan janareta masu ƙarfi, injin walda na lantarki, da sauransu, don guje wa gazawar samar da injin ko asarar daidaiton kayan aikin injin.

7. Tsigogi na fasaha:

| Samfura | 6025-6Z | |

| Girman girman aikin aiki | Tsawon × nisa × tsawo (mm) | 6000× 2300×2300 |

| Gantry iyakar ciyarwa | Nisa (mm) | 6800 |

| girman tebur aiki | Nisa X (mm) | 3000*1000 = 4 |

| Tafiya na ginshiƙi | Rukunin yana matsawa baya da baya (mm) | 7000 |

| Rago biyu daga sama da ƙasa | Sama da ƙasa bugun rago (mm) | 2500 |

| Spindle tsakiya zuwa tebur nesa jirgin sama | 0-2500 mm | |

|

Horizontal ram type hako kai ikon shugaban daya biyu

| Yawan (2) | 2 |

| Spindle taper | BT50 | |

| Diamita na hakowa (mm) | Φ2-Φ60 | |

| Diamita na taɓawa (mm) | M3-M30 | |

| Gudun juzu'i (r/min) | 30-5000 | |

| Servo spindle motor power (kw) | 37*2 | |

| Tazarar tafiya hagu da dama tsakanin ƙullun igiya biyu | 5800-6800 mm | |

| bugun ragon hagu da dama (mm) | 500 | |

| Daidaiton Matsayi Bidirectional | 300mm*300mm | ± 0.025 |

| Matsakaicin maimaituwa daidaitattun matsayi | 300mm*300mm | ± 0.02 |

| Girman Kayan Aikin Na'ura | Tsawon × nisa × tsawo (mm) | Dangane da zane-zane (idan akwai canje-canje a cikin tsarin ƙira, za mu sanar da ku) |

| Babban nauyi (t) | 72T | |