CNC Double spindle Babban aikin 1600-800-1200-1600-2000-3000 jerin

Kanfigareshan Samfur

Siffofin

TurretDficePaiki

Haɗe-haɗe tabbatacce tsarin Y-axis yana da tsauri sosai, mai nauyi, kuma yana da kyakkyawan aiki fiye da madaidaicin Y-axis.

· Sarrafa kwandon jirgi mai laushi da santsi

· Sauƙi don sarrafa filaye masu lanƙwasa da kwane-kwane

Idan aka kwatanta da "interpolation Y", "tabbatacciyar Y" tana da fa'ida a bayyane a cikin niƙan jirgin sama. Motsin "tabbatacce Y" Y-axis motsi yana daidai da axis X kuma motsi ne guda ɗaya. Motsin "interpolation Y" Y-axis motsi shine don haɗa madaidaiciyar layi ta hanyar motsi na lokaci ɗaya na axis X da Y-axis. Idan aka kwatanta da "tabbatacciyar Y" don daidaitawar jirgin niƙa, aikin axis "tabbatacce Y" yana da haske da santsi.

Kai tsayeDrafiSmElaccaSdunƙule

Babban tsauri, babban juzu'i, inganci mafi girma, mafi kyawun gamawa, ƙarin madaidaicin ƙididdiga.

Dukkanin manyan sassan injin an yi su ne da simintin ƙarfe HT300 tare da ƙarfin ɗaukar girgiza sosai.

Siffofin kayan aikin inji tare da turaren lantarki kai tsaye

●Magnetic zobe incremental encoder (sine da cosine) daidaiton matsayi: 20 arc seconds,

Daidaiton alamar C-axis: 40 arc seconds

● Saurin amsawar farawa mai sauri, adana kayan aikin injin da ingantaccen ingantaccen ƙarfin samarwa

●Ƙananan nauyin yankan, tanadin makamashi da ceton wutar lantarki, mafi kyawun kariya na kayan aikin inji da kuma tsawon rayuwar sabis

● Yadda ya kamata kawar da igiya vibration, mai kyau daidaita sakamako, mai kyau gama, da kuma inganta surface gama na workpieces.

(Fa'idodin juyawa maimakon niƙa, yanayin juyi mai wuya, ƙarancin ƙasa Ra 0.2μm)

· Motar spindle sanye take da tsarin sanyaya don murkushe tasirin canjin yanayin zafi da kuma tabbatar da cewa sandar ta ci gaba da yin aiki a koyaushe.

(Ƙarshen hanci ya ƙare daidaito yana tsakanin 0.002mm, yana tabbatar da ƙarin daidaito)

· Ƙunƙasa mai haɗaɗɗen tuƙi kai tsaye wanda aka ɗora baya, mafi dacewa shigarwa da kulawa

· A2-5: 7016AC-gaba biyu na baya biyu

A2-6: gaban NN3020+100BAR10S, baya NN3018

A2-8: gaban NN3024+BT022B*2, baya NN3022

Mai nauyi-DutyCastIronBaseAnd Cmasu kai hari

An inganta duk simintin gyare-gyare ta amfani da bincike mai iyaka (FEA) don rage murdiya da ƙarfin ɗaukar girgiza. Ana ƙarfafa simintin gyare-gyare na manyan jeri na lathes tare da haƙarƙari don haɓaka tsauri da kwanciyar hankali na zafi. Karami da simintin simintin gyare-gyare da simintin gyare-gyaren wutsiya suna ƙara haɓaka tsauri da tabbatar da daidaiton matsayi mai girma da maimaitawa.

Ƙididdiga na Fasaha

| Abu | Suna | Naúrar | 800MS | 800MSY | 600MS | 600MSY | 1200MS |

| Tafiya | Max. gadon juyawa diamita | mm | Φ700 | Φ800 | Φ700 | Φ800 | Φ700 |

| Max. machining diamita | mm | Φ540 | Φ360 | Φ540 | Φ360 | Φ530 | |

| Max. juyawa diamita akan mariƙin kayan aiki | mm | Φ350 | Φ450 | Φ350 | Φ450 | Φ350 | |

| Max. tsawon aiki | mm | 770 | 770 | 570 | 570 | 1050 | |

| Nisa tsakanin cibiyoyi biyu | mm | 770 | 770 | 570 | 570 | 1030 | |

| sandal Silinda Chuck | Leda hanci | ASA | A2-6 | A2-6 | A2-6 | A2-6 | A2-8 |

| Na'ura mai aiki da karfin ruwa Silinda / chuck | Inci | 8'' | 8'' | 8'' | 8'' | 10° | |

| Juya ta diamita na rami | mm | Φ79/66 | Φ79/66 | Φ79/66 | Φ79/66 | Φ86 | |

| Max. sanda ta rami diamita | mm | Φ65/52 | Φ66/52 | Φ65/52 | Φ65/52 | Φ76 | |

| Spindle Max. gudun | rpm | 4300 | 4000/4500 | 4300 | 4300 | 2500 | |

| Ƙarfin motsin motsi | kw | 18/22 | 18/22 | 18/22 | 18/22 | 17 | |

| Juyin juzu'i na motsi | Nm | 91-227 | 91/227 | 91-227 | 91-227 | 170/400 | |

| Sub-spindle Silinda Chuck

| Sub-Leda hanci | ASA | A2-6 | A2-6 | A2-6 | A2-6 | A2-6 |

| Sub-Na'ura mai aiki da karfin ruwa Silinda / chuck | Inci | 8” | 8” | 8” | 8” | 8" | |

| Sub-Juya ta diamita na rami | mm | Φ66 | Φ66 | Φ79/66 | Φ66 | Φ66 | |

| Sub-Max. sanda ta rami diamita | mm | Φ52 | Φ52 | Φ52 | Φ52 | Φ52 | |

| Sub-Spindle Max. gudun | rpm | 4300 | 4300 | 4300 | 4300 | 4300 | |

| Sub-Ƙarfin motsin motsi | kw | 18/22 | 18/22 | 18/22 | 18/22 | 18/22 | |

| X/ZN/S axis feed sigogi | X ikon mota | kw | 3 | 3 | 3 | 3 | 3 |

| Y karfin mota | kw | - | 1.8 | - | 1.8 | - | |

| Z motor iko | kw | 3 | 3 | 3 | 3 | 3 | |

| Sikon mota | Kw | 3 | 3 | 3 | 3 | - | |

| Xtafiya axis | mm | 320 | 215 | 315 | 215 | 313 | |

| Ytafiya axis | mm | - | - | - | 100±50 | - | |

| Ztafiya axis | mm | 80 | 820 | 620 | 620 | 1210 | |

| X/Z axis dogo bayani dalla-dalla | takamaiman | 45 abin nadi | 45abin nadi | 45 abin nadi | 45 abin nadi | 45abin nadi | |

| Y axis dogo bayani dalla-dalla | takamaiman | - | - | - | - | - | |

| S axis tafiya | mm | 770 | 770 | 570 | 570 | 880 | |

| Xaxis sauri motsi | mm/min | 24 | 24 | 24 | 24 | 24 | |

| Zaxis sauri motsi | mm/min | 24 | 24 | 24 | 24 | 24 | |

| Yaxis sauri motsi | mm/min | - | 8 | - | 8 | - | |

| Saxis sauri motsi | mm/min | 24 | 24 | 24 | 24 | 24 | |

| Servo iko Turret sigogi | Nau'in turret Power | / | Servo turret | Servo turret | Servo turret | Servo turret | Servo turret |

| Tashar kayan aiki | / | BMT55 | BMT55MY | BMT55 | BMT55MY | BMT65 | |

| M motor iko | kw | 5.5 | 5.5 | 5.5 | 5.5 | 7.5 | |

| M axis karfin juyi | Nm | 35 | 35 | 35 | 35 | 47.8 | |

| Shugaban wutar lantarki Max. gudun | rpm | 6000 | 6000 | 6000 | 6000 | 6000 | |

| Ƙayyadaddun kayan aiki na diamita na waje | mm | 25*25 | 25*25 | 25*25 | 25*25 | 25*25 | |

| Ƙayyadaddun kayan aiki na diamita na ciki | mm | Φ40 | Φ50 | Φ40 | Φ40 | Φ50 | |

| Lokacin canza kayan aiki kusa | dakika | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | |

| Matsayi daidaito | / | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 | |

| Maimaita daidaiton matsayi | / | ±0.003 | ±0.003 | ±0.003 | ±0.003 | ±0.003 | |

| Siffofin Tailstock | Wutar lantarki mai shirye-shirye | / | - | - | - | - | - |

| Tailstock Max. tafiya | mm | - | |||||

| Diamita na hannun riga | mm | - | |||||

| Tafiya hannun riga | mm | - | |||||

| Tafar hannu | / | - | |||||

| Girma | Gabaɗaya girma | m | 3100*2250*2100 | 3500*2250*2100 | 3100*2110*1800 | 3100*2250*2100 | 3900*2400*2100 |

| Nauyin inji kusan. | kg | 5600 | 7000 | 5500 | 5600 | 7600 | |

| Sauran | Yanke ƙarar tankin ruwa | L | 250 | 250 | 250 | 250 | 300 |

| Ruwa mai sanyaya wutar lantarki | kw | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | |

| Akwatin naúrar na'ura mai ɗaukar hoto | L | 40 | 40 | 40 | 40 | 40 | |

| Na'ura mai aiki da karfin ruwa famfo motor | kw | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Ƙarar tankin mai mai lubricating | L | 2 | 2 | 2 | 2 | 2 | |

| Atomatik lubrication famfo ikon | kw | 50 | 50 | 50 | 50 | 50 |

| Abu | Suna | Naúrar | 1200MSY | 1600MS | 1600MSY | 2000MS | 2000MSY |

| Tafiya | Max. gadon juyawa diamita | mm | Φ800 | Φ700 | Φ800 | Φ700 | Φ800 |

| Max. machining diamita | mm | Φ400 | Φ530 | Φ400 | Φ530 | Φ400 | |

| Max. juyawa diamita akan mariƙin kayan aiki | mm | Φ450 | Φ350 | Φ450 | Φ350 | Φ450 | |

| Max. tsawon aiki | mm | 970 | 1450 | 1370 | 2030 | 2030 | |

| Nisa tsakanin cibiyoyi biyu | mm | 1030 | 1030 | 1030 | 2030 | 2030 | |

| sandal Silinda Chuck | Leda hanci | ASA | A2-8 | A2-8 | A2-8 | A2-8 | A2-8 |

| Na'ura mai aiki da karfin ruwa Silinda / chuck | Inci | 10" | 10° | 10" | 10" | 10" | |

| Juya ta diamita na rami | mm | Φ86 | Φ86 | Φ86 | Φ86 | Φ86 | |

| Max. sanda ta rami diamita | mm | Φ76 | Φ76 | Φ76 | Φ76 | Φ76 | |

| Spindle Max. gudun | rpm | 2500 | 2500 | 2500 | 2500 | 2500 | |

| Ƙarfin motsin motsi | kw | 17 | 17 | 17 | 17 | 17 | |

| Juyin juzu'i na motsi | Nm | 170/400 | 170/400 | 170/400 | 170/400 | 170/400 | |

| Sub-spindle Silinda Chuck

| Sub-Leda hanci | ASA | A2-6 | A2-6 | A2-6 | A2-6 | A2-6 |

| Sub-Na'ura mai aiki da karfin ruwa Silinda / chuck | Inci | 8* | 8" | 8* | 8" | 8* | |

| Sub-Juya ta diamita na rami | mm | Φ66 | Φ66 | Φ66 | Φ66 | Φ66 | |

| Sub-Max. sanda ta rami diamita | mm | Φ52 | Φ52 | Φ52 | Φ52 | Φ52 | |

| Sub-Spindle Max. gudun | rpm | 4300 | 4300 | 4300 | 4300 | 4300 | |

| Sub-Ƙarfin motsin motsi | kw | 18/22 | 18/22 | 18/22 | 18/22 | 18/22 | |

| X/ZN/S axis feed sigogi | X ikon mota | kw | 3 | 3 | 3 | 3 | 3 |

| Y karfin mota | kw | 1.8 | - | 1.8 | - | 1.8 | |

| Z motor iko | kw | 3 | 3 | 3 | 3 | 3 | |

| Sikon mota | Kw | - | 3 | 3 | 3 | 3 | |

| Xtafiya axis | mm | 235 | 313 | 235 | 313 | 235 | |

| Ytafiya axis | mm | 100±50 | - | 120± 60 | - | 120± 60 | |

| Ztafiya axis | mm | 1100 | 1620 | 1500 | 2220 | 2100 | |

| X/Z axis dogo bayani dalla-dalla | takamaiman | 45abin nadi | 45 nadi | 45 nadi | 45 nadi | 45 nadi | |

| Y axis dogo bayani dalla-dalla | takamaiman | - | - | - | - | - | |

| S axis tafiya | mm | 880 | 880 | 880 | 2030 | 2030 | |

| Xaxis sauri motsi | mm/min | 24 | 24 | 24 | 24 | 24 | |

| Zaxis sauri motsi | mm/min | 24 | 24 | 24 | 24 | 24 | |

| Yaxis sauri motsi | mm/min | 8 | - | 8 | - | 8 | |

| Saxis sauri motsi | mm/min | 24 | 24 | 24 | 24 | 24 | |

| Servo iko Turret sigogi | Nau'in turret Power | / | Servo turret | Servo turret | Servo turret | Servo turret | Servo turret |

| Tashar kayan aiki | / | BMT65MY | BMT65 | BMT65MY | BMT65 | BMT65MY | |

| M motor iko | kw | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | |

| M axis karfin juyi | Nm | 47.8 | 47.8 | 47.8 | 47.8 | 47.8 | |

| Shugaban wutar lantarki Max. gudun | rpm | 6000 | 6000 | 6000 | 6000 | 6000 | |

| Ƙayyadaddun kayan aiki na diamita na waje | mm | 25*25 | 25*25 | 25*25 | 25*25 | 25*25 | |

| Ƙayyadaddun kayan aiki na diamita na ciki | mm | Φ50 | Φ50 | Φ50 | Φ50 | Φ50 | |

| Lokacin canza kayan aiki kusa | dakika | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | |

| Matsayi daidaito | / | ±0.005 | ± 0.005 | ± 0.005 | ± 0.005 | ± 0.005 | |

| Maimaita daidaiton matsayi | / | ±0.003 | ± 0.003 | ± 0.003 | ± 0.003 | ± 0.003 | |

| Siffofin Tailstock | Wutar lantarki mai shirye-shirye | / | - | - | - | - | - |

| Tailstock Max. tafiya | mm | - | - | - | - | - | |

| Diamita na hannun riga | mm | - | - | - | - | - | |

| Tafiya hannun riga | mm | - | - | - | - | - | |

| Tafar hannu | / | - | - | - | - | - | |

| Girma | Gabaɗaya girma | m | 3900*2400*2100 | 4300*2110*2100 | 4300*2110*2100 | 4300*2110*2100 | 4300*2110*2100 |

| Nauyin inji kusan. | kg | 7800 | 8400 | 8500 | 8400 | 8500 | |

| Sauran | Yanke ƙarar tankin ruwa | L | 300 | 350 | 350 | 350 | 350 |

| Ruwa mai sanyaya wutar lantarki | kw | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | |

| Akwatin naúrar na'ura mai ɗaukar hoto | L | 40 | 40 | 40 | 40 | 40 | |

| Na'ura mai aiki da karfin ruwa famfo motor | kw | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Ƙarar tankin mai mai lubricating | L | 2 | 2 | 2 | 2 | 2 | |

| Atomatik lubrication famfo ikon | kw | 50 | 50 | 50 | 50 | 50 |

| Abu | Suna | Naúrar | 3000MS | 3000MSY | 600MSY | 800MSY | 1200MSY |

| Tafiya | Max. gadon juyawa diamita | mm | Φ700 | Φ800 | Φ800 | Φ800 | Φ800 |

| Max. machining diamita | mm | Φ530 | Φ400 | Φ320 | Φ320 | Φ320 | |

| Max. juyawa diamita akan mariƙin kayan aiki | mm | Φ350 | Φ450 | Φ450 | Φ450 | Φ450 | |

| Max. tsawon aiki | mm | 3030 | 3030 | 510 | 710 | 970 | |

| Nisa tsakanin cibiyoyi biyu | mm | 3030 | 3030 | 570 | 770 | 1030 | |

| sandal Silinda Chuck | Leda hanci | ASA | A2-8 | A2-8 | A2-6 | A2-6 | A2-8 |

| Na'ura mai aiki da karfin ruwa Silinda / chuck | Inci | 10" | 10" | 8" | 8" | 10" | |

| Juya ta diamita na rami | mm | Φ86 | Φ86 | Φ79/66 | Φ79/66 | Φ86 | |

| Max. sanda ta rami diamita | mm | Φ76 | Φ76 | Φ66/52 | Φ66/52 | Φ76 | |

| Spindle Max. gudun | rpm | 2500 | 2500 | 4300 | 4300 | 2500 | |

| Ƙarfin motsin motsi | kw | 17 | 17 | 18/22 | 18/22 | 17 | |

| Juyin juzu'i na motsi | Nm | 170/400 | 170/400 | 91-227 | 91/227 | 170/400 | |

| Sub-spindle Silinda Chuck

| Sub-Spindle hanci | ASA | A2-6 | A2-6 | A2-6 | A2-6 | A2-6 |

| Sub-Hydraulic Silinda/chuck | Inci | 8" | 8* | 8" | 8" | 8* | |

| Sub-Spindle ta diamita na rami | mm | Φ66 | Φ66 | Φ66 | Φ66 | Φ66 | |

| Sub-Max. sanda ta rami diamita | mm | Φ52 | Φ52 | Φ52 | Φ52 | Φ52 | |

| Sub-Spindle Max. gudun | rpm | 4300 | 4300 | 4300 | 4300 | 4300 | |

| Ƙarfin motar Sub-Spindle | kw | 18/22 | 18/22 | 18/22 | 18/22 | 18/22 | |

| X/ZN/S axis feed sigogi | X ikon mota | kw | 3 | 3 | 3 | 3 | 3 |

| Y karfin mota | kw | - | 1.8 | 1.8 | 1.8 | 1.8 | |

| Z motor iko | kw | 3 | 3 | 3 | 3 | 3 | |

| S ikon mota | Kw | 3 | 3 | - | 3 | 3 | |

| X axis tafiya | mm | 313 | 235 | 210 | 210 | 210 | |

| Y axis tafiya | mm | - | 120± 60 | 120± 50 | 120± 50 | 120± 60 | |

| Z axis tafiya | mm | 3220 | 3100 | 620 | 820 | 1100 | |

| X/Z axis dogo bayani dalla-dalla | takamaiman | 45 nadi | 45 nadi | 45 rola | 45 nadi | 45 nadi | |

| Y axis dogo bayani dalla-dalla | takamaiman | - | - | - | - | - | |

| S axis tafiya | mm | 3080 | 3080 | - | 770 | 880 | |

| X axis saurin motsi | mm/min | 24 | 24 | 8 | 8 | 8 | |

| Z axis saurin motsi | mm/min | 24 | 24 | 24 | 24 | 24 | |

| Y axis saurin motsi | mm/min | - | 8 | 8 | 8 | 8 | |

| S axis saurin motsawa | mm/min | 24 | 24 | 24 | 24 | 24 | |

| Servo iko Turret sigogi | Nau'in turret Power | / | Servo turret | Servo turret | Servo turret | Servo turret | Servo turret |

| Tashar kayan aiki | / | BMT65 | BMT65MY | BMT55MY-16T | BMT55MY-16T | BMT55MY-16T | |

| M motor iko | kw | 7.5 | 7.5 | 5.5 | 5.5 | 7.5 | |

| M axis karfin juyi | Nm | 47.8 | 47.8 | 35 | 35 | 47.8 | |

| Shugaban wutar lantarki Max. gudun | rpm | 6000 | 6000 | 6000 | 6000 | 6000 | |

| Ƙayyadaddun kayan aiki na diamita na waje | mm | 25*25 | 25*25 | 25*25 | 25*25 | 25*25 | |

| Ƙayyadaddun kayan aiki na diamita na ciki | mm | Φ50 | Φ50 | Φ50 | Φ50 | Φ50 | |

| Lokacin canza kayan aiki kusa | dakika | 0.2 | 0.2 | 0.15 | 0.15 | 0.15 | |

| Matsayi daidaito | / | ± 0.005 | ± 0.005 | ± 0.005 | ± 0.005 | ± 0.005 | |

| Maimaita daidaiton matsayi | / | ± 0.003 | ± 0.003 | ± 0.003 | ± 0.003 | ± 0.003 | |

| Siffofin Tailstock | Wutar lantarki mai shirye-shirye | / | - | - | - | - | - |

| Tailstock Max. tafiya | mm | - | - | - | - | - | |

| Diamita na hannun riga | mm | - | - | - | - | - | |

| Tafiya hannun riga | mm | - | - | - | - | - | |

| Tafar hannu | / | - | - | - | - | - | |

| Girma | Gabaɗaya girma | m | 6200*2300*2160 | 6200*2300*2160 | 3100*2250*2100 | 3500*2250*2100 | 3900*2400*2100 |

| Nauyin inji kusan. | kg | 15000 | 15000 | 5600 | 7000 | 7800 | |

| Sauran | Yanke ƙarar tankin ruwa | L | 485 | 485 | 250 | 250 | 300 |

| Ruwa mai sanyaya wutar lantarki | kw | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | |

| Akwatin naúrar na'ura mai ɗaukar hoto | L | 40 | 40 | 40 | 40 | 40 | |

| Na'ura mai aiki da karfin ruwa famfo motor | kw | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Ƙarar tankin mai mai lubricating | L | 2 | 2 | 2 | 2 | 2 | |

| Atomatik lubrication famfo ikon | kw | 50 | 50 | 50 | 50 | 50 |

Gabatarwar Kanfigareshan

Farashin CNC

BabbanProcingPaiki

FANUC0Tsarin i-TF PLUS yana da fasaha mai inganci mai ƙarfi da fasaha mai sarrafa servo; Fasahar sarrafa inganci mai inganci yana rage lokacin aiwatar da tsarin siginar waje bisa ga haɓakawa da raguwar yanayin aikin kuma yana haɓaka amfani da damar servo, don haka rage lokacin zagayowar shirin sarrafawa; kulawar servo mai hankali yana nufin ƙungiyar aikin sarrafa servo wanda zai iya haɓaka kansa da daidaitawa a cikin ainihin lokaci kamar yanayin kayan aikin injin kamar nauyin kaya da canjin zafin jiki, samun nasara mai sauri da daidaitaccen aiki.

BabbanEaseOf Use

FANUC0i-TF PLUS tsarin yana da babban ma'aunin ƙwaƙwalwar ajiyar shirin, ana iya amfani da katin CF azaman ƙwaƙwalwar ajiyar shirye-shirye, ana iya gudanar da shirin USB tare da dannawa ɗaya, aikin CNC-QSSR yana taimakawa kayan aikin injin cikin sauri da sauƙi shigo da mutummutumi, da tsarin zaɓin IHMI aikin. yana ba da cikakken goyon baya don aiki a kan wurin sarrafawa, kuma yana ba da bayanan kayan aiki haɗakar gudanarwa, sarrafa lokaci tsinkaya, shirye-shiryen tattaunawa mai ma'ana, guje wa karo na inji, sarrafa bayanan tattara bayanai, kula da kulawa da sauran ayyukan da ake buƙata don kowane tsari a cikin tsarin "tsari", "aiki" da "ingantawa".

BabbanOperationRci

IOlinki da FSSB na FANUC Oi-TF PLUS suna da ayyuka masu kyau na gano kuskure, wanda zai iya ƙayyade gazawar wutar lantarki na I/O module ko amplifier servo da wurin da aka cire haɗin kebul na sadarwa. Bugu da kari, I / Olinki na iya gano gajeriyar da'ira na kowane ma'anar DO; Bugu da ƙari, aikin ganewar kuskure na iya samun bayanai daban-daban na bincike akan allon CNC wanda ke taimakawa wajen yin la'akari da yanayin tsarin lokacin da ƙararrawa ya faru, yana taimaka wa masu amfani su gyara yankin da sauri.

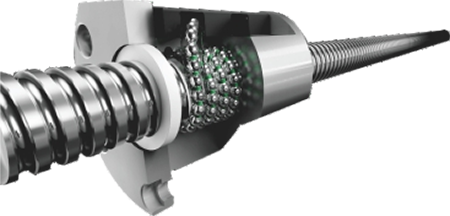

THKBdukaSma'aikata

· C3 grade, ta yin amfani da madaidaicin ƙwallon ƙwallon ƙwallon ƙafa, tare da goro pre-loading da dunƙule pre-tensioning magani pre-kawar da baya da kuma zafin jiki tashi elongation, nuna kyakkyawan matsayi da repeatability daidaito.

Motar Servo kai tsaye don rage kuskuren baya.

THKRollerLcikiGuide

· P sa matsananci-high rigidity SRG daidaici sa, mikakke jagora sifili yarda, baka yankan, bevel sabon, surface texture ne in mun gwada da uniform. Ya dace da aiki mai sauri, yana rage ƙarfin dawakai da ake buƙata don kayan aikin injin.

Mirgina maimakon zamewa, ƙananan hasarar gogayya, amsa mai mahimmanci, daidaitaccen matsayi. Zai iya ɗaukar nauyin a cikin motsin motsi lokaci guda, kuma filin tuntuɓar waƙa har yanzu yana cikin lamba mai yawa yayin ɗaukar nauyi, kuma yanke tsattsauran ra'ayi ba zai ragu ba.

· Sauƙi don haɗuwa, ƙarfi mai ƙarfi, da tsarin lubrication mai sauƙi; Yawan lalacewa yana da ƙananan ƙananan kuma rayuwar sabis yana da tsawo.

SKFBkunne/Orashin lafiyaMachine

· Man shafawa ta atomatik yana saduwa da buƙatun aikace-aikace daban-daban, dacewa da yanayin aiki daban-daban, samfuran abin dogaro, sauƙin amfani.

· Haɗu da buƙatun ɗaukar man shafawa a cikin zafin jiki mai ƙarfi, girgiza mai ƙarfi da yanayi mai haɗari.

Kowane wurin lubrication yana amfani da mai rarraba madaidaicin ƙima don sarrafa adadin mai, kuma PLC na iya sarrafa injin don samar da mai daidai.