Biyar-axis Vertical Machining Center CV Series

Siffofin

Gabatarwar inji

Jerin cibiyoyi na tsakiya na tsaye biyar-axis na CV yana da halaye na tsayin daka, babban madaidaici da ingantattun machining. Rukunin yana ɗaukar ƙirar herringbone tare da babban tazara, wanda zai iya haɓaka ƙarfin lanƙwasa da juzu'i na ginshiƙi; bench ɗin yana ɗaukar madaidaicin tazara mai madaidaici kuma yana kashe saman, don haka ƙarfin da ke kan benci ɗin ya zama iri ɗaya kuma taurin ya inganta; gado yana ɗaukar sashin giciye na trapezoidal, rage Cibiyar nauyi yana inganta ƙarfin juzu'i; gaba dayan injin yana amfani da ƙayyadaddun bincike na ƙayyadaddun abubuwa don tsara kowane sashi don samar da mafi kyawun kwanciyar hankali gabaɗaya.

Matsakaicin hanzari na axis uku mafi sauri zai iya kaiwa 48M / min, lokacin canjin kayan aiki na TT shine 2.5S kawai, an ɗora kayan aikin mujallu don 24t. Ya dace da nau'ikan nau'ikan 2D da 3D concave-convex tare da hadaddun sifofi da hadaddun cavities da saman. Har ila yau, ya dace da niƙa, hakowa, fadadawa, m, Tapping da sauran hanyoyin sarrafawa sun fi dacewa da ƙananan ƙananan da matsakaici na nau'i-nau'i iri-iri da samarwa, kuma ana iya amfani da su a cikin layi na atomatik don samar da taro.

Nunin zane mai ban sha'awa na waƙar kayan aiki, nunin faɗakarwa mai hankali, bincikar kansa da sauran ayyuka suna sa amfani da kiyaye kayan aikin injin ya fi dacewa da sauri; Ana ƙara ƙarfin karantawa zuwa layi na 3000 / na biyu, wanda ke sauƙaƙe saurin watsawa da inganci da sarrafa kan layi na manyan shirye-shirye.

RTCP (Cibiyar Kayan Aikin Juyawa) na cibiyar injina mai axis guda biyar ita ce aikin sarrafa ma'anar kayan aiki. Bayan kunna aikin RTCP, mai sarrafawa zai canza daga asali yana sarrafa ƙarshen fuskar mai riƙe da kayan aiki zuwa sarrafa madaidaicin kayan aiki. Tushen kayan aiki da ke biye zai iya rama layin da ke haifar da axis rotary. Kuskure don hana karon kayan aiki. A batu A na workpiece, tsakiyar layin kayan aiki yana canzawa kai tsaye daga matsayi na kwance zuwa matsayi na tsaye. Idan ba a gyara kuskuren linzamin kwamfuta ba, tip ɗin kayan aiki zai karkata daga aya A ko ma ya shiga cikin aikin aiki, yana haifar da haɗari mai tsanani. Saboda ci gaba da motsi na axis na jujjuyawar jujjuyawar yana haifar da canje-canje a cikin matsayi na maki A, dole ne a gyara matsayin tip na kayan aiki na asali a cikin shirin don tabbatar da cewa daidaitawar matsayi na kayan aiki koyaushe ba canzawa dangane da aya A, kamar dai Tushen kayan aiki yana motsawa tare da aya A., wannan shine tip na Kayan aiki na biye.

Wannan aikin yana da matakan 0 ~ 9, matakin na 9 shine mafi girman daidaito, yayin da matakin 1st - 8th yana ramawa kuskuren servo na baya, kuma yana ba da hanyar sarrafawa daidai santsi.

Babban-gudu da Maɗaukakin Madaidaicin Tsari Mai Girma Uku

Ƙaƙwalwar sauri mai sauri, 3D arc machining control na iya pre-karanta 2000blocks da gyare-gyaren hanya mai santsi don babban sauri da madaidaicin machining.

Babban Tsari Tsari

Inganta nau'in tsari da haɓaka rabon don haɓaka rigidity na na'ura. Siffar kayan aikin inji da ginshiƙai da haɓakar rarrabawa shine mafi kyawun sifa ta hanyar nazarin CAE. Daban-daban ingantattun matakan da ba a iya gani a waje suna nuna tsayayyen ikon yanke wanda saurin igiya ba zai iya nunawa ba.

Ƙididdiga na Fasaha

| Abu | naúrar | CV200 | CV300 | CV500 | |

| Tafiya

| Tafiyar axis X/Y/Z | mm | 500×400×330 | 700*600*500 | 700×600×500 |

| Nisa daga ƙarshen sandar fuska zuwa saman mai aiki | mm | 100-430 | 150-650 | 130-630 | |

| Nisa daga cibiyar spindle zuwa ginshiƙi jagorar dogo | mm | 412 | 628 | 628 | |

| Matsakaicin nisa tsakanin tsakiyar A-axis 90° spindle center da C-axis disk surface | mm | 235 | 360 | 310 | |

| 3 axis abinci

| X/Y/Z axis saurin ƙaura | m/min | 48/48/48 | 48/48/48 | 36/36/36 |

| Yanke ƙimar ciyarwa | mm/min | 1-24000 | 1-24000 | 1-24000 | |

| Spindle

| Ƙididdiga ƙayyadaddun spindle (diamita na shigarwa / yanayin watsawa) | mm | 95/ kai tsaye | 140/ kai tsaye | 140/ kai tsaye |

| Spindle taper | mm | BT30 | BT40 | BT40 | |

| Gudun spinle | r/min | 12000 | 12000 | 12000 | |

| Ƙarfin motsin motsi (ci gaba / S3 25%) | kW | 8.2/12 | 15/22.5 | 15/22.5 | |

| Motar Spindle Torque (Ciga gaba/S3 25%) | Nm | 26/38 | 47.8/71.7 | 47.8/71.7 | |

| Mujallar kayan aiki

| Ƙarfin mujallar | T | 21T | 24T | 24T |

| Lokacin canza kayan aiki (TT) | s | 2.5 | 4 | 4 | |

| Max.Tool diamita (cikakken kayan aiki/ kayan aiki mara komai) | mm | 80 | 70/120 | 70/120 | |

| Tsawon kayan aiki | mm | 250 | 300 | 300 | |

| Max. Nauyin kayan aiki | kg | 3 | 8 | 8 | |

| Jagora

| Jagorar axis X (girman/yawan silidu) | mm | 30/2 | 35/2 rola | 45/2 rola |

| Jagorar axis Y (girmamawa/yawan silima) |

| 30/2 | 35/2 rola | 45/2 rola | |

| Jagorar axis Z (girmamawa/yawan silima) |

| 30/2 | 35/2 rola | 45/2 rola | |

|

Dunƙule

| X-axis dunƙule |

| Φ28×16 | Φ40×16 | Φ40×16 |

| Y-axis dunƙule |

| Φ28×16 | Φ40×16 | Φ40×16 | |

| Z axis dunƙule |

| Φ32×16 | Φ40×16 | Φ40×16 | |

| Daidaito

| Matsayi daidaito | mm | ± 0.005/300 | ± 0.005/300 | ± 0.005/300 |

| Maimaituwa | mm | ± 0.003/300 | ± 0.003/300 | ± 0.003/300 | |

| 5 axis

| Hanyar tuƙi mai juyawa |

| Motar kai tsaye | Roller kamara | rola cam |

| Juyawa diamita | mm | Φ200 | Φ300*250 | φ500*400 | |

| Nauyin nauyin da aka yarda da shi na turntable (a kwance/manufa) | kg | 40/20 | 100/70 | 200 | |

| A/C-axis max. gudun | rpm | 100/230 | 60/60 | 60/60 | |

| Matsayin A-axis/maimaitawa | arc-sec | 10/6 | 15/10 | 15/10 | |

| Matsayin C-axis / maimaitawa | arc-sec | 8/4 | 15/10 | 15/10 | |

| Lubrication

| Ƙarfin naúrar mai | L | 1.8 | 1.8 | 1.8 |

| Nau'in raba mai |

| volumetric | Man shafawa | volumetric | |

| Wasu

| Bukatar iska | kg/c | ≥6 | ≥6 | ≥6 |

| Tushen iska | mm3/min | ≥0.2 | ≥0.4 | ≥0.4 | |

| karfin baturi | KVA | 10 | 22.5 | 26 | |

| Nauyin Inji (Maɗaukaki) | t | 2.9 | 7 | 8 | |

| Girman Injini (L×W×H) | mm | 1554×2346×2768 | 2248*2884*2860 | 2610×2884×3303 | |

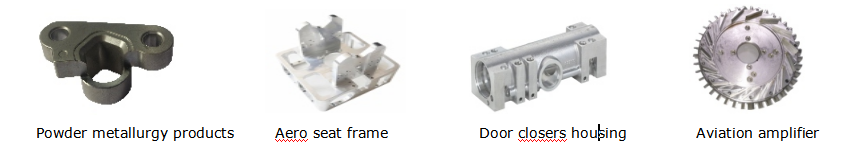

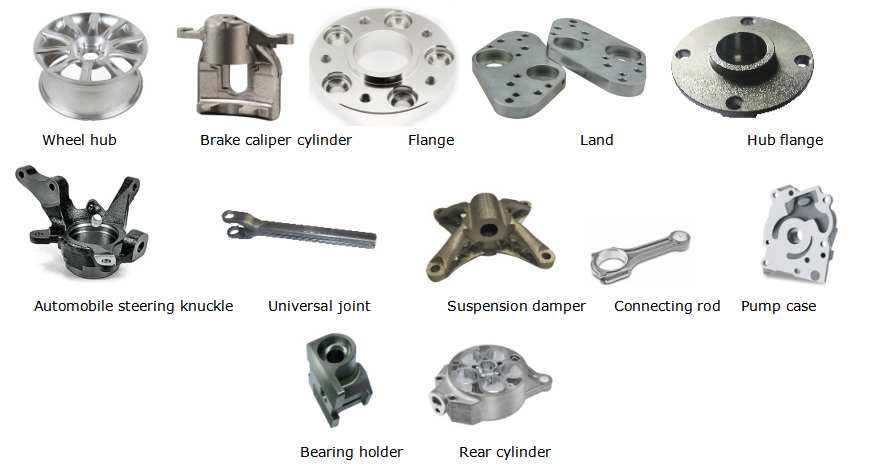

Misalin sarrafawa

1.Masana'antar kera motoci

2. Daidaitaccen daidaito

3.Masana'antar soji